Optical total reflection film used for photovoltaic module

A total reflection film, photovoltaic module technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problem of low utilization efficiency, and achieve the effect of improving utilization efficiency, improving a grade, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

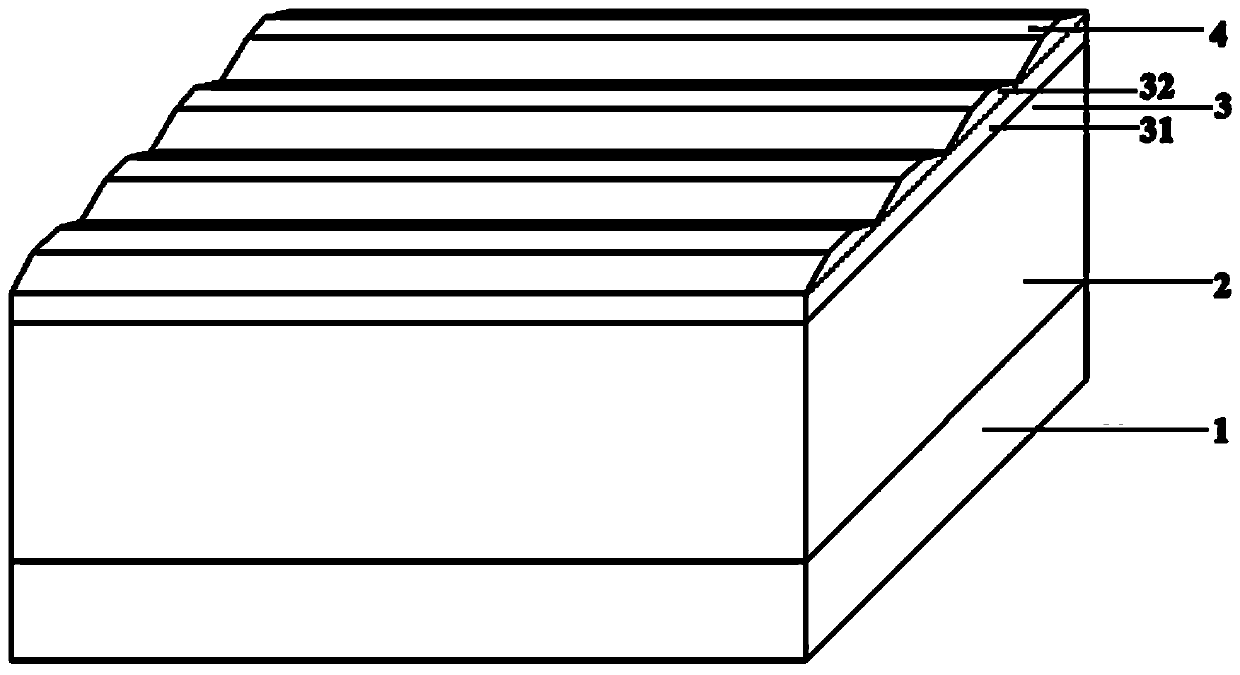

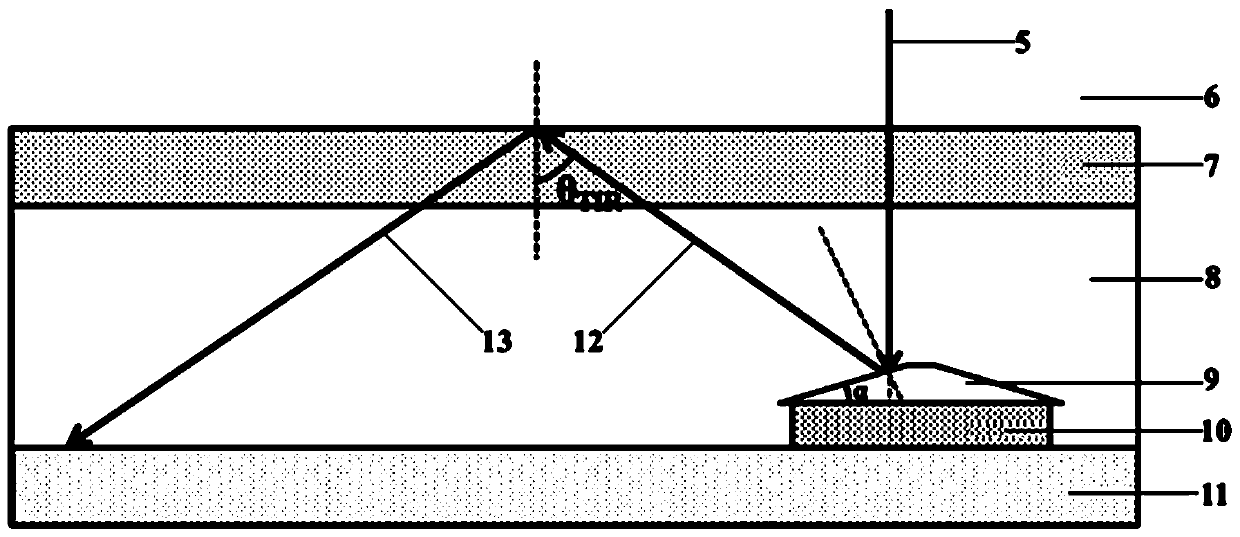

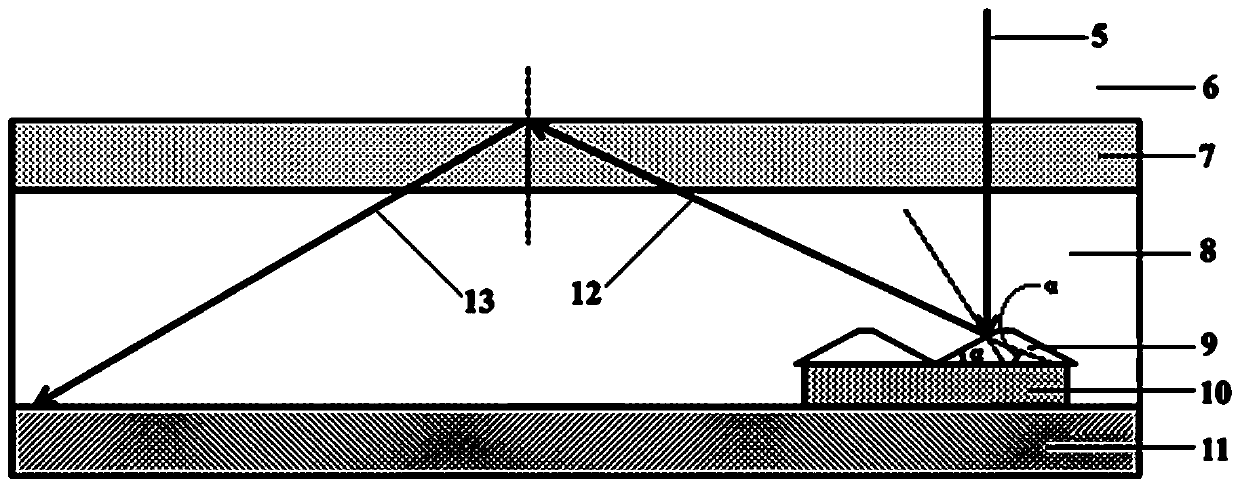

[0030] A light total reflection film 9 for a photovoltaic module, the structure is as attached figure 1 As shown, it includes an adhesive layer 1 , a base layer 2 , a structural layer 3 (including a base 31 and a microstructure 32 ) and a reflective layer 4 . The adhesive layer 1 is located at the bottom, the base layer 2 is located above the adhesive layer 1 , the structural layer 3 is located above the base layer, and the top of the structural layer 3 is provided with a reflective layer 4 . The structural layer 3 includes a base 31 and a microstructure 32 . The microstructure 32 is composed of a plurality of parallel horizontal regular quadrangular prisms. The section of the regular quadrangular prisms is isosceles trapezoidal.

[0031] Wherein the thickness of bonding layer 1 is 10um, and the thickness of base layer 2 is 70um, preferably the short side length of the isosceles trapezoid of microstructure 32 in structure layer 3 is 1um, can deposit reflective layer 4 (alumin...

Embodiment 2

[0034] A light total reflection film 9 for a photovoltaic module, the structure is as attached figure 1 As shown, it includes an adhesive layer 1 , a base layer 2 , a structural layer 3 (including a base 31 and a microstructure 32 ) and a reflective layer 4 . An adhesive layer 1 is located at the bottom, a base layer 2 is located above the adhesive layer 1 , a structural layer 3 is located above the base layer, and the top contains a reflective layer 4 . The structural layer 3 includes a base 31 and a microstructure 32 . The microstructure 32 is composed of a plurality of parallel horizontal regular quadrangular prisms. The section of the regular quadrangular prisms is isosceles trapezoidal.

[0035] Wherein the thickness of the bonding layer 1 is 10um, and the thickness of the base layer 2 is 70um. As preferably, the short side length of the isosceles trapezoid of the microstructure 32 in the structural layer 3 is 1um, so that the reflective layer 4 (aluminized) can be depos...

Embodiment 3

[0038] A light total reflection film for photovoltaic modules. Considering the error in the production of microstructures in actual production, the optimal choice of bottom angle is 25°. Considering the problem that the protruding part of the mold is worn for a long time during the production process, which leads to the increase of the bottom angle of the microstructure, when the bottom angle is still less than 30°, the slight wear of the mold will not affect the total light reflection of the photovoltaic module The reflective effect of the film can prolong the service life and reduce the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com