Special tool for surface grinder for machining demagnetized micro-dimension part

A surface grinder and micro-sized technology, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding workpiece planes. It can solve the difficulty in positioning small-sized thin-walled workpieces, the non-magnetic materials cannot be used, and the surface is easily damaged. and other problems, to achieve the effect of improving processing efficiency and processing quality, broadening the scope of processing, and overcoming difficulties in garment clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

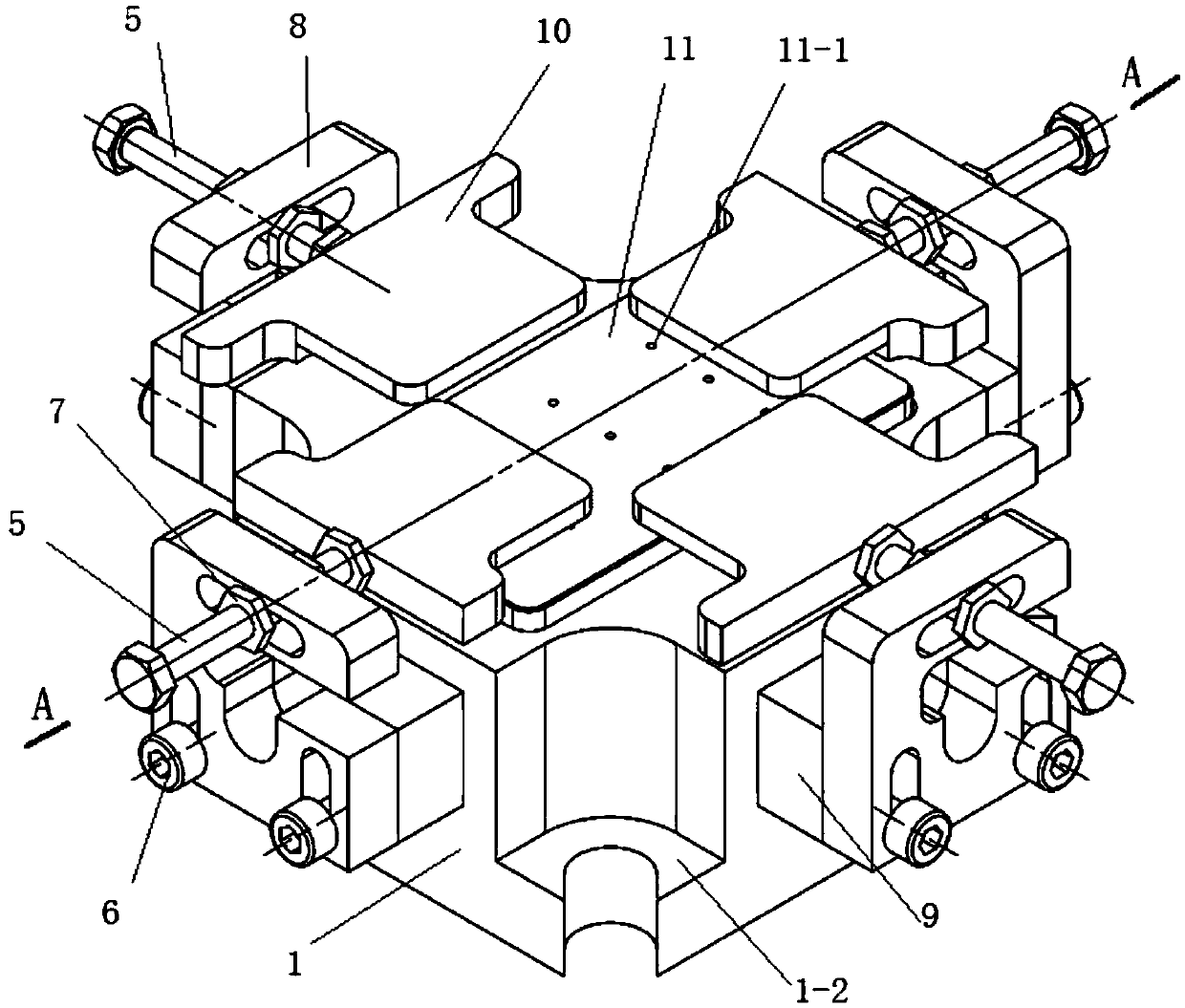

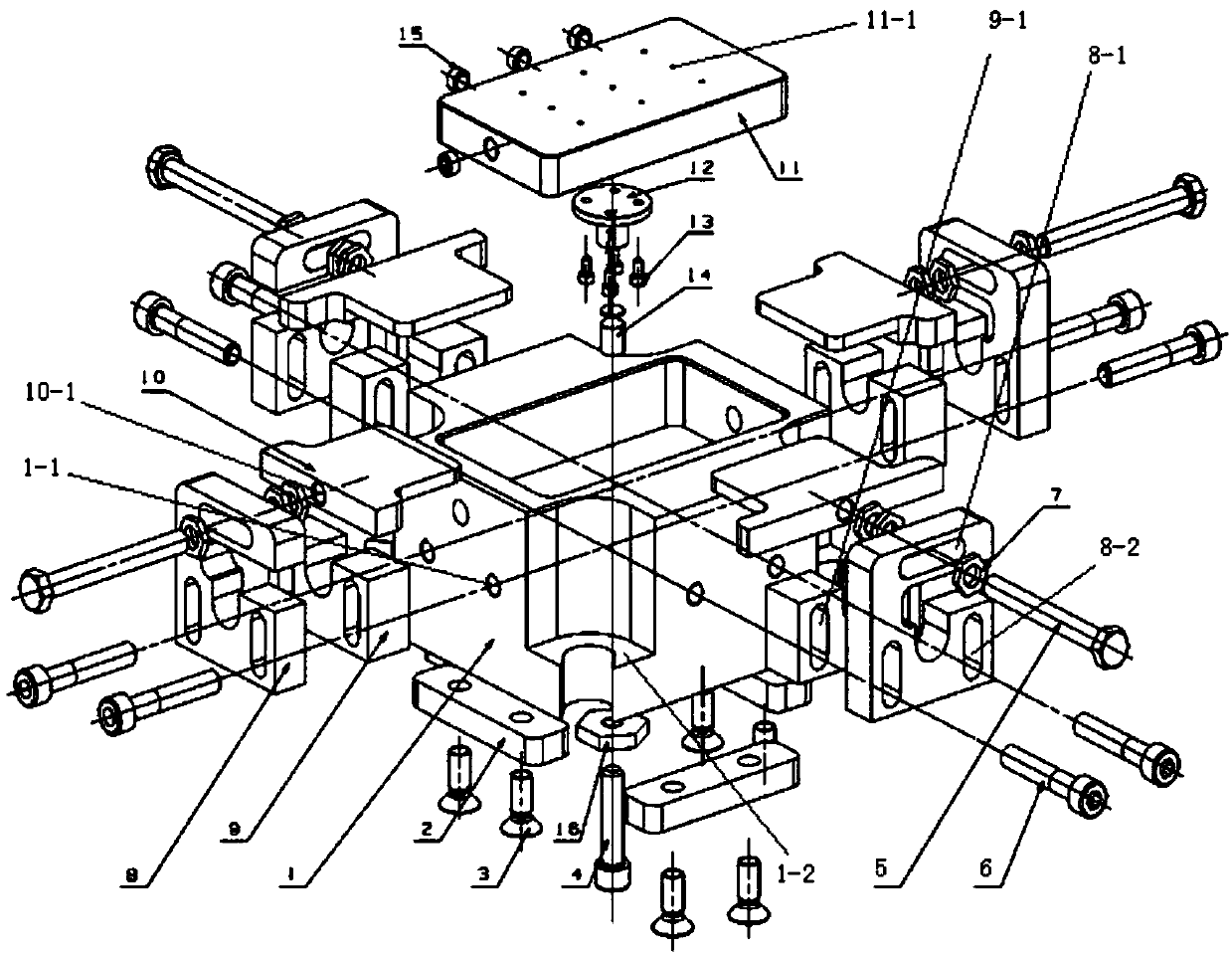

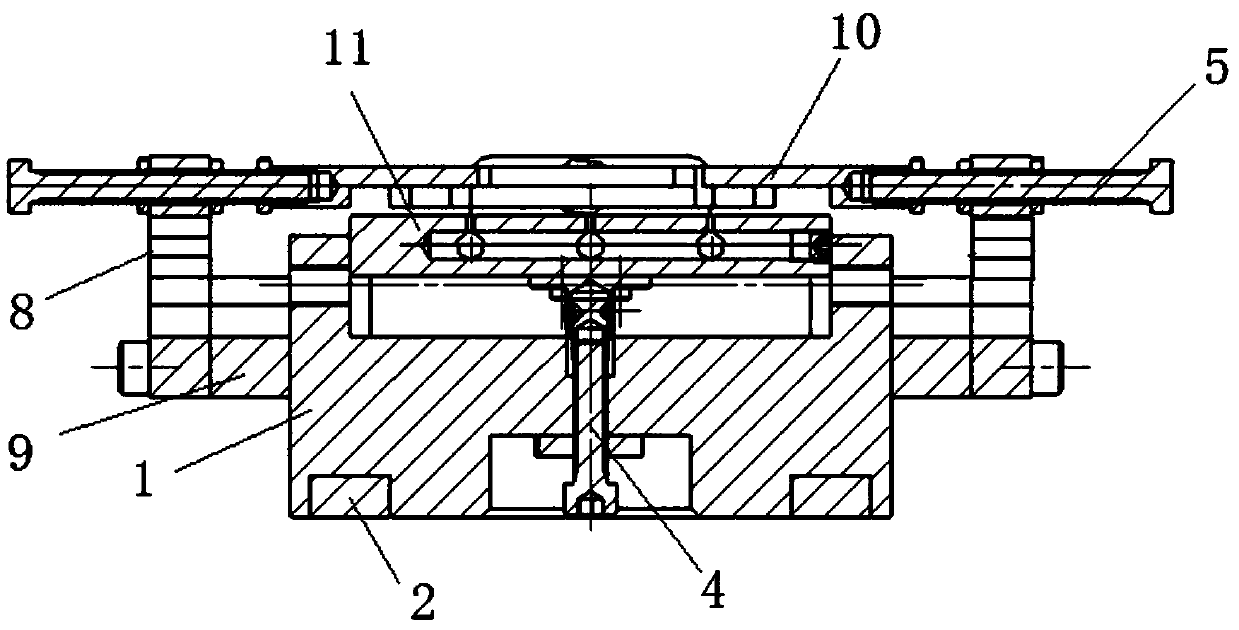

[0015] Such as figure 1 , figure 2 , image 3 The shown special tooling for surface grinders for processing demagnetized micro-sized parts includes an adjustable base body, four sets of displacement systems symmetrically installed around the adjustable base body, and an external negative pressure system.

[0016] The adjustable base body includes a trough-shaped base 1 with a rectangular inner groove and a rectangular adsorption platform 11 that can be raised and lowered along the inner groove of the base. The lifting movement of the platform is stable and unimpeded. The rectangular adsorption platform is a hollow porous structure with an inner cavity and evenly distributed adsorption holes 11-1 on the top plate, and a negative pressure adsorption port equipped with a trachea joint 15 is installed on one side or both sides of the rectangular adsorption platform. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com