Ultrahigh-speed turbine applicable to high-temperature high-back pressure dry gas seal structure

A dry gas sealing, high back pressure technology, used in mechanical equipment, engine components, machines/engines, etc., can solve the problems of low wear resistance of dynamic seals, single non-adjustable output power, unstable elastic value changes, etc. The effect of improving wear resistance and reliability, improving bearing working environment and improving working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] An ultra-high-speed turbine suitable for a high-temperature, high-backpressure dry gas sealing structure provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

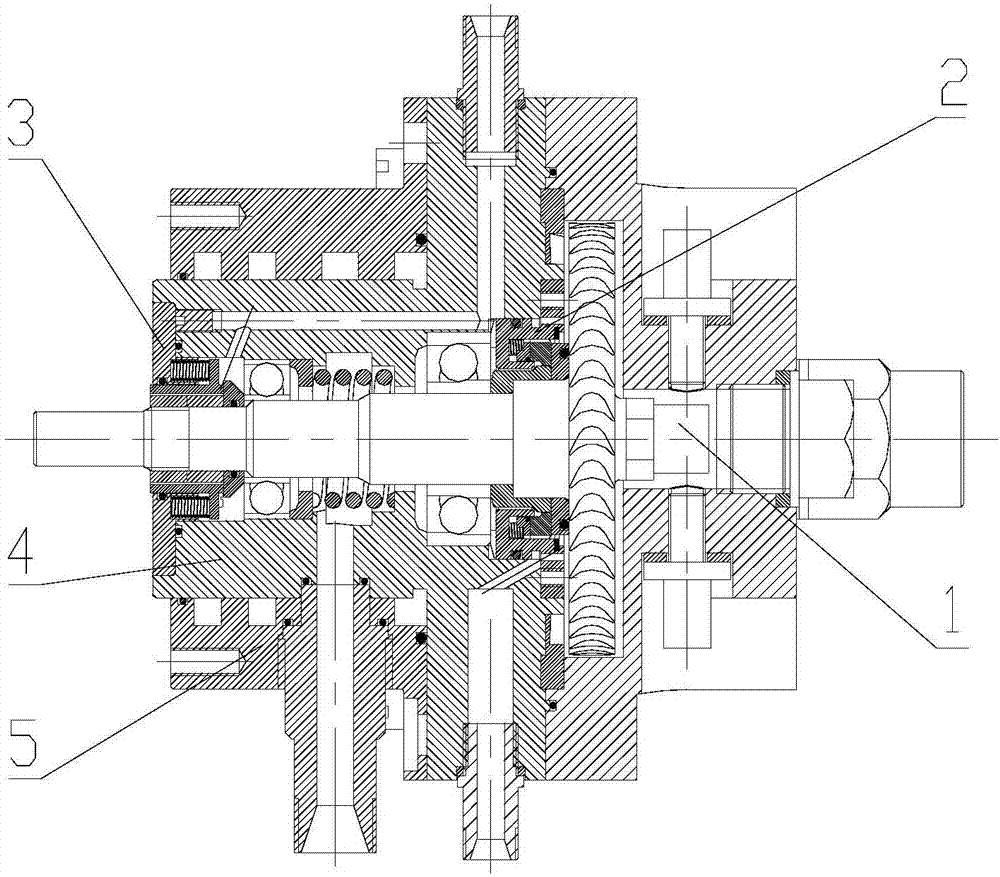

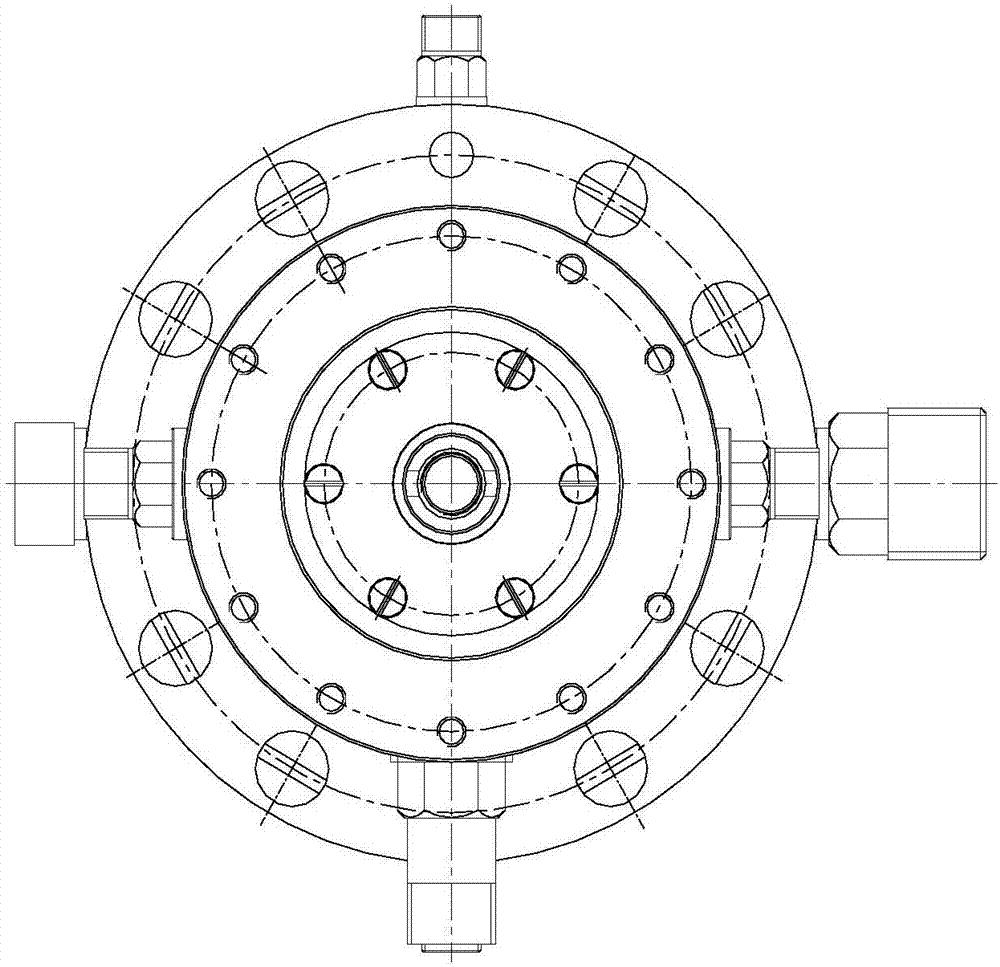

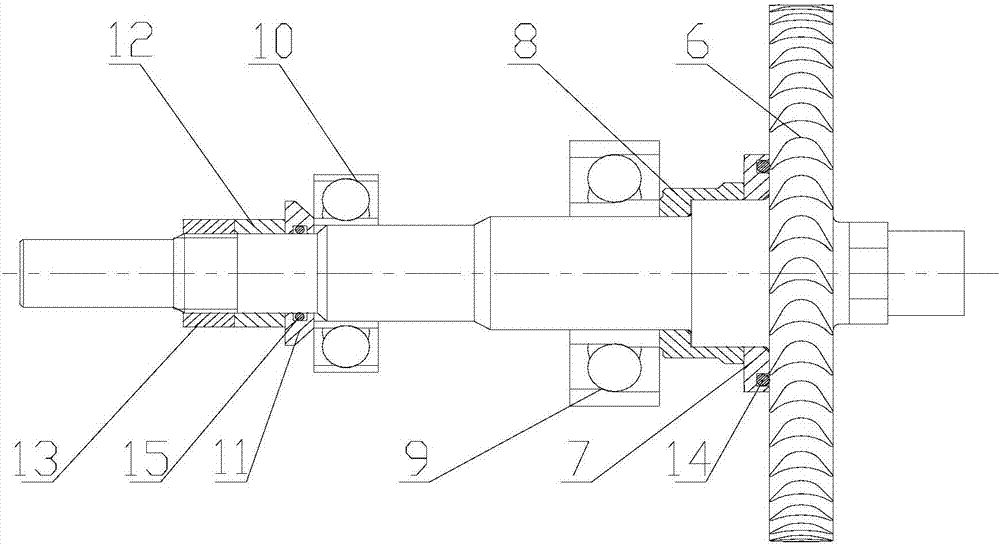

[0045] like figure 1 and figure 2 As shown, the present invention provides an ultra-high-speed turbine suitable for high temperature and high back pressure dry gas seal structure, including turbine shaft assembly 1, dry gas seal assembly 2, mechanical dynamic seal assembly 3, housing assembly 4, cooling water The sleeve assembly 5; the turbine shafting assembly 1 passes through and is installed inside the casing assembly 4, the dry gas seal assembly 2 is located inside the casing assembly 4 and connected with the turbine shafting assembly 1, and the cooling water jacket assembly 5 is positioned to install the casing assembly 1 outside, the mechanical dynamic seal assembly 3 is installed inside the housing assembly 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com