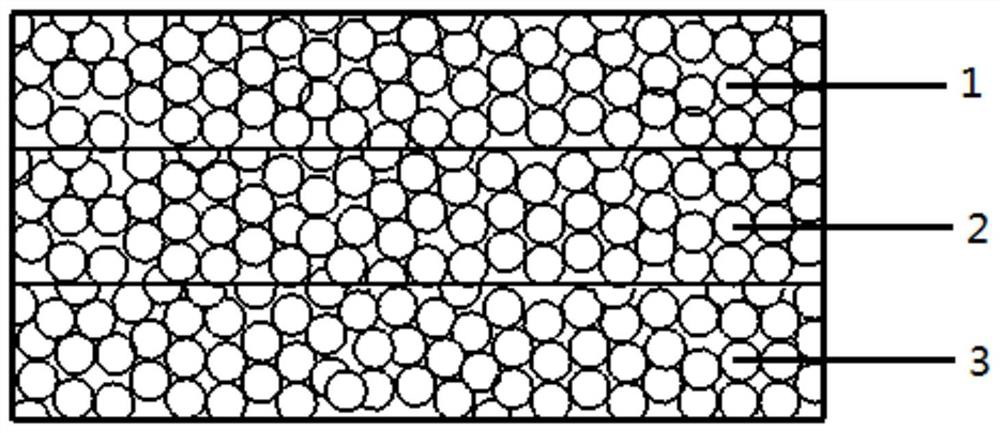

A thermoplastic polyurethane foam product with different gradient densities and its molding process

A technology of thermoplastic polyurethane and foamed products, which is applied in the field of material processing, can solve the problem of single function of foam materials, and achieve the effects of environmentally friendly molding methods, pollution-free molding methods, and simple molding methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 5703TPU into the autoclave and feed CO 2 , the pressure of the high-pressure reactor is 12Mpa, the temperature is 40°C, and the pressure is maintained for 3 hours. After the pressure is released, it is quickly put into the foaming equipment, heated and foamed at 110°C for 4 minutes, and the density is 0.38g / cm3. 3 foamed particles;

[0027] Put 5703TPU into the autoclave and feed CO 2 , the pressure of the high-pressure reactor is 15Mpa, the temperature is 45°C, and the pressure is maintained for 3 hours. After the pressure is released, it is quickly put into the foaming equipment, heated and foamed at 115°C for 6 minutes, and the density is 0.33g / cm 3 foamed particles;

[0028] Put 5703TPU into the autoclave and feed CO 2 , the pressure of the high-pressure reactor is 20Mpa, the temperature is 45°C, and the pressure is maintained for 4 hours. After the pressure is released, it is quickly put into the foaming equipment, heated and foamed at 120°C for 8 minutes, a...

Embodiment 2

[0032] Put 5703TPU into the autoclave and feed CO 2, the pressure of the high-pressure reactor is 12Mpa, the temperature is 40°C, and the pressure is maintained for 3 hours. After the pressure is released, it is quickly put into the foaming equipment, heated and foamed at 110°C for 4 minutes, and the density is 0.38g / cm3. 3 foamed particles;

[0033] Put 5703TPU into the autoclave and feed CO 2 , the pressure of the high-pressure reactor is 15Mpa, the temperature is 45°C, and the pressure is maintained for 3.5 hours. After the pressure is released, it is quickly put into the foaming equipment, and heated and foamed at 115°C for 7 minutes to obtain a density of 0.31g / cm 3 foamed particles;

[0034] Put 5703TPU into the autoclave and feed CO 2 , the pressure of the high-pressure reactor is 20Mpa, the temperature is 45°C, and the pressure is maintained for 4 hours. After the pressure is released, it is quickly put into the foaming equipment, heated and foamed at 120°C for 8 mi...

Embodiment 3

[0037] Put 5703TPU into the autoclave and feed CO 2 , the pressure of the high-pressure reactor is 12Mpa, the temperature is 40°C, and the pressure is maintained for 3 hours. After the pressure is released, it is quickly put into the foaming equipment, heated and foamed at 110°C for 4 minutes, and the density is 0.38g / cm3. 3 foamed particles;

[0038] Put 5703TPU into the autoclave and feed CO 2 , the pressure of the high-pressure reactor is 14Mpa, the temperature is 45°C, and the pressure is maintained for 3 hours. After the pressure is released, it is quickly put into the foaming equipment, heated and foamed at 115°C for 5 minutes, and the density is 0.35g / cm 3 foamed particles;

[0039] Put 5703TPU into the autoclave and feed CO 2 , the pressure of the high-pressure reactor is 15Mpa, the temperature is 45°C, and the pressure is maintained for 3.5 hours. After the pressure is released, it is quickly put into the foaming equipment, and heated and foamed at 115°C for 7 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com