A multi-phase motor driver control method

A multi-phase motor and control method technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of complex engineering implementation, large calculation amount of space vector modulation method, and inability to effectively eliminate the influence of common mode voltage, etc., to achieve The effect of canceling the common mode voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] A kind of multi-phase motor driver control method of the present invention, the content of this method is as follows:

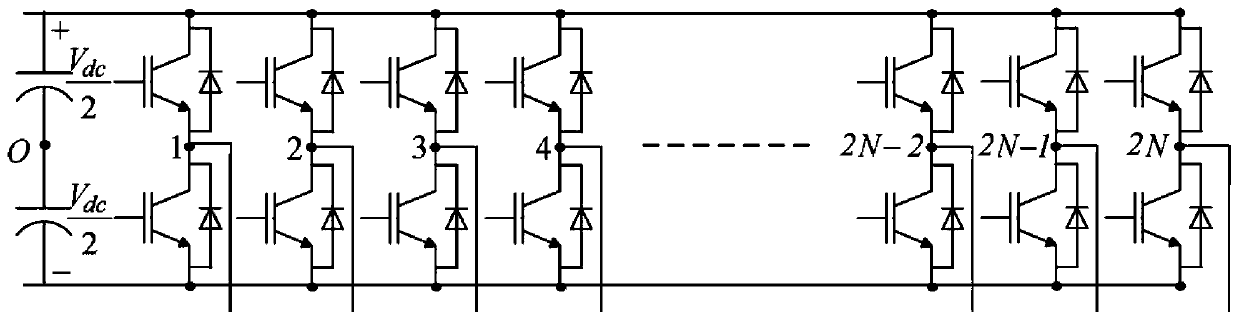

[0024] The multi-phase motor driver is composed of 2n-phase inverters, where n is a natural number, such as figure 1 As shown, among them, the first phase bridge arm and the second phase bridge arm are controlled by the first module 1, the third phase bridge arm and the fourth phase bridge arm are controlled by the second module, ..., and so on, the 2n-1th The phase bridge arm and the 2nth phase bridge arm are controlled by the nth module.

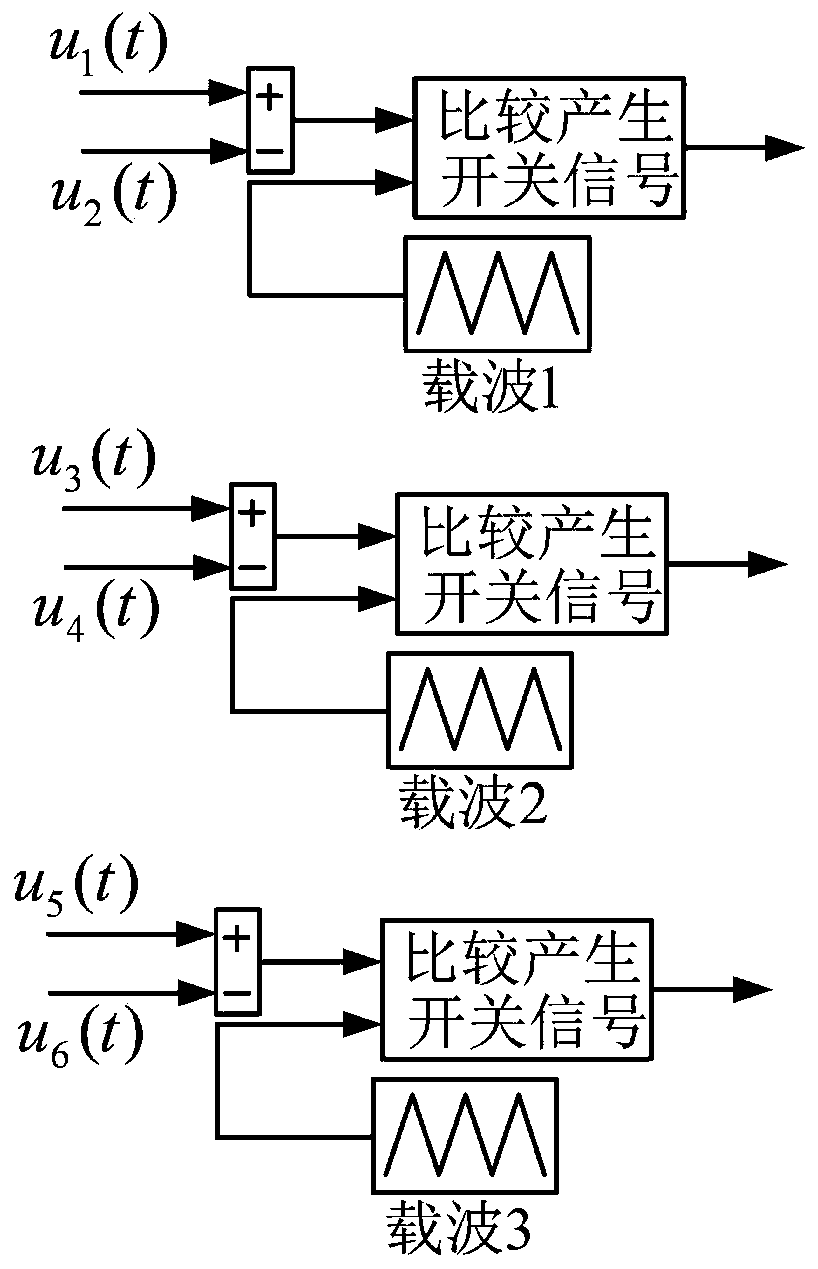

[0025] When selecting n=3 below, specify the control method of the present invention, as figure 2 As shown, the implementation steps of the control method are as follows:

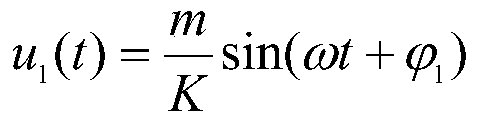

[0026] In the control of the first module, the first modulation wave is subtracted from the second modulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com