Die, method for manufacturing organic light-emitting diode, and organic light-emitting diode

A mold and electrode technology, applied in the field of organic light-emitting diodes, can solve the problem of unusable organic semiconductor layers and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, each configuration will be described using the drawings. In the drawings used in the following description, the characteristic parts may be enlarged for convenience to understand the characteristics, and the dimensional ratio of each component may not necessarily be the same as the actual situation. Materials, dimensions, and the like illustrated in the following description are examples, and the present invention is not limited to such materials and dimensions, and can be appropriately changed and implemented within a range that does not change the gist.

[0051] "mold"

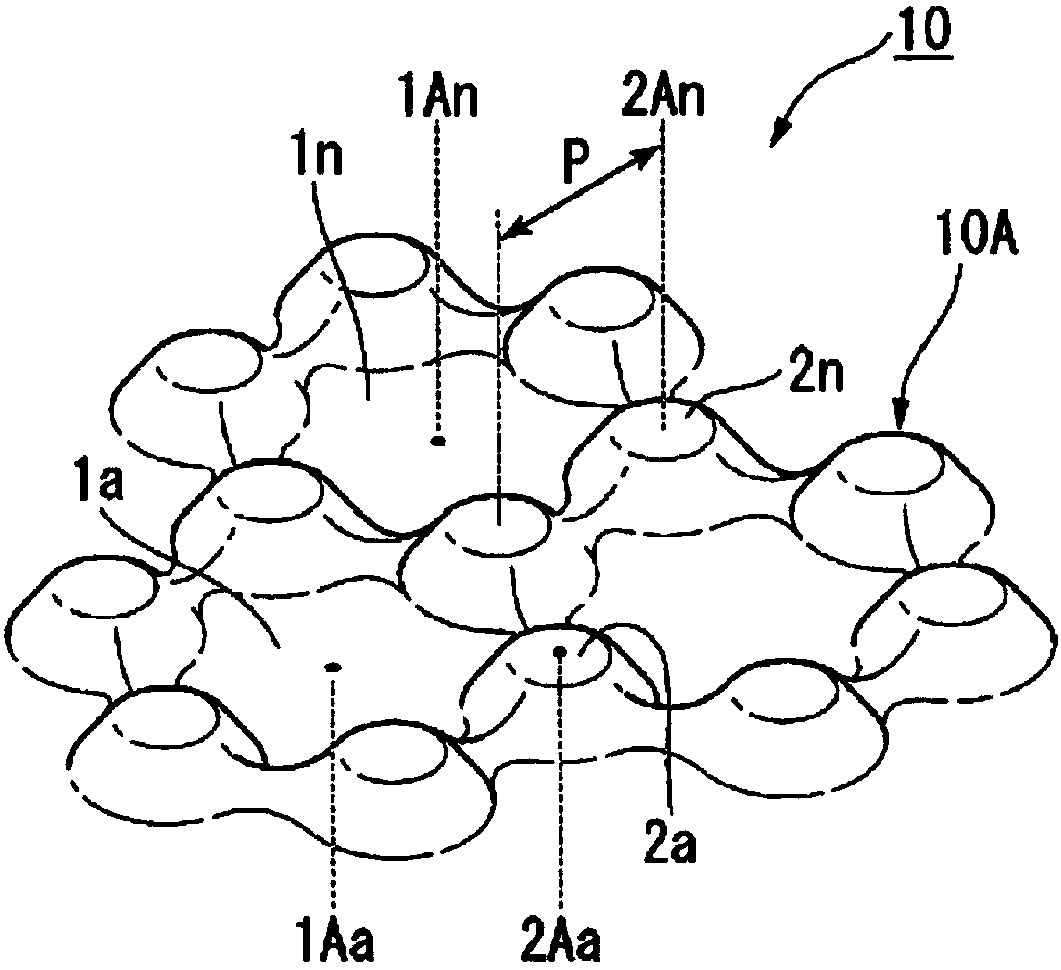

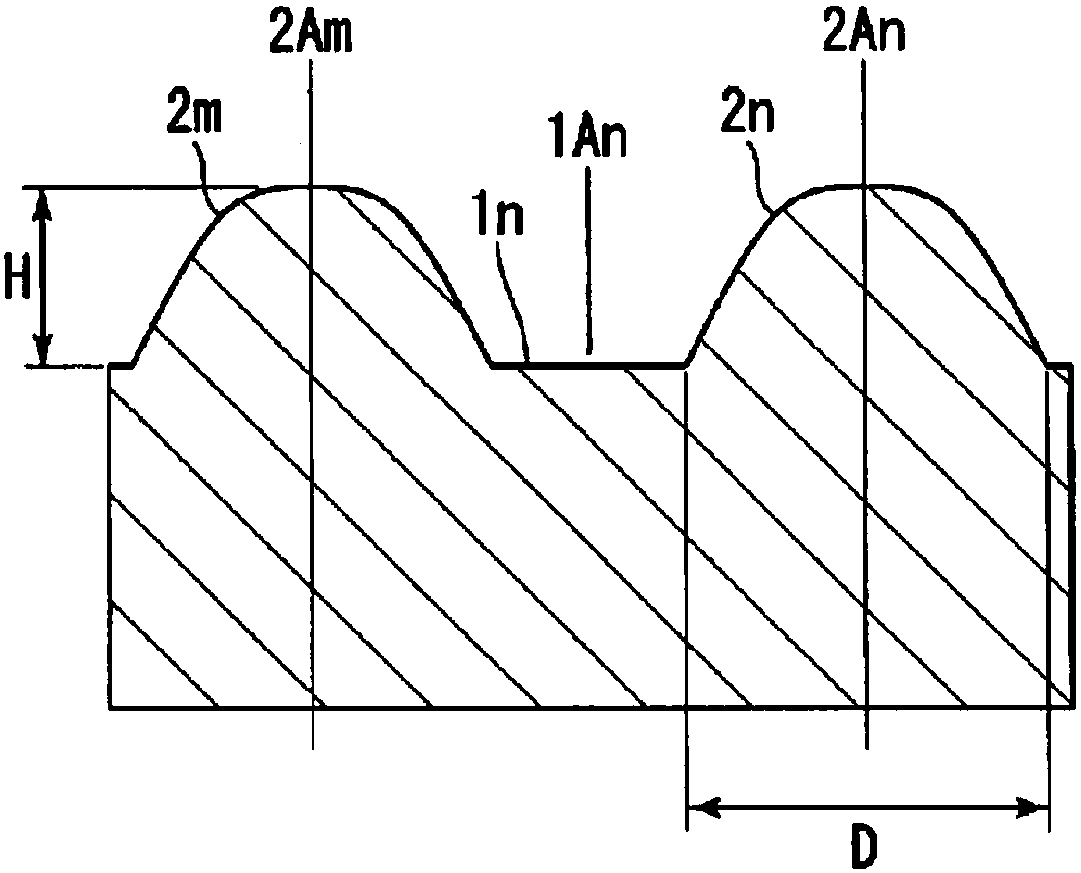

[0052] figure 1 It is a perspective view which schematically shows the mold of one aspect of this invention. In the mold 10 according to one aspect of the present invention, a plurality of flat surfaces 1 a to 1 n and a plurality of convex portions 2 a to 2 n are provided on the main surface 10A. The plurality of flat surfaces 1 a to 1 n are arranged in a region surrounded by the most ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com