Inner ring fire cover of gas combustor

A technology of gas burner and inner ring fire, which is applied in the direction of gas fuel burner, burner, combustion method, etc. It can solve the problems of letting go of the flame, the burner is not ignited, and the fire hole is blocked, so as to prevent the flame from extinguishing and uniform burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

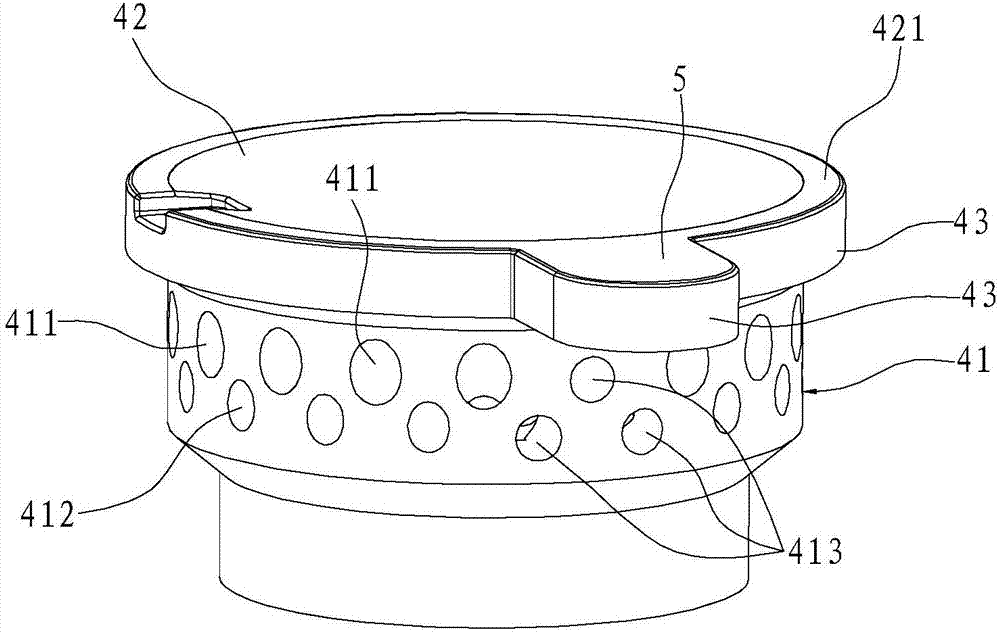

[0033] Such as Figure 6 , Figure 7 and Figure 9 As shown, the difference from Embodiment 1 is that in this embodiment, a fire hole 414 communicating with the inner ring air mixing chamber 40 is also provided on the side wall of the fire outlet 415, and the fire cover above the fire hole 414 The peripheral edge 421 of the main body 41 extends horizontally outwards to form the fire protection eaves 7 .

[0034] In this embodiment, the waterproof eaves 43 are only arranged at the bottom of the edges of the ignition needle protection umbrella 5 and the fire protection eaves 7 . Specifically, two waterproof eaves 43 are arranged opposite to the bottom of the edge of the ignition pin protection umbrella 5 , and each waterproof eaves 43 is formed by extending outwardly from the edge of the ignition needle protection umbrella 5 . The ignition hole 413 is provided on the side wall of the fire cover body 41 between the above two waterproof eaves 43 . The waterproof eaves 43 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com