Devices for warning of pre-fire conditions caused by localized overheating of electrical equipment

A technology of local overheating and electrical equipment, which is applied to fire alarms with electric action, fire alarms with hydraulic/pneumatic action, fire alarms, etc., and can solve problems such as slow heating gas discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

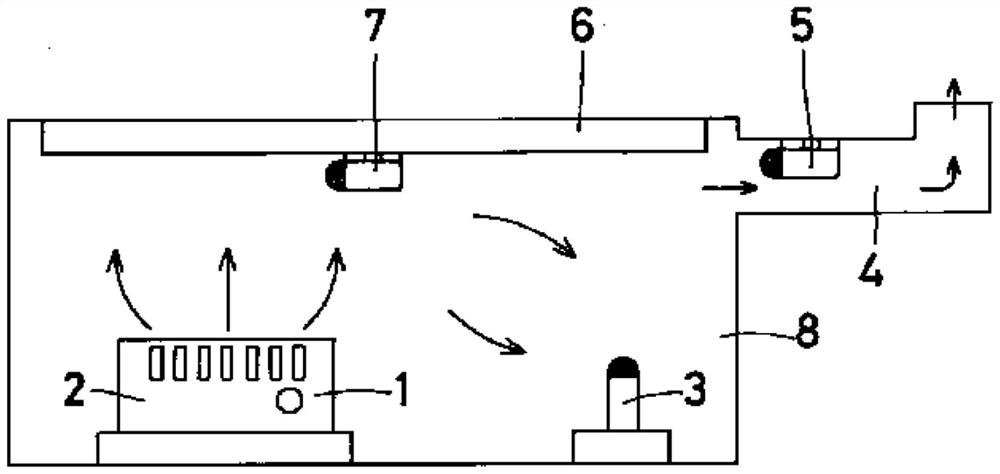

[0055] The technical aim of the present invention is to create an automatic tool for early pre-ignition condition alerting of fires caused by local overheating of electrical equipment, when the heating of wires or electrical contacts exceeds the allowable operating parameters (>100°C), but has not yet reached At levels that are flammable (>250°C), pyrolysis of the material occurs at this level.

[0056] The technical result of the claimed solution is to increase the likelihood of early detection of pre-fire conditions.

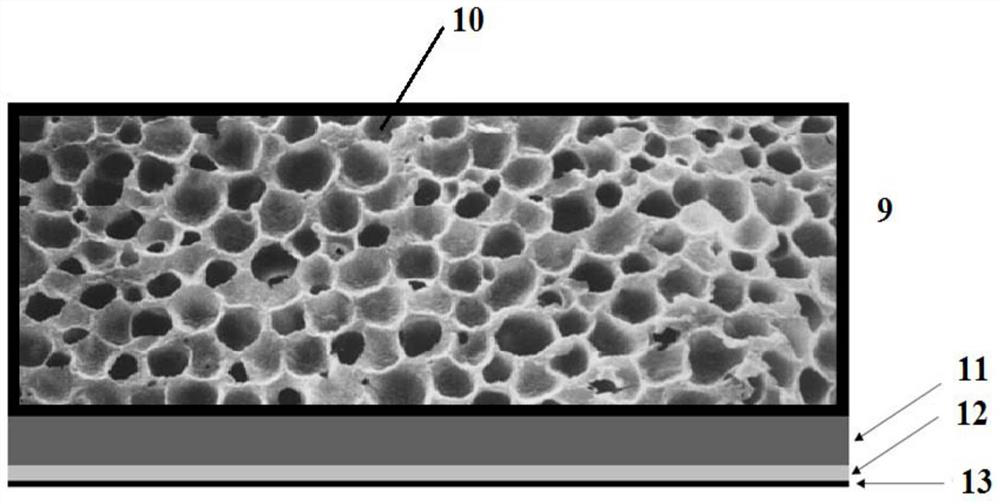

[0057] The provided device is made of a polymer thermoset composite with an explosion failure temperature in the range of 80-200°C, the continuous phase of which is formed by a thermoset polymer containing odorants such as sulphur dioxide, low molecular weight mercaptans, bisulfites Alkyl sulfides, dialkyl disulfides, or combinations thereof.

[0058] A feature of the described polymer composites is the use of thermosetting polymers as polymeric materials. U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com