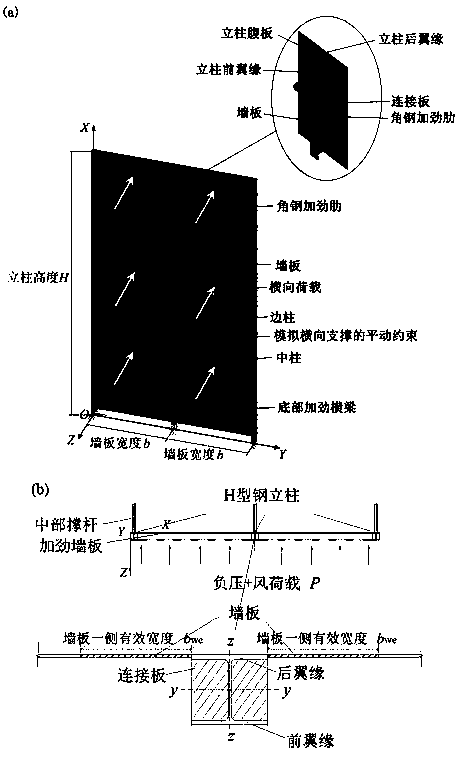

Calculating method for bending strength of dust-collector-box standing column under transverse-load effect

A technology of lateral load and flexural strength, applied in the field of structure, can solve the problems of not considering the cooperative work of the wall panel and the column, the force carrier is not accurate enough, and the force transmission mechanism is not accurate enough, so as to achieve convenient and accurate calculation of the flexural strength of the section, The calculation method is accurate and reliable, and the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

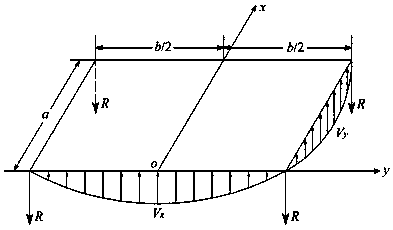

Method used

Image

Examples

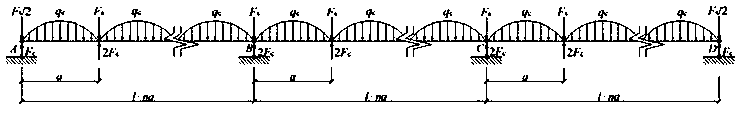

Embodiment 1

[0089] The column of the dust collector box is a two-span column; the number n of wall panels between each column is 1; the spacing a of the stiffeners on the wall panels is 600mm, and the width b of one-span wall panels is 600mm, that is, b / a= 1; Column span l=n×a=600mm; the value p of lateral uniform load such as negative pressure and wind load is 0.008N / mm 2 . The maximum bending moment M of the section of the middle column calculated by programming with MATLAB language t As shown in Table 1, calculate M with the above method t The value has nothing to do with the column section size.

Embodiment 2~ Embodiment 54

[0091] Embodiment 2~embodiment 54 only changes the number n of the wall panel divisions n between each span of the column and the width b of a span wall panel with respect to Embodiment 1, and then changes the size of b / a, the specific construction parameters and the use of MATLAB language The maximum bending moment M of the intermediate column section calculated by programming t As shown in Table 1.

Embodiment 55

[0093] The column of the dust collector box is a two-span column; the number n of wall panels between each column is 1; the spacing a of the stiffeners on the wall panels is 1000mm, and the width b of one-span wall panels is 1000mm, that is, b / a= 1; column span l=n×a=1000mm; the value p of lateral uniform load such as negative pressure and wind load is 0.009N / mm 2 . The maximum bending moment M of the section of the middle column calculated by programming with MATLAB language t As shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com