Phase-lag-compensation-based same-frequency vibration force suppression method and control system of magnetically suspended flywheel

A technology of suspension control and phase lag, applied in general control systems, control/regulation systems, mechanical oscillation control, etc. The effect of robust time-varying co-frequency vibration force suppression performance, high precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

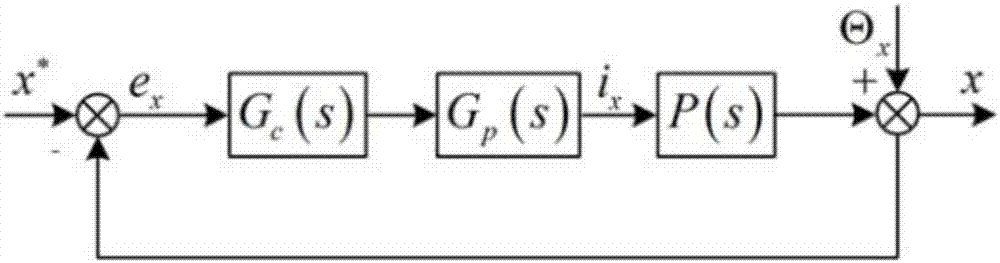

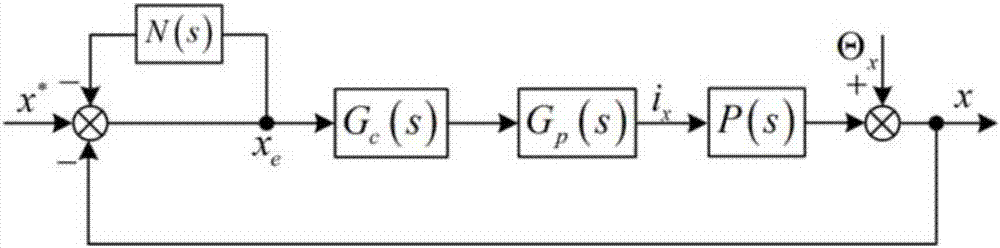

[0055] The same-frequency vibration force suppression method proposed by the present invention, the main control idea includes two aspects. On the one hand, the phase-shift notch filter is used to suppress the same-frequency current disturbance in the full speed range; on the other hand, the proportional compensation item and the additional compensation item are used to Eliminate the residual co-frequency vibration force component in the displacement stiffness as much as possible.

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation steps.

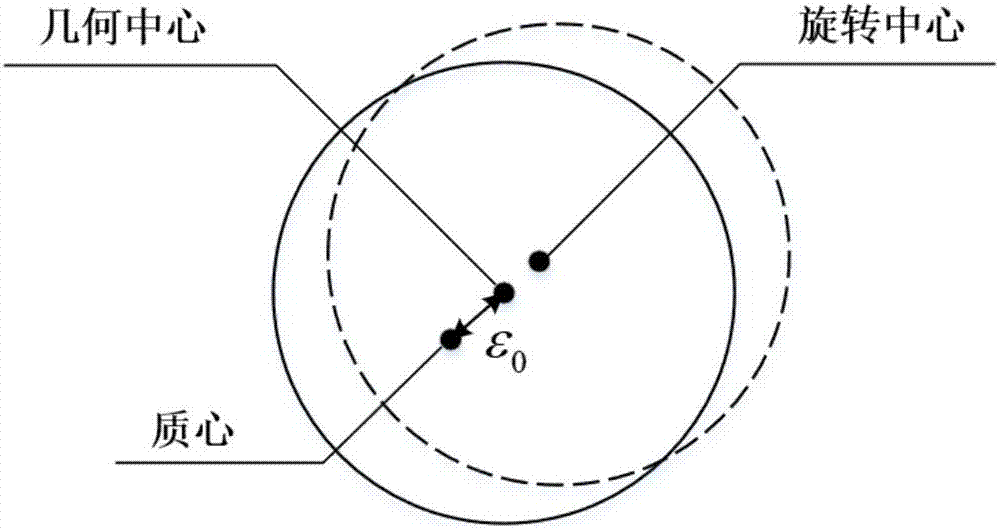

[0057] The magnetic bearing structure of the research object in the embodiment is a magnetic levitation flywheel composed of a five-degree-of-freedom permanent magnetic bias hybrid magnetic bearing. A two-degree-of-freedom radial magnetic bearing is used to control radial translational motion, and a pair of three-degree-of-freedom axial magnetic bearings a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com