Wheel spraying protection device

A protective device and wheel technology, which is applied in the direction of the fixed wheel device, spray device, wheel, etc., can solve the problem of paint sticking on the flange surface, center hole and bolt hole cone surface, etc., and achieve a wide range of protection, advanced technology, and high performance. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

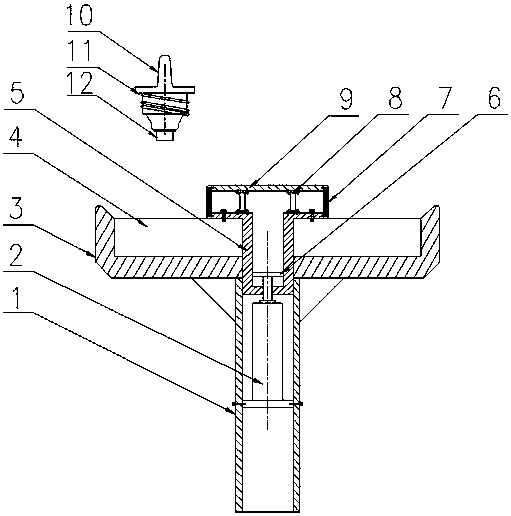

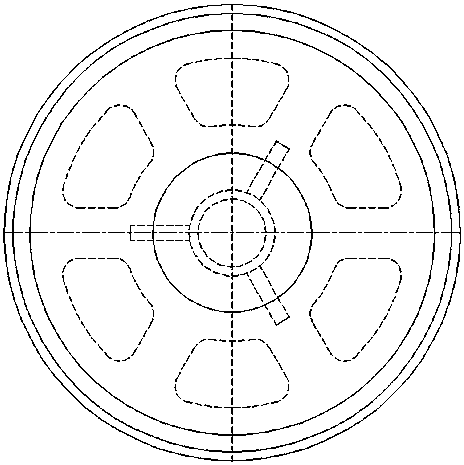

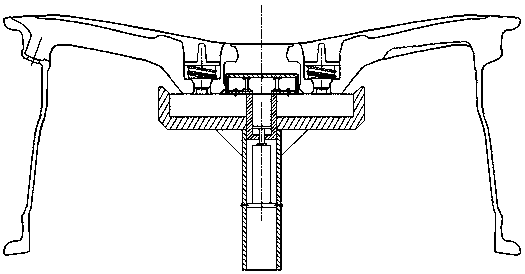

[0014] The details and working conditions of the specific device proposed by the present invention will be given below in conjunction with the description of the accompanying drawings.

[0015] A wheel spray protection device, which consists of a hollow mounting frame 1, an electric cylinder 2, a tray 3, an electromagnetic sucker 4, a sleeve 5, a piston 6, a soft rubber sleeve 7, a support column 8, an end cover 9, and a high temperature resistant plastic protective plug 10 , Spring 11 and iron post 12 form.

[0016] The hollow mounting frame 1 is used to install the device on the automatic spraying line. The tray 3 is installed above the hollow mounting frame 1 and fixed by reinforcing ribs. The electromagnetic chuck 4 is embedded in the tray 3. The electric cylinder 2 is fixed inside the hollow mounting frame 1. The output end of the cylinder 2 is connected to the piston 6, the piston 6 cooperates with the inner wall of the sleeve 5, the outer wall of the sleeve 5 is closely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com