Device and a method for counting layers of stacked slices by using camera array

A counting method and counting device technology, which is applied in the counting of stacked items, counting objects, counting mechanisms/items, etc., can solve problems such as splicing problems, large differences in imaging effects of stacked end faces, etc., and achieve long-term vibration interference and real-time high performance and improved resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

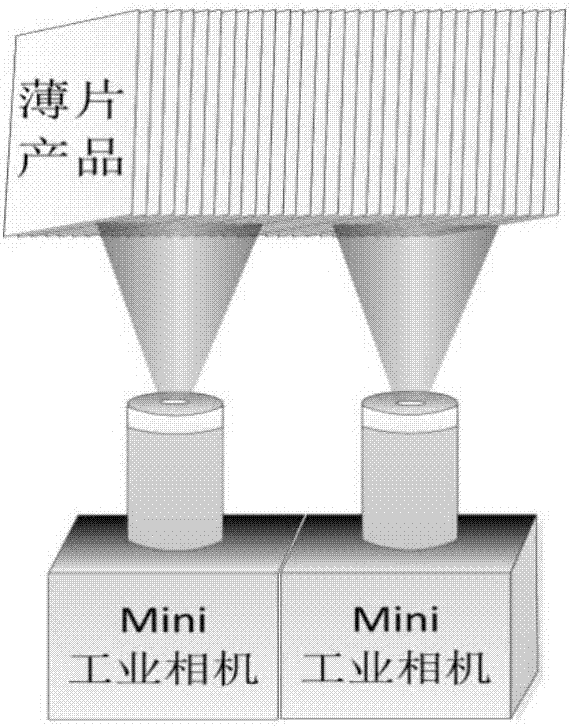

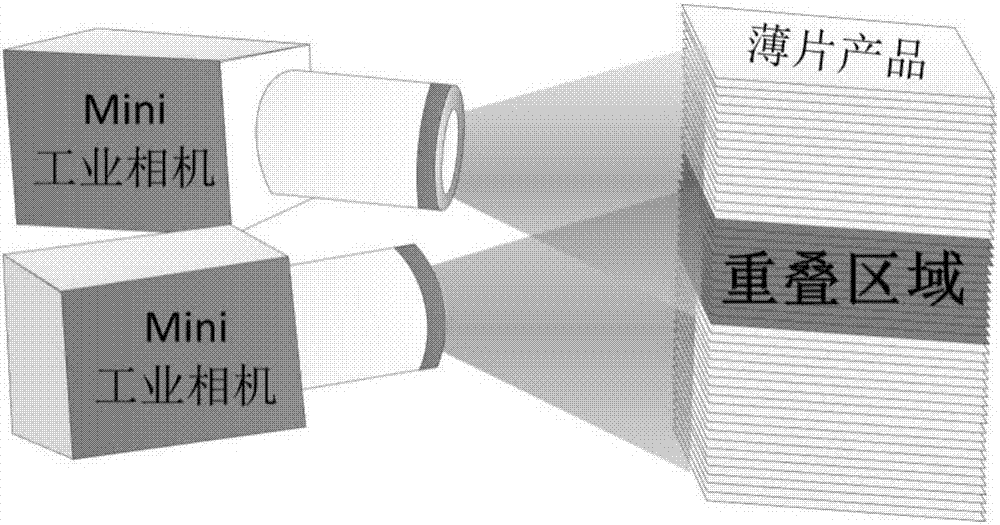

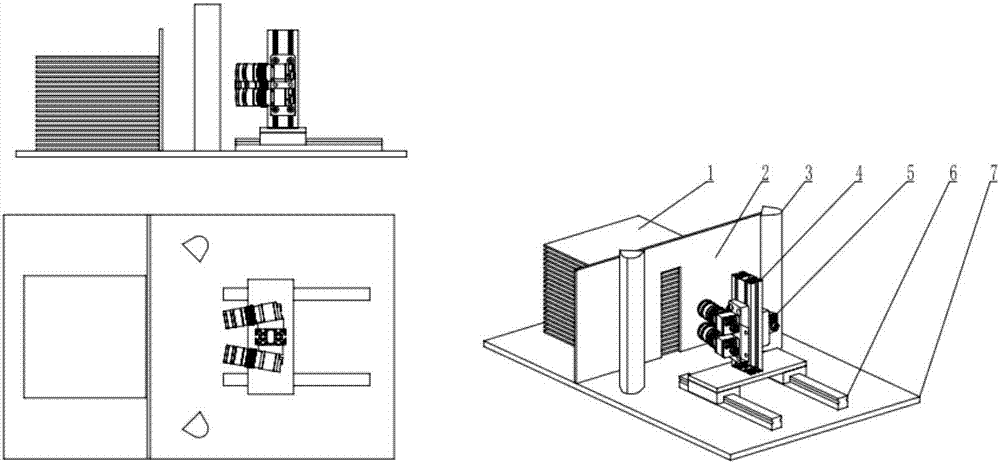

[0047] Such as figure 1 As shown, it shows that the field of view of the camera is seriously insufficient at high resolution, and the images collected by two adjacent cameras have no overlapping area, which will cause the image stitching step for the overlapping area of adjacent images to be unable to perform. The interlaced design of the present invention The hardware system solution in the form of arrayed double-row camera array imaging effectively solves the contradiction between the resolution and the field of view that has always been produced in the counting process of ultra-high stacks, such as figure 2 As shown, the solution to this problem can not only meet the requirements of splicing, but also reduce the system's requirements for high configuration of cameras and lenses while ensuring the counting accuracy, and reduce the hardware cost of the entire detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com