Fiber for tire, rubber/fiber complex, and tire

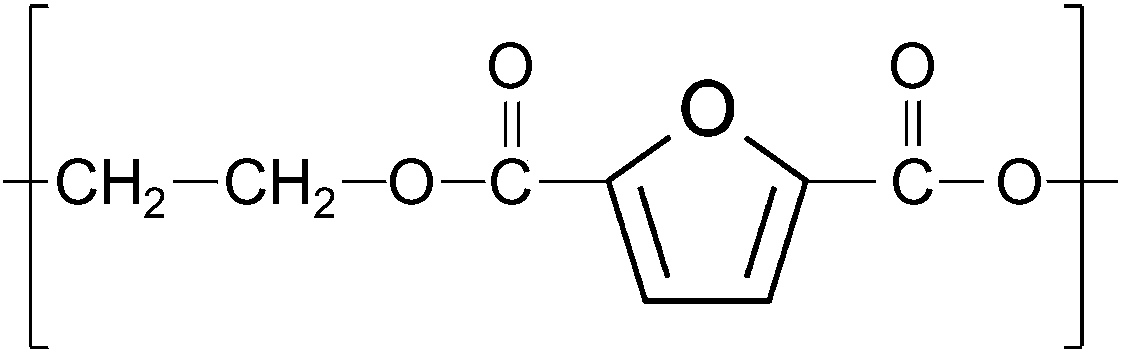

A fiber and tire technology, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as high environmental burden and achieve good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

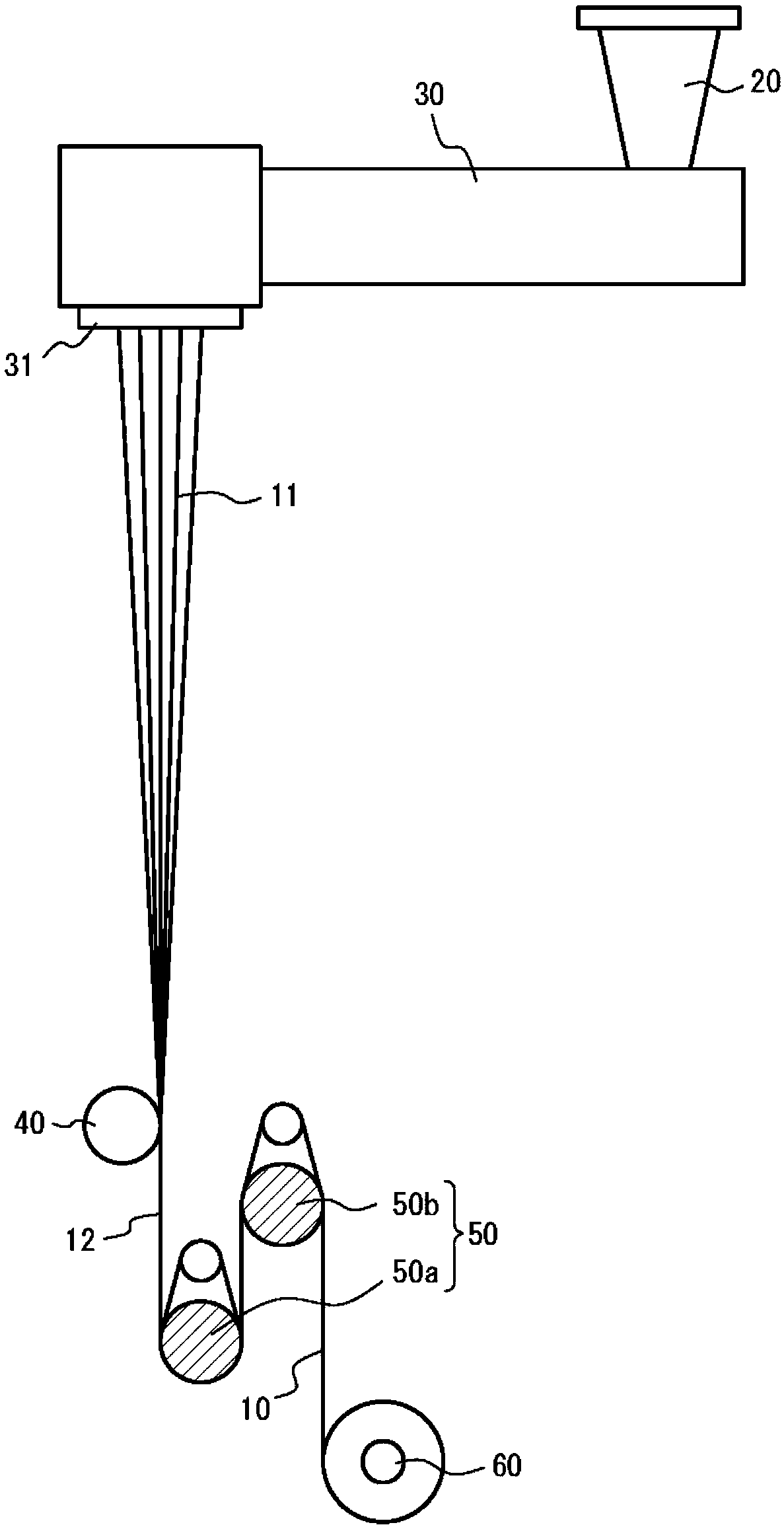

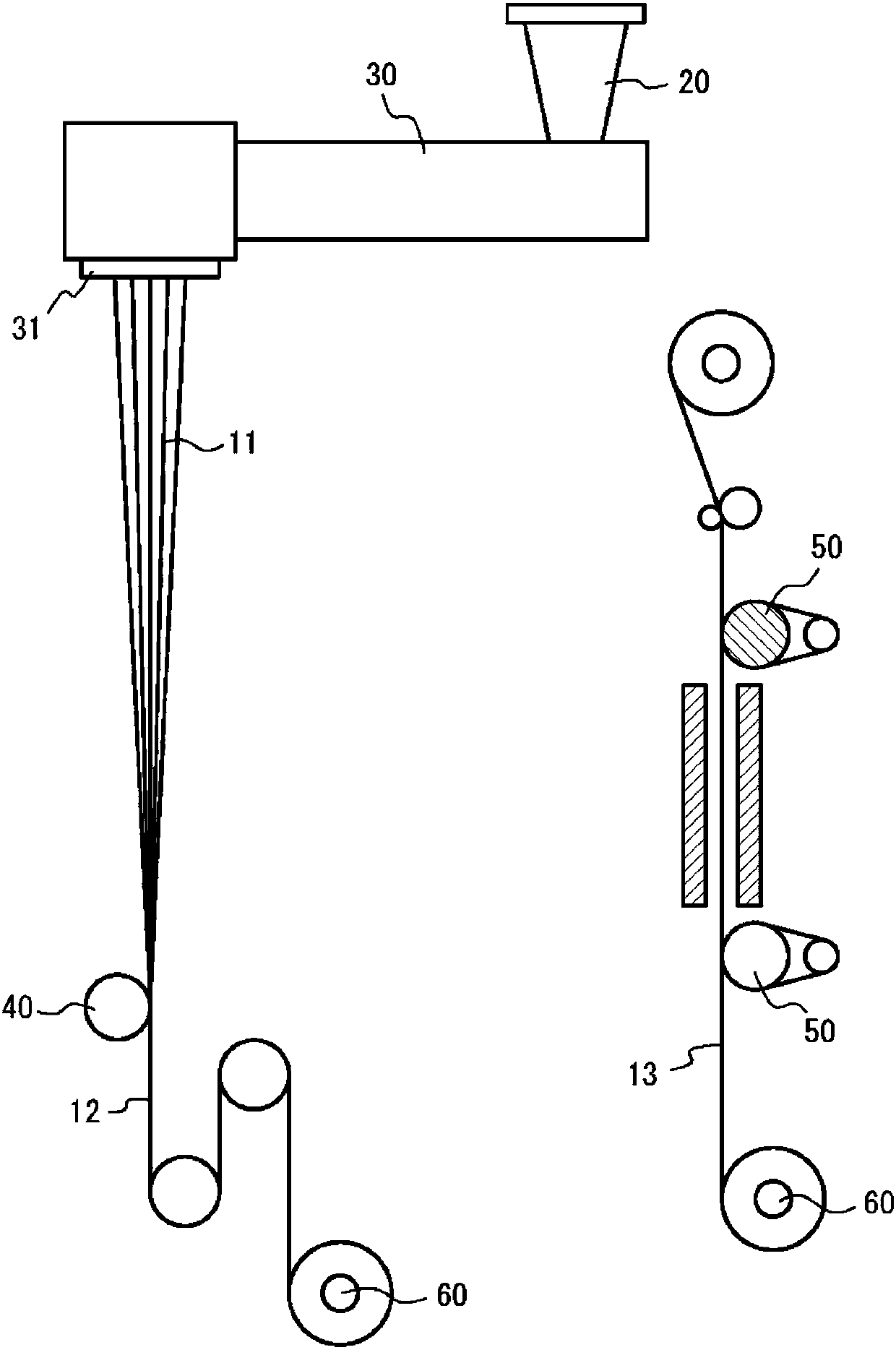

Method used

Image

Examples

Embodiment 1

[0126] A PEF composition consisting only of 100% bio-based PEF having a Mw of 75,600 and an intrinsic viscosity of 0.76 dl / g was melt spun by passing it through a 96-hole die at an extrusion temperature of 275°C and the resulting 96 The filaments are bundled into an undrawn yarn, and the undrawn yarn is continuously drawn without recycling, and then taken up to obtain PEF raw material with a fineness of 1,100 dtex (11.5 dtex per filament) yarn. The spinning draw and draw ratio are shown in Table 1 and the time from the completion of extrusion of the filament in the spinning step to the start of drawing of the undrawn yarn was 10 seconds or less.

[0127] The initial twist and final twist of the two PEF raw yarns thus obtained were twisted together at a twist of 47 turns per 10 cm length, thereby producing a fiber having a fineness of 1,100 dtex / 2, a twist of 47×47 (turns / 10cm) and Fiber for tires with a fiber count of 60 / 5 cm.

Embodiment 2~4 and comparative example 1

[0129] Fibers for tires were obtained in the same manner as in Example 1 except that the spinning draw and draw ratio were changed.

Embodiment 5

[0131] Fibers for tires were obtained in the same manner as in Example 1 except that 100% bio-based PEF having an intrinsic viscosity of 1.10 dl / g was used and the extrusion temperature was set at 310°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com