Micron-scale multiphase fluid atomization mixing device

A technology of multiphase fluid and mixing device, which is applied in the fields of mining, agriculture, animal husbandry, and chemical industry. Maintenance and reuse, simple and easy connection, the effect of shortening the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

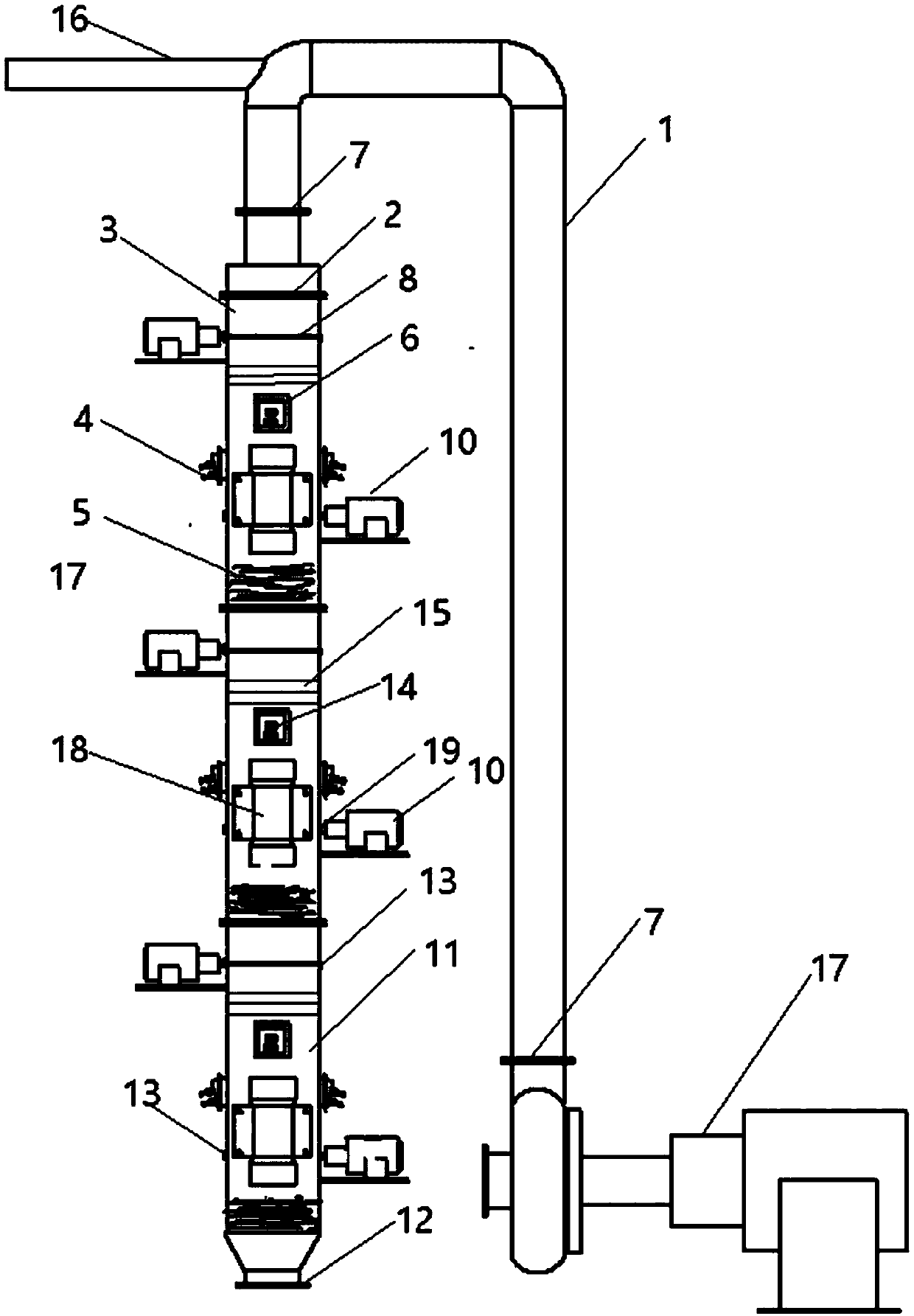

[0041] Such as figure 1 A micron-scale atomized multiphase fluid mixing device shown includes a feed part, a cylinder part 3 and a discharge part 11, the feed part is connected to the upper end of the cylinder part 3 through the feed flange 7, and the cylinder The lower end of part 3 is connected with discharge part 11 by discharge flange 12 (as figure 2 Shown); inside the barrel part 3, a plurality of fluid mixing units are distributed from top to bottom, and the fluid mixing unit includes an atomizing nozzle mechanism, a stirring mechanism 19, a medium filling group and a dispersing sieve plate mechanism arranged from top to bottom. There are two groups of atomizing nozzle mechanisms, which are symmetrically arranged on the side wall of the cylinder part 3. The two groups of atomizing noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com