Preparation method of foamed brick mixed slurry

A technology for mixing slurry and production methods, applied in chemical instruments and methods, clay preparation devices, cement mixing devices, etc., can solve the problems of polluting the working environment, large dust, etc., and achieve the effect of avoiding the spread of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below through specific implementations:

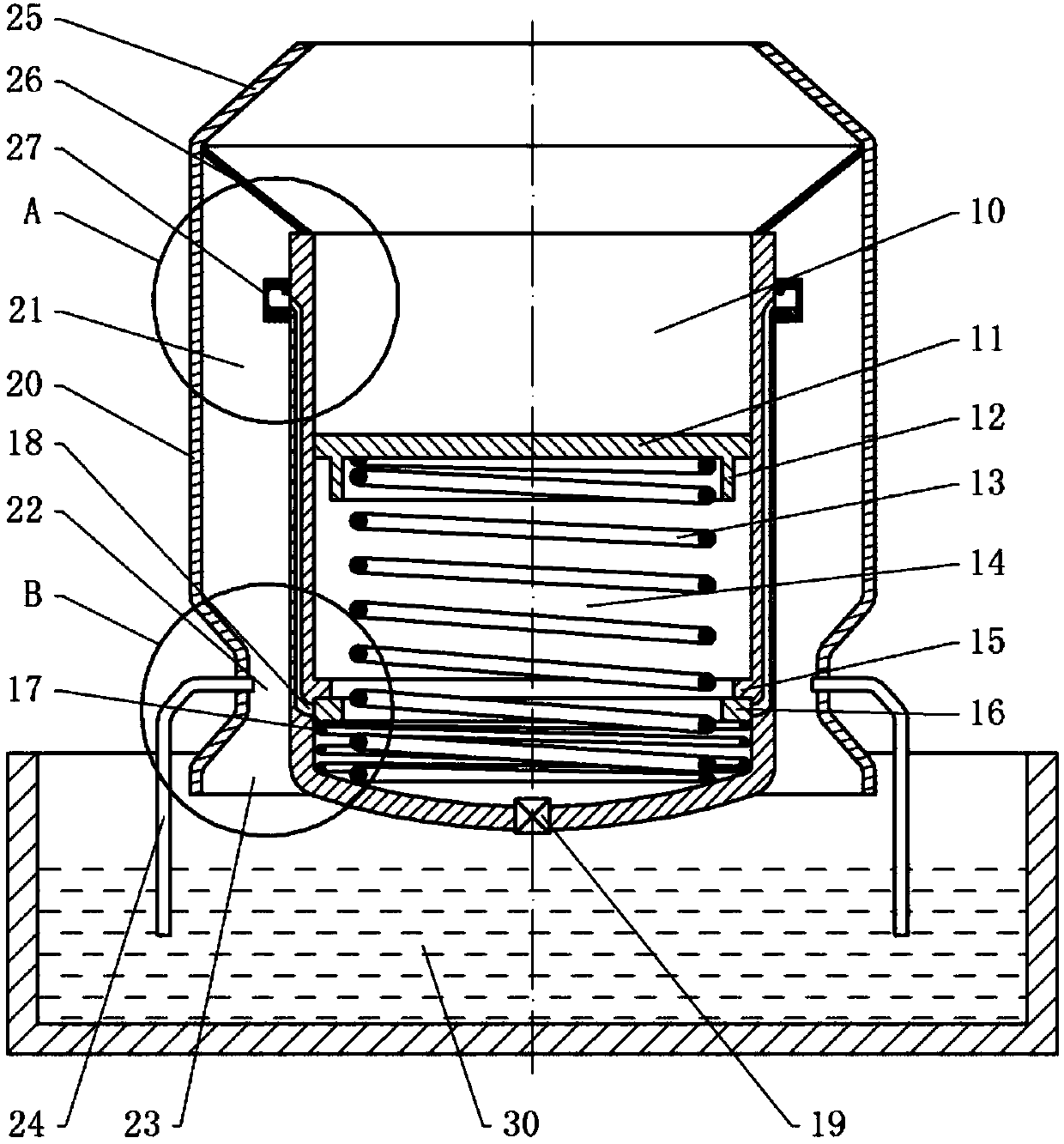

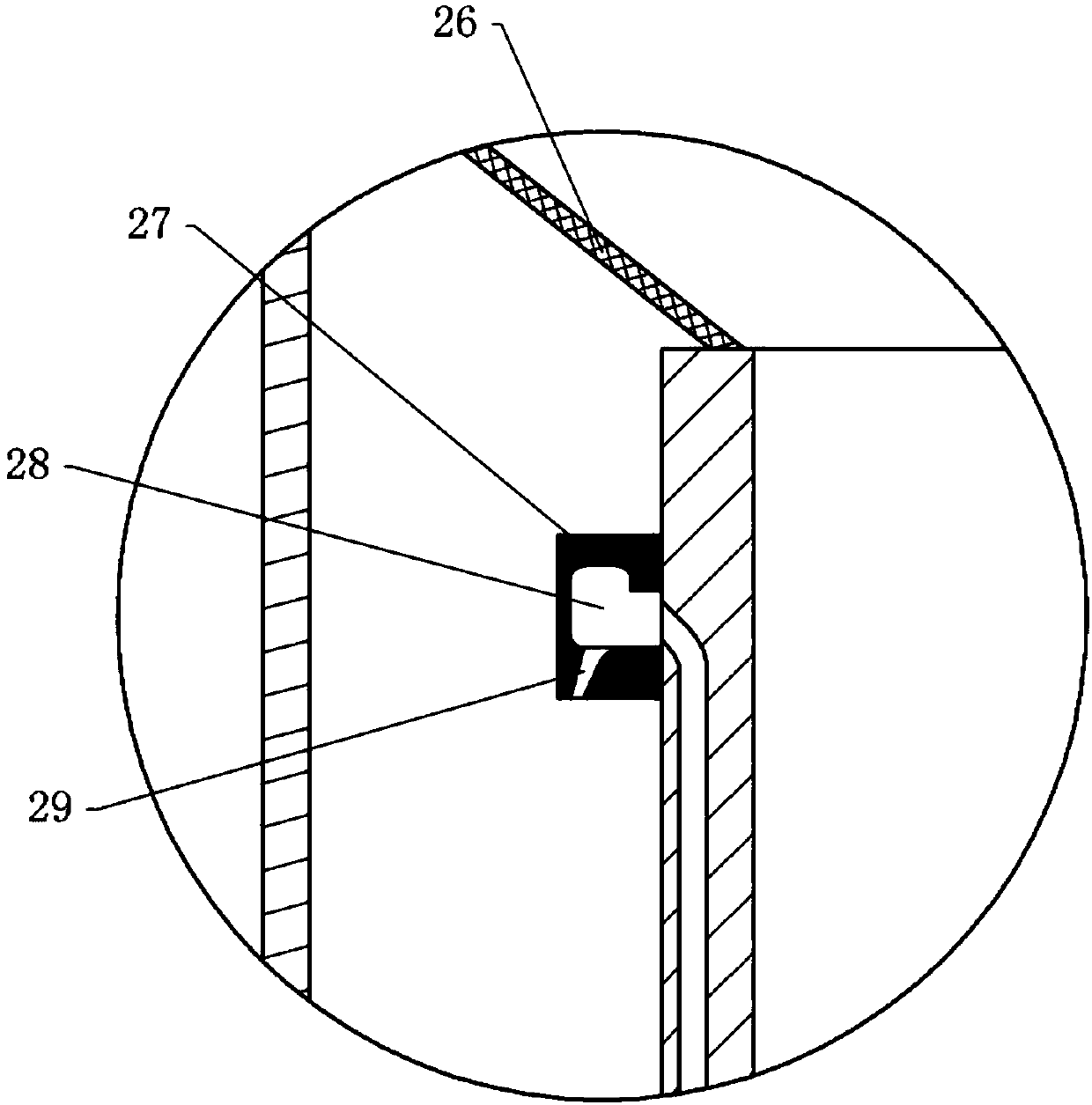

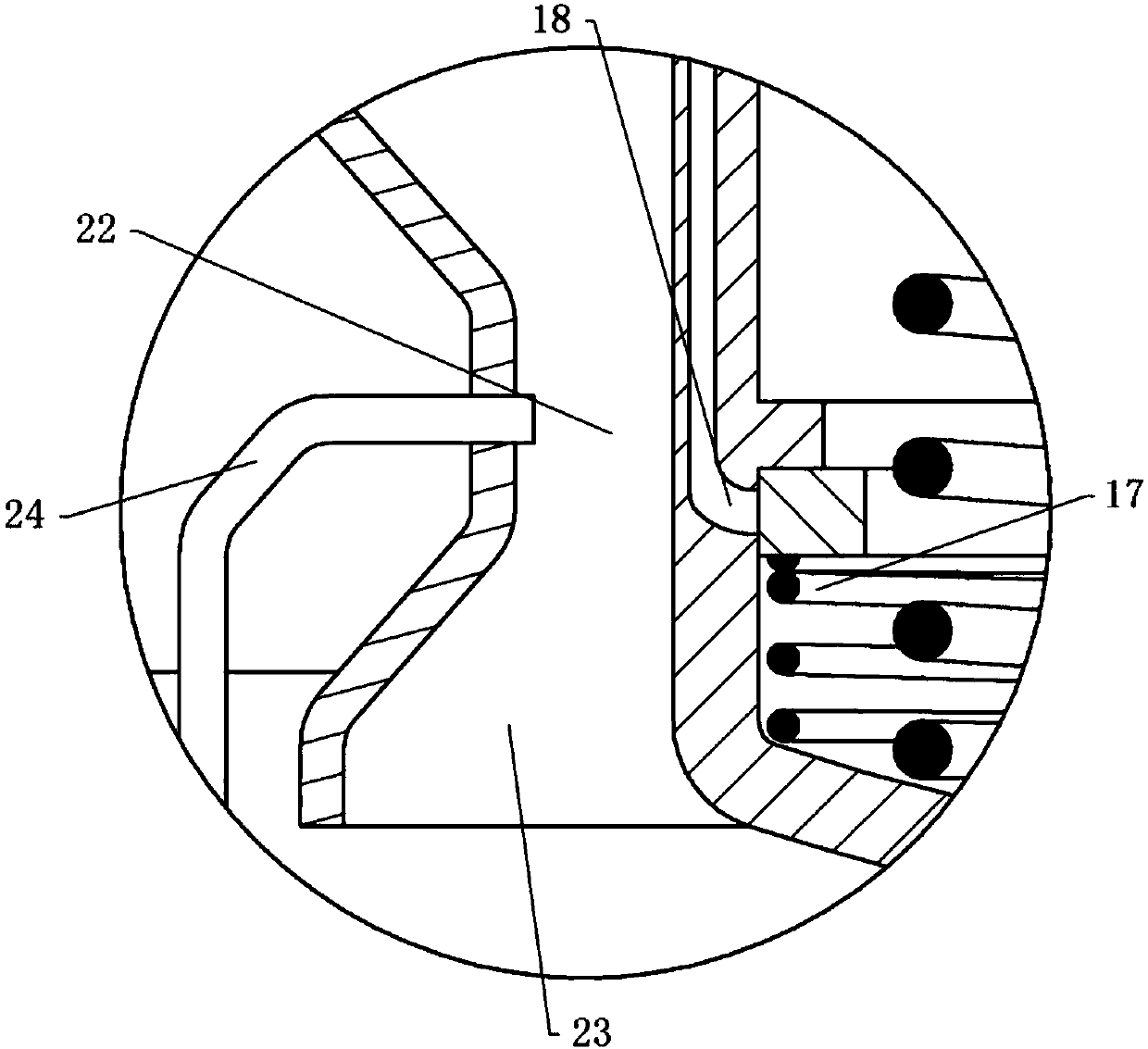

[0029] The reference signs in the drawings of the specification include: mixing drum 10, partition 11, extrusion rib 12, return spring 13, high pressure chamber 14, limit rib 15, sealing ring 16, first spring 17, exhaust hole 18 , One-way valve 19, dust suction tube 20, air intake section 21, throat 23, water suction pipe 24, air guide tube 25, wire mesh 26, air jet ring 27, air cavity 28, jet wedge 29, water tank 30.

[0030] The manufacturing method of the foamed brick mixed slurry of this embodiment uses a raw material stirring device to stir the raw materials. Such as figure 1 , figure 2 with image 3 As shown, the raw material mixing device includes a mixing drum 10, a dust removal drum and a water tank 30; the mixing drum 10, the dust removal drum and the water tank 30 are all fixed on the frame, and the dust removal drum is sleeved outside the mixing drum 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com