Fireproof aluminum-magnesium plate

A panel and aluminum-magnesium technology, which is applied in the direction of flat/curved panel roofs, roof coverings, layered products, etc., can solve the problems of endangering life and property safety, low melting point of aluminum-magnesium panels, and roofs are easy to be burned through, etc. , to achieve the effect of light weight, high strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

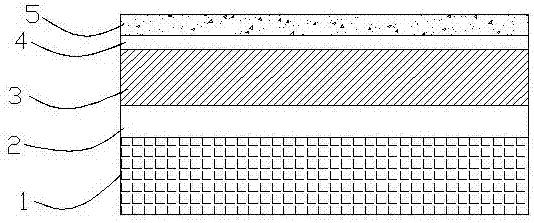

[0020] Such as figure 1 As shown, a fire-resistant aluminum-magnesium plate includes a substrate 1, and a multi-layer composite structure is also provided on the substrate 1, and the multi-layer composite structure sequentially includes: an adhesive layer 2, covering the surface of the substrate 1, for strengthening adhesion; The heat insulation layer 3 covers the surface of the bonding layer 2 for heat insulation; the heat insulation panel 4 is set on the surface of the heat insulation layer 3 to protect the board and prevent fire; the heat insulation layer 3 is filled with 2-3mm inorganic heat preservation mortar.

[0021] The working principle of the present invention: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com