Determining method of mining roadway critical width

A critical width and recovery roadway technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of large deformation of surrounding rock, instability of two sides, roof fall of roadway, etc., and achieve low cost, simple construction, and low input cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

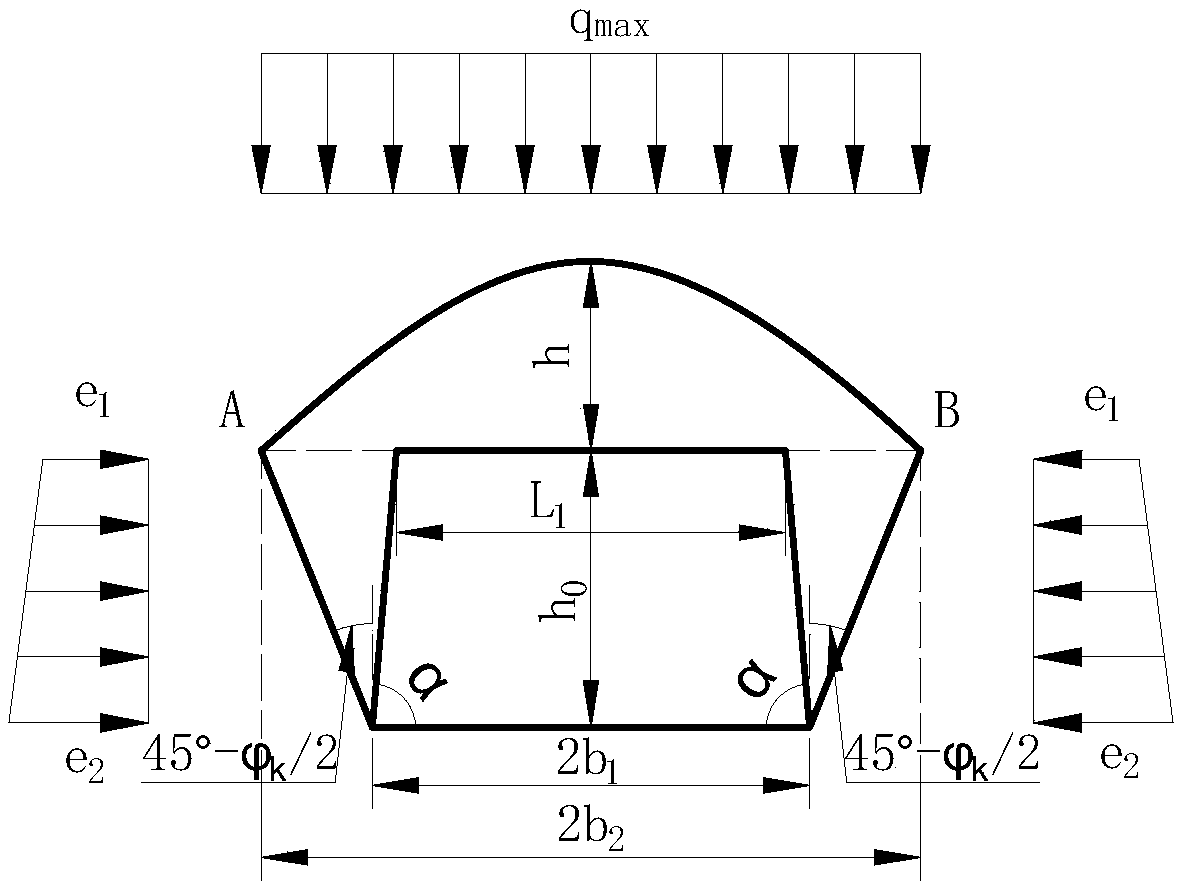

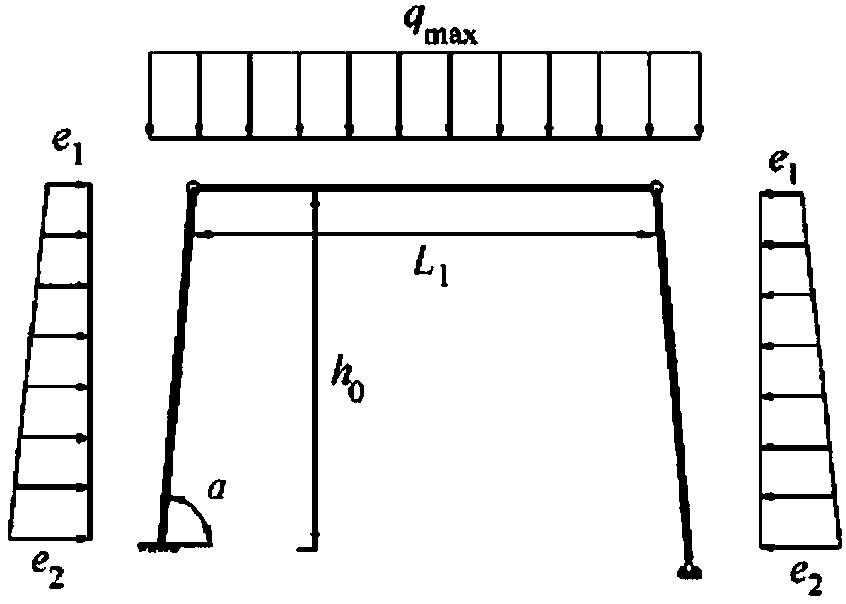

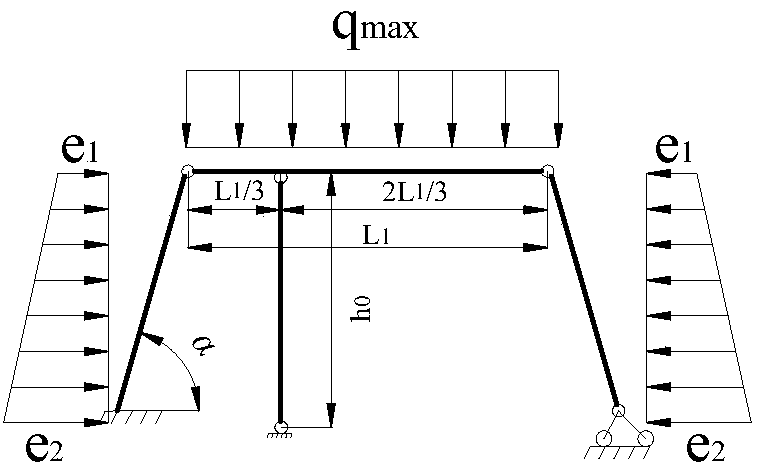

[0055] refer to Figure 1 to Figure 5 , this embodiment provides a method for determining the critical width of a mining roadway, and a method for determining the critical width of a mining roadway, including the following steps:

[0056] 1) Determine the main parameters of the Platts arch theory: the top of the mining roadway is the falling gangue from the upper coal seam working face and the top coal damaged by the upper layered working face, and the two sides are also broken coal bodies, and the cross-sectional shape of the roadway is equal to Waist trapezoid, to form a Platts arch above the roadway, the roadway burial depth H must be greater than 2 times the Platts arch height or 2.5 times the Platts arch span, which can meet the applicable conditions of the Platts arch theory.

[0057] (1) The firmness coefficient of the rock and the internal friction angle of the exchange number

[0058] According to the coal sample test done in the laboratory, the uniaxial compressive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com