Printing and dyeing wastewater denitrifying technology

A technology for printing and dyeing wastewater and denitrification, which is used in aerobic and anaerobic process treatment, water pollutants, water/sludge/sewage treatment, etc., and can solve the problems of large flow, high construction cost and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

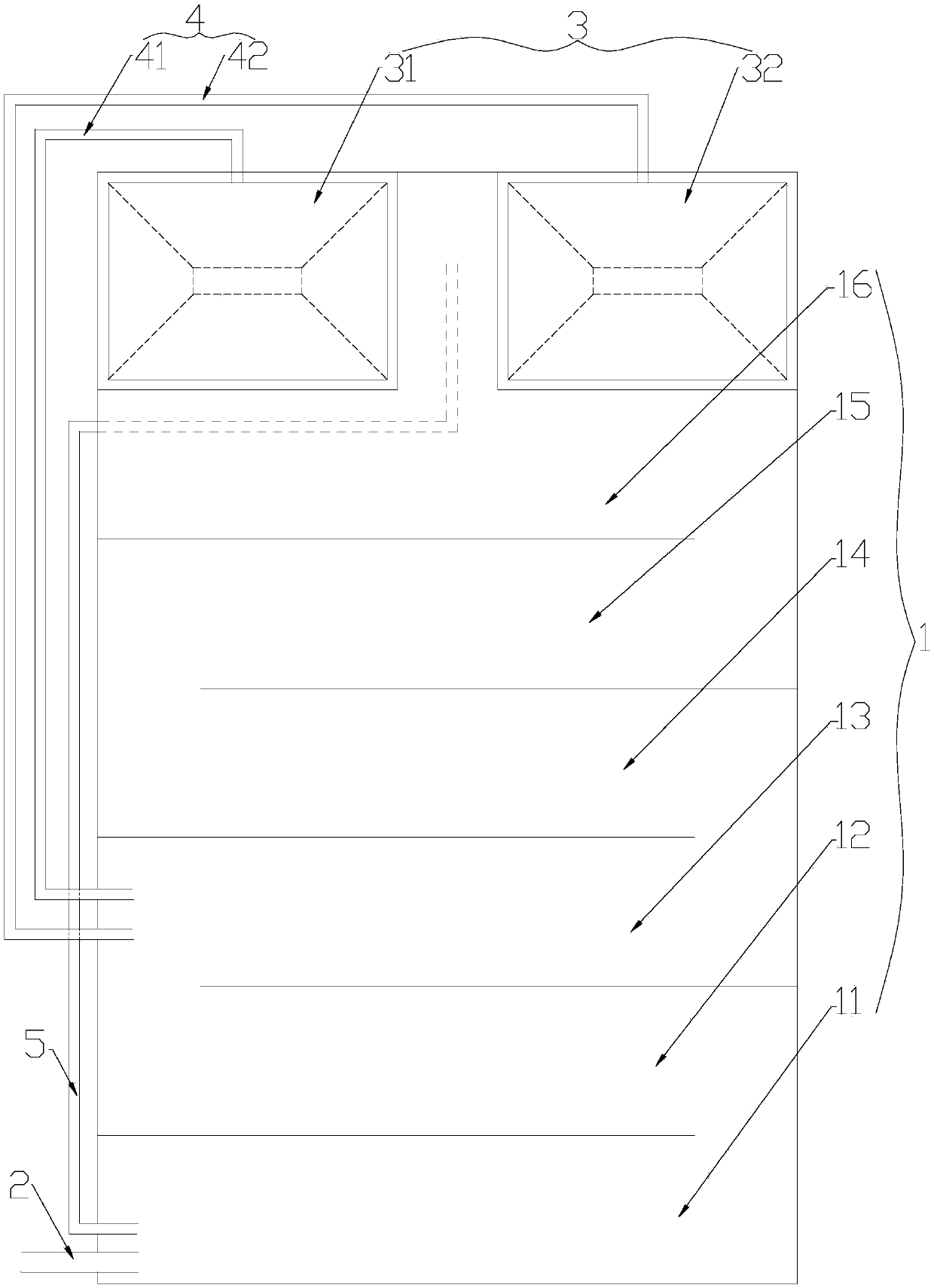

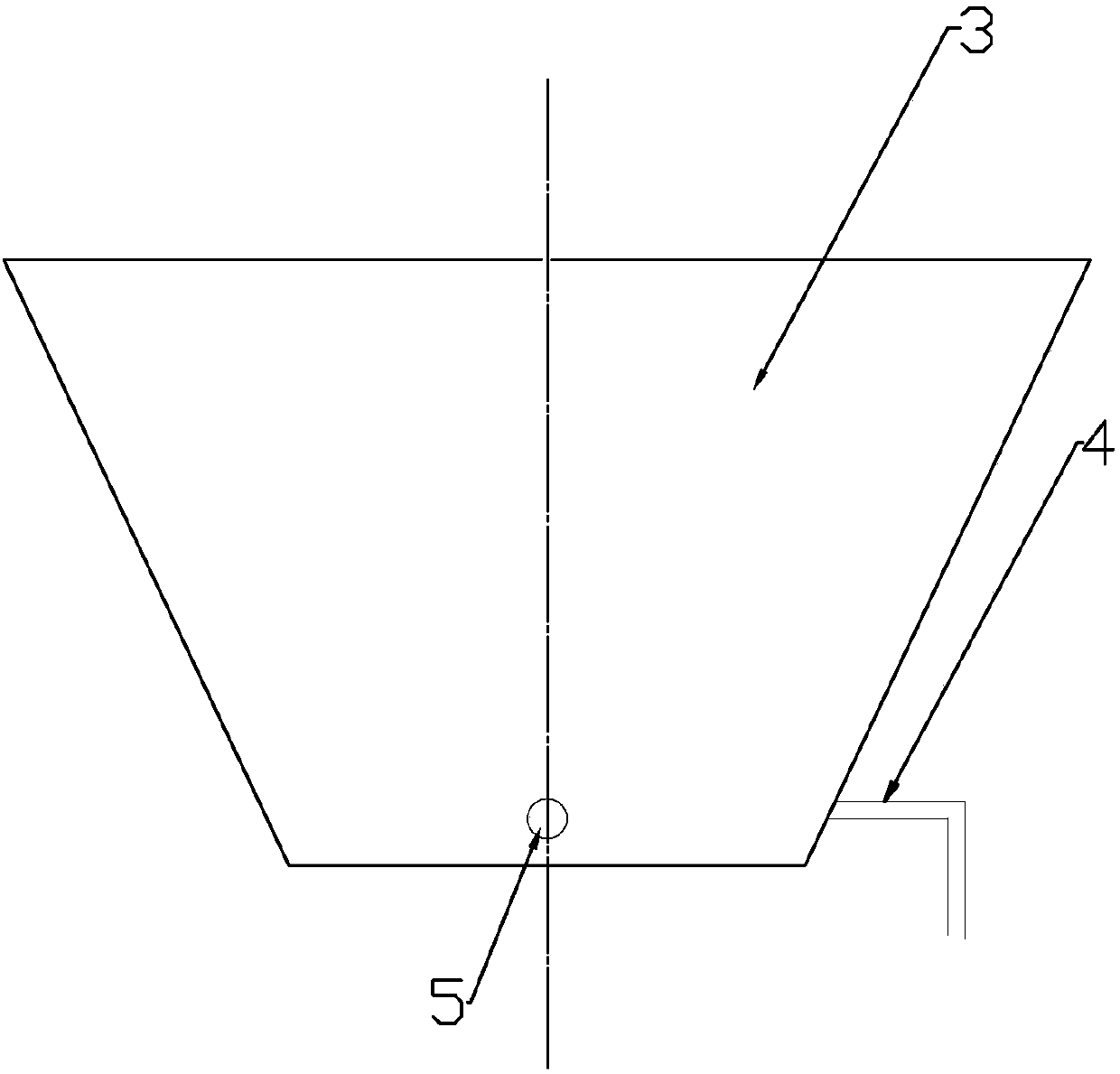

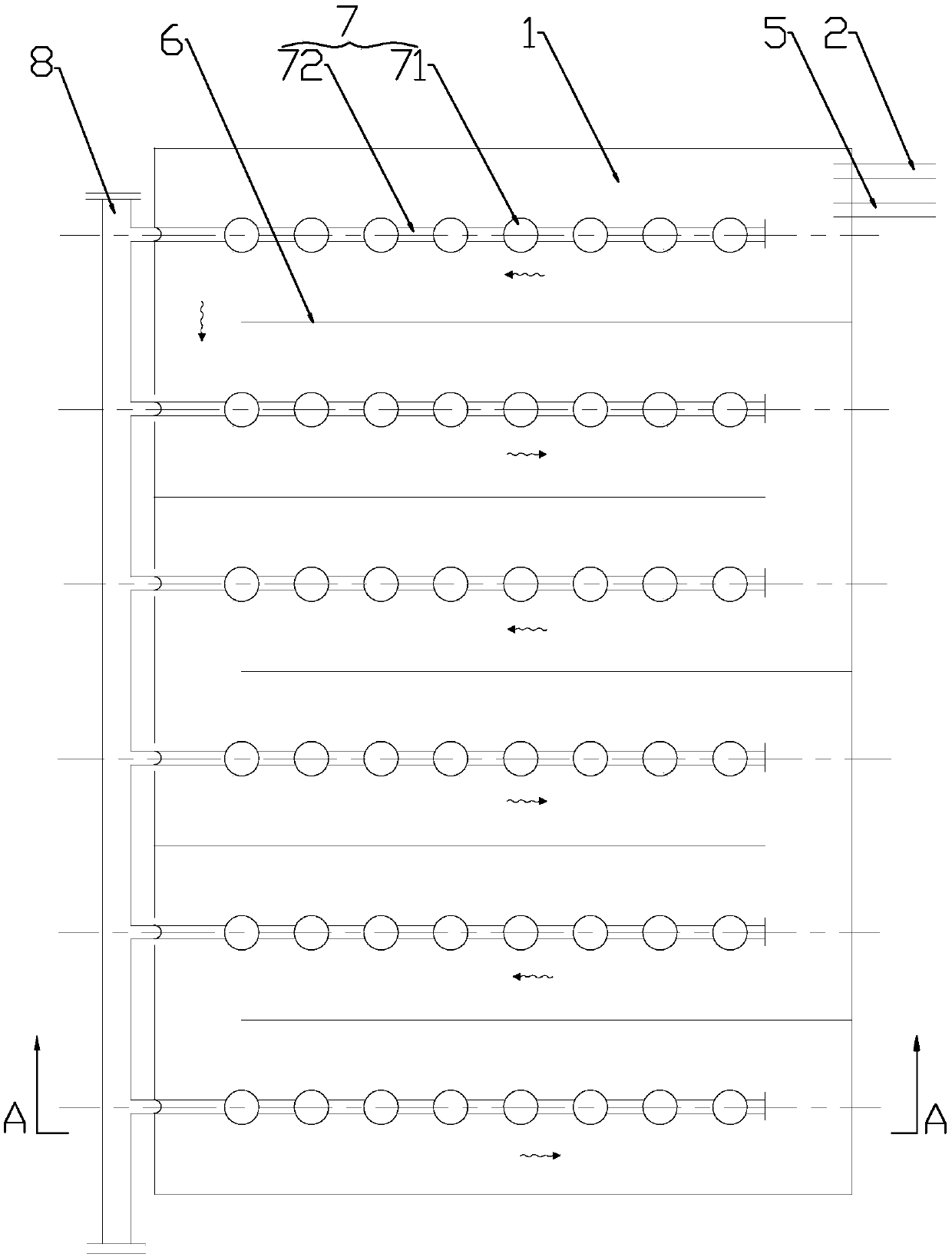

[0021] In this embodiment, a printing and dyeing wastewater denitrification process includes a treatment tank 1 and a sedimentation tank 3. The sedimentation tank 3 is located at the end of the treatment tank 1. Two anaerobic zones are sequentially arranged in the treatment tank 1, namely anaerobic zone-11 and anaerobic zone-11. Oxygen zone two 12, and four aeration zones, i.e. aeration zone one 13, aeration zone two 14, aeration zone three 15 and aeration zone four 16, anaerobic zone one 11, anaerobic zone two 12, aeration zone two Gas zone 13, aeration zone 2 14, aeration zone 3 15 and aeration zone 4 16 are connected end to end in sequence, the tail end of anaerobic zone 11 is connected with the head end of anaerobic zone 2 12, anaerobic zone 2 12 The tail end of the aeration zone 13 is connected with the head end of the aeration zone one 13, the tail end of the aeration zone one 13 is connected with the head end of the aeration zone two 14, the tail end of the aeration zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com