Flue gas condensation de-whitening defogging and dedusting tower

A technology of flue gas condensation and dust removal tower, which is applied in the direction of gas treatment, combined devices, membrane technology, etc., can solve the problems of not being able to meet the requirements of the emission indicators of smoke and dust pollutants, the inability to achieve whitening of flue gas, and high investment costs for environmental protection. Dust removal and whitening effect, compact structure, low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

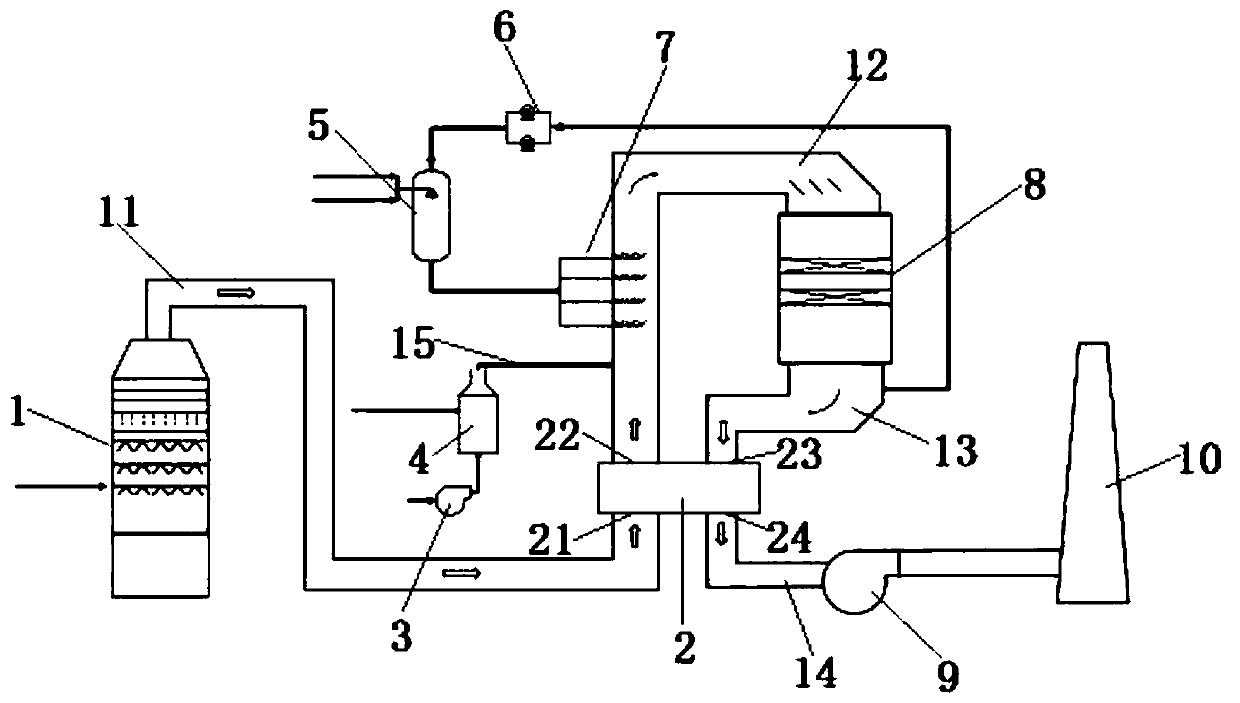

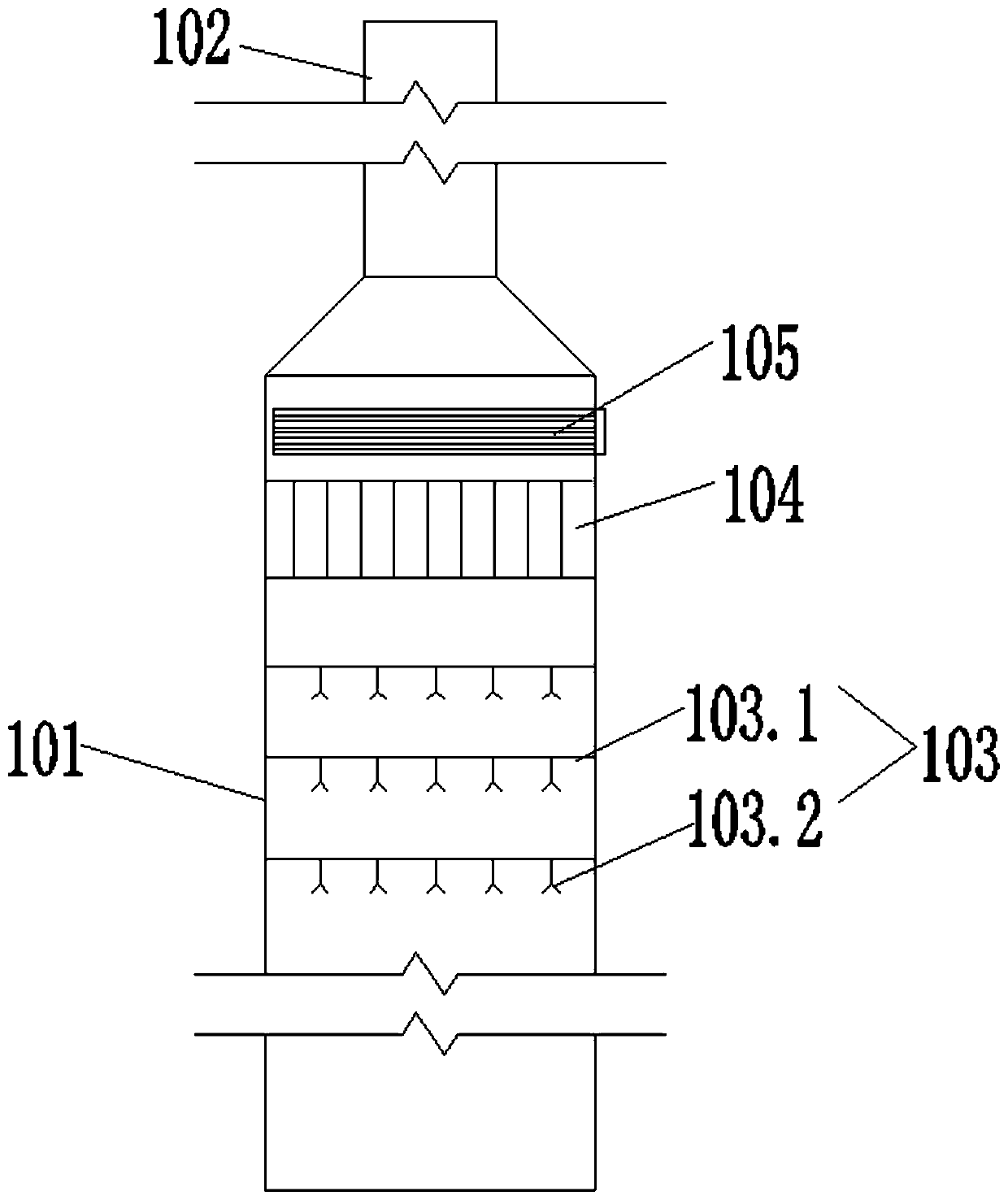

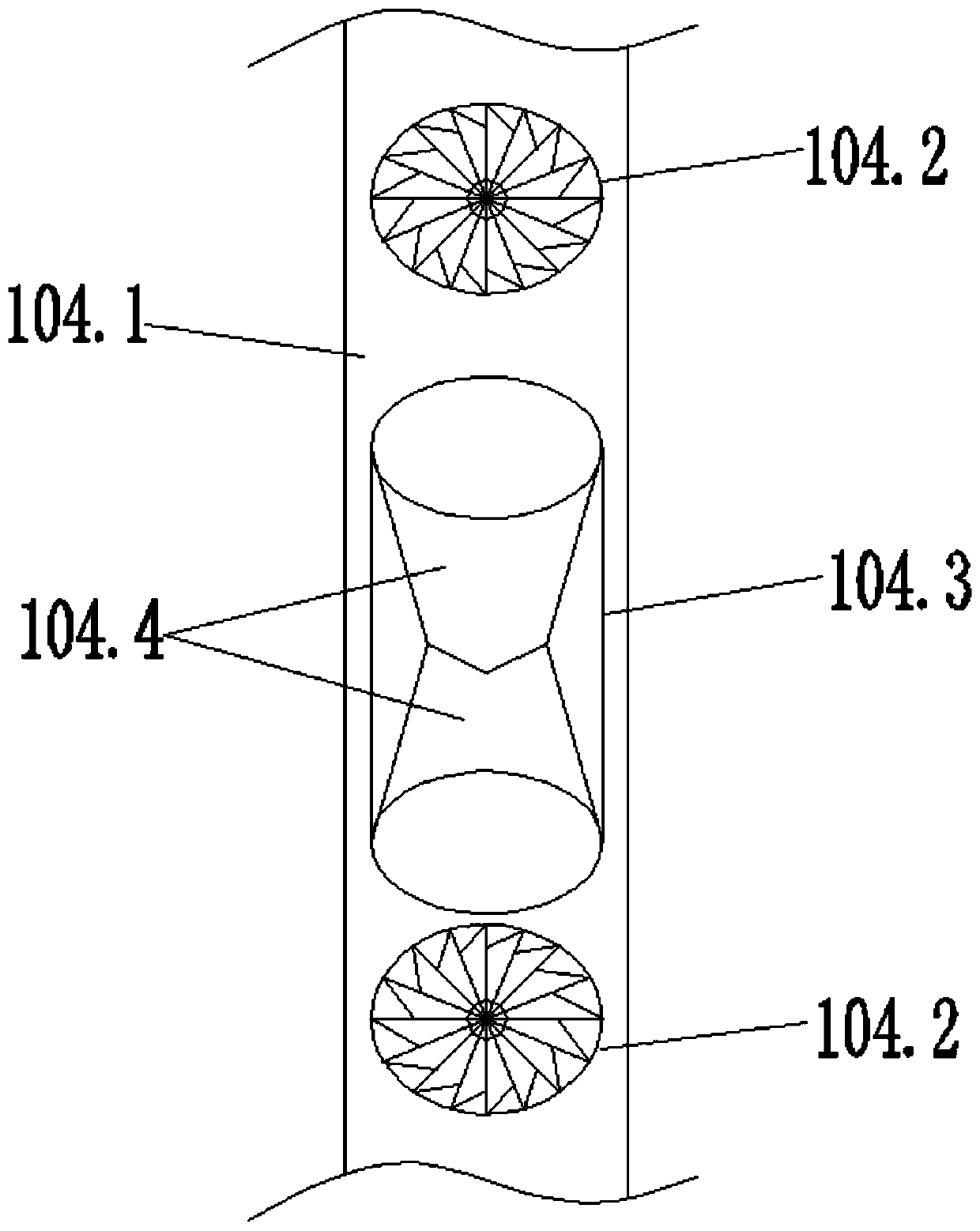

[0036] see Figure 1-Figure 4 , a sintering flue gas SCR denitrification and whitening system related to the present invention, comprising a flue gas condensation dewhitening demisting and dedusting tower 1, a heat exchange device 2, a hot blast stove 4, an ammonia water evaporator 5, a dilution fan 6, and an ammonia spraying grid 7. The SCR denitrification reaction device 8 and the smoke exhaust device 10, the first main flue 11 is connected between the raw flue gas inlet 21 at the lower part of the heat exchange device 2 and the gas outlet of the flue gas condensation, whitening, fogging and dust removal tower 1 , the second main flue 12 is connected between the original flue gas outlet 22 on the upper part of the heat exchange device 2 and the air inlet of the SCR denitrification reaction device 8, and the clean flue gas inlet 23 on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com