Metal mobile phone shell processing equipment and process thereof

A technology of processing equipment and processing technology, which is applied in the field of metal mobile phone casing processing equipment and its technology, can solve the problems of hole shape, poor spacing, and high manufacturing cost of metal casings, so as to reduce processing costs, improve performance, and ensure product strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

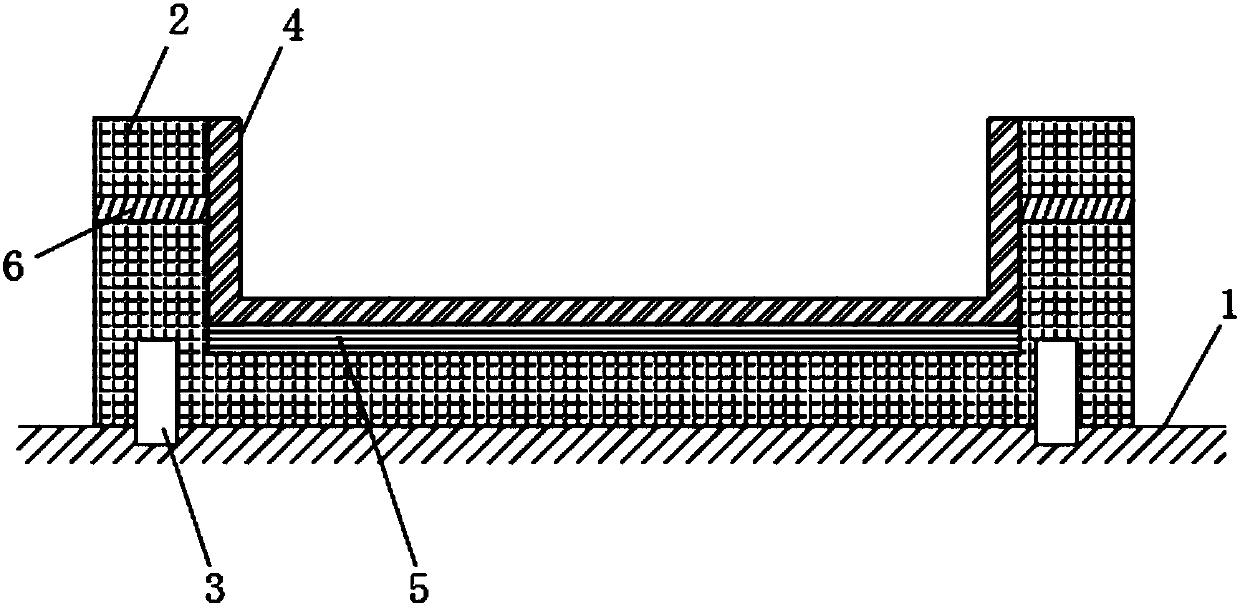

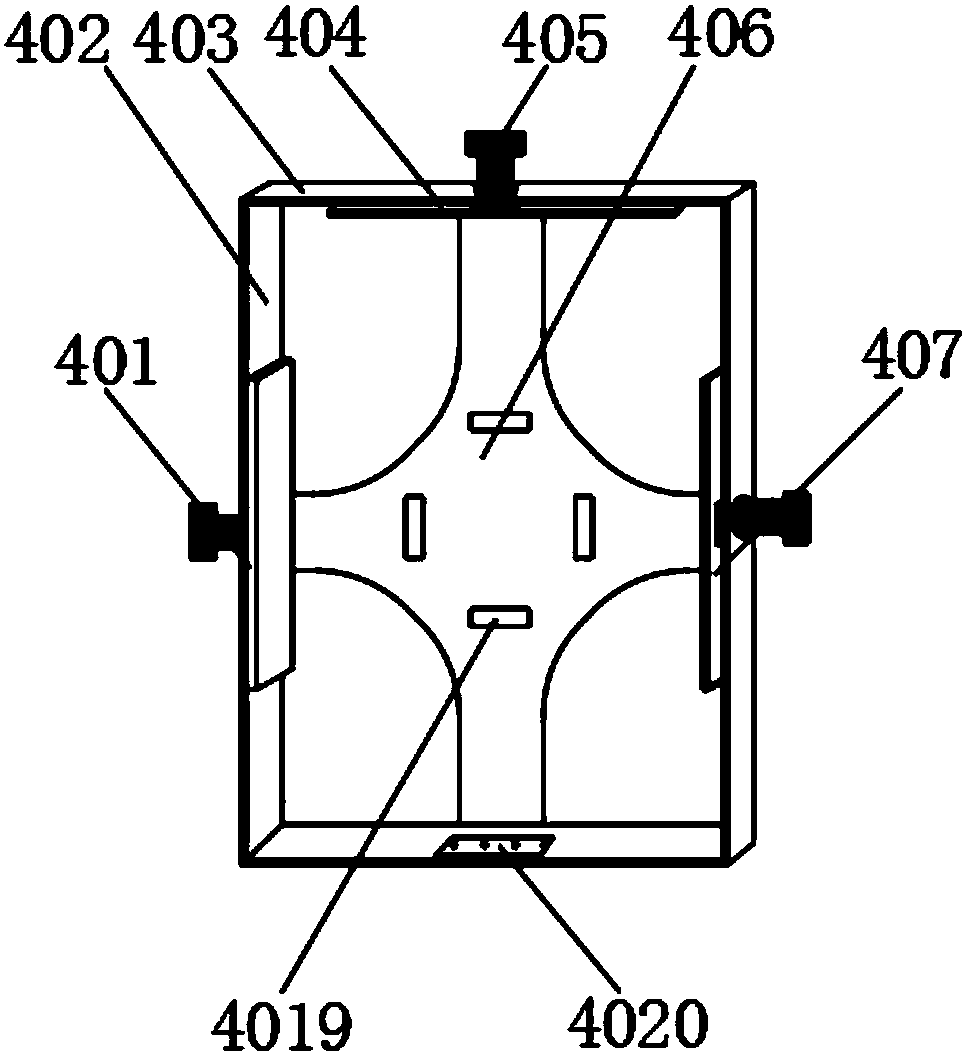

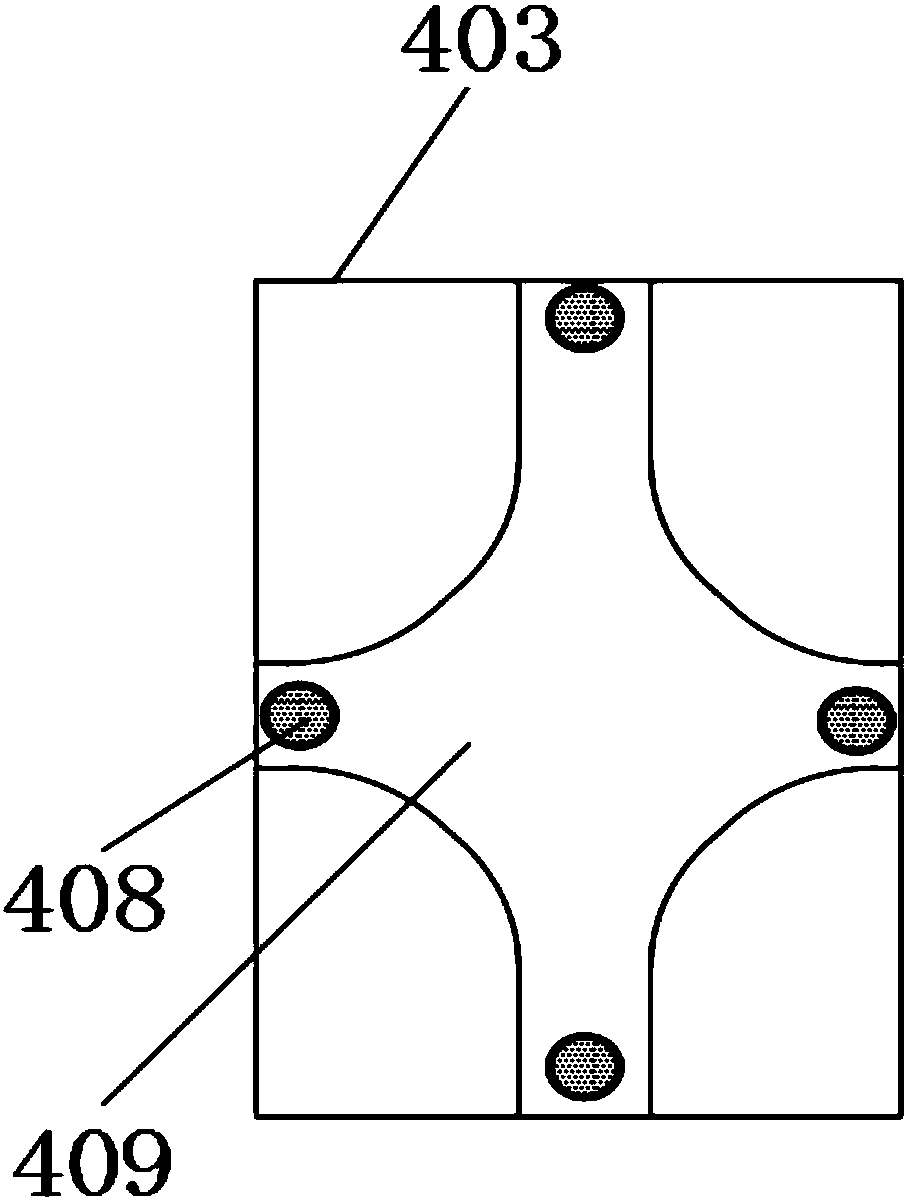

[0027] Example: such as Figure 1-6 As shown, the present invention provides a metal mobile phone case processing equipment, including a working platform 1, the top of the working platform 1 is provided with a mobile phone case outer fixture 2, and the working platform 1 and the mobile phone case outer fixture 2 are fixed by a fixing member 3 Connection, the inner side of the mobile phone case outer fixture 2 is provided with a mobile phone case inner fixture 4, and the connection between the bottom side of the mobile phone case inner fixture 4 and the mobile phone case outer fixture 2 is provided with an extrusion protection pad 5, and the mobile phone case outer fixture The upper part of the tool 2 is provided with a fastening bolt hole 6, and the fixture 404 in the mobile phone shell includes a left regulator 401, an inner wall 402, a body 403, an upper regulator 404, an adjusting screw hole 405, a bottom plate 406, a right regulator 407, a fixed Suction cup 408, floor back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com