Bearing fault diagnosis method

A fault diagnosis and bearing technology, which is applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of slow decomposition of endpoint effects and modal confusion, and achieve the effect of reducing the interference of human factors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

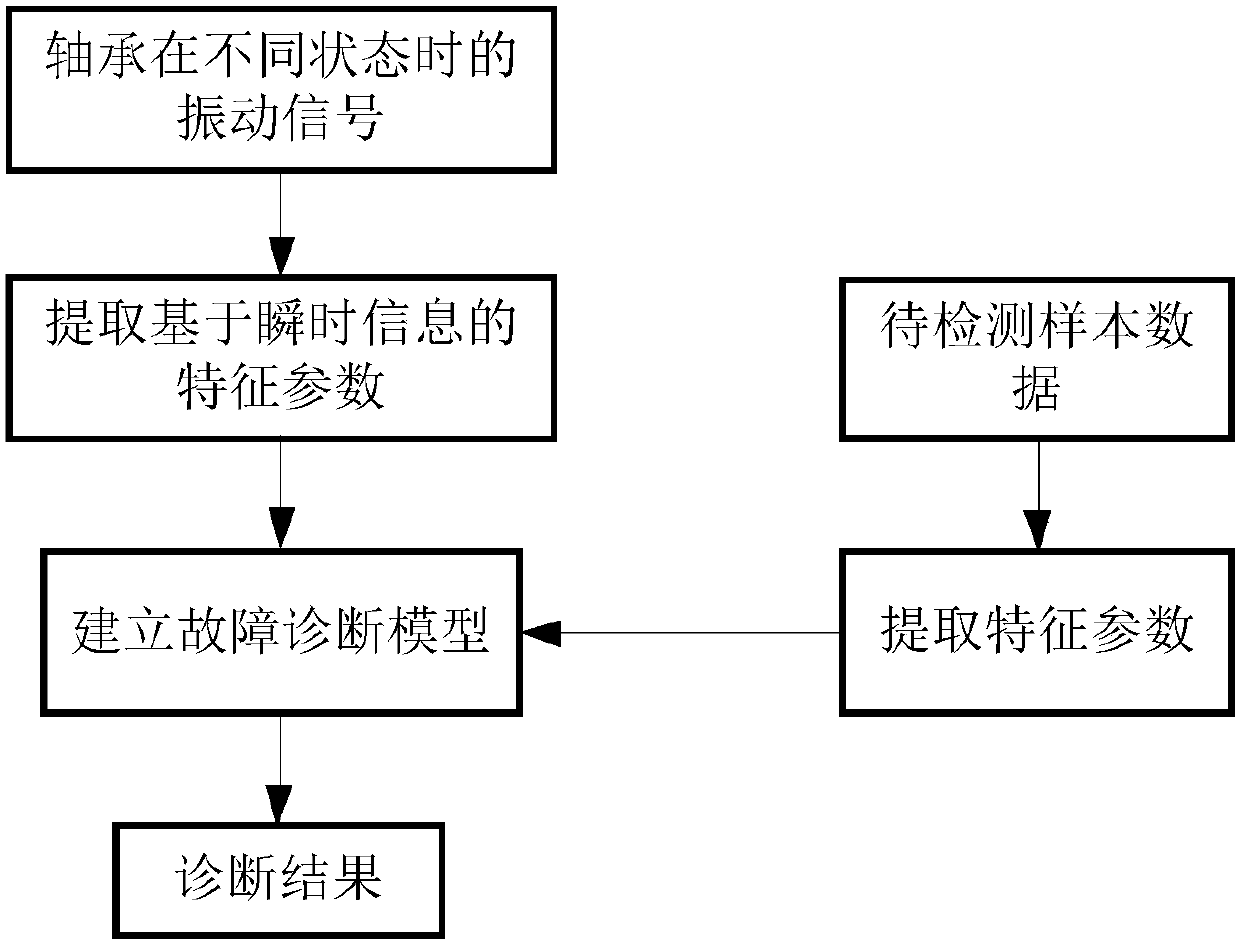

[0029] Such as figure 1 As shown, a bearing fault diagnosis method provided by the present invention includes the following steps:

[0030] 1) Obtain multiple sets of vibration acceleration signal data of the wind turbine main shaft bearing in different states, randomly select several sets as standard sample data, and the remaining sets as sample data to be tested.

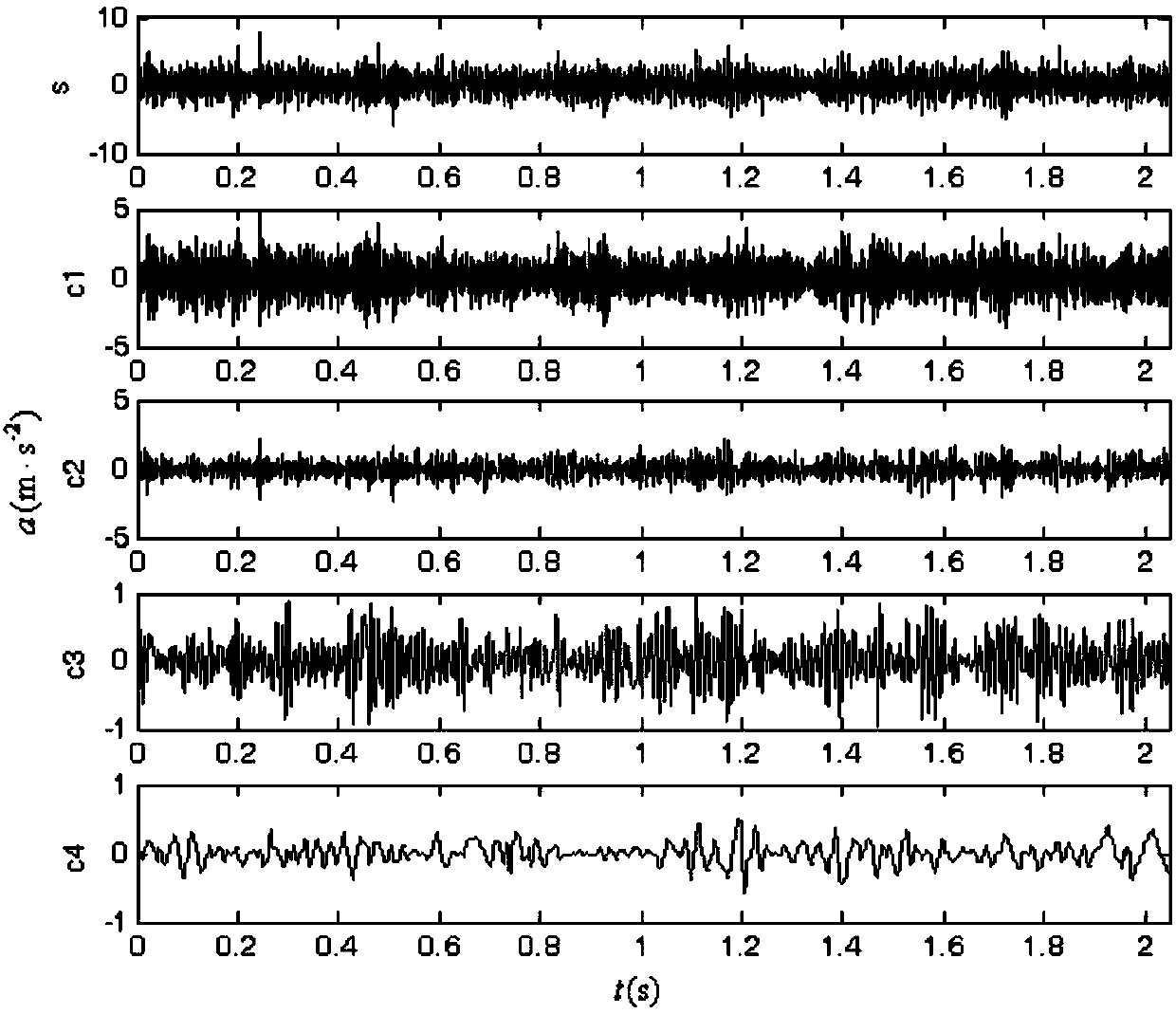

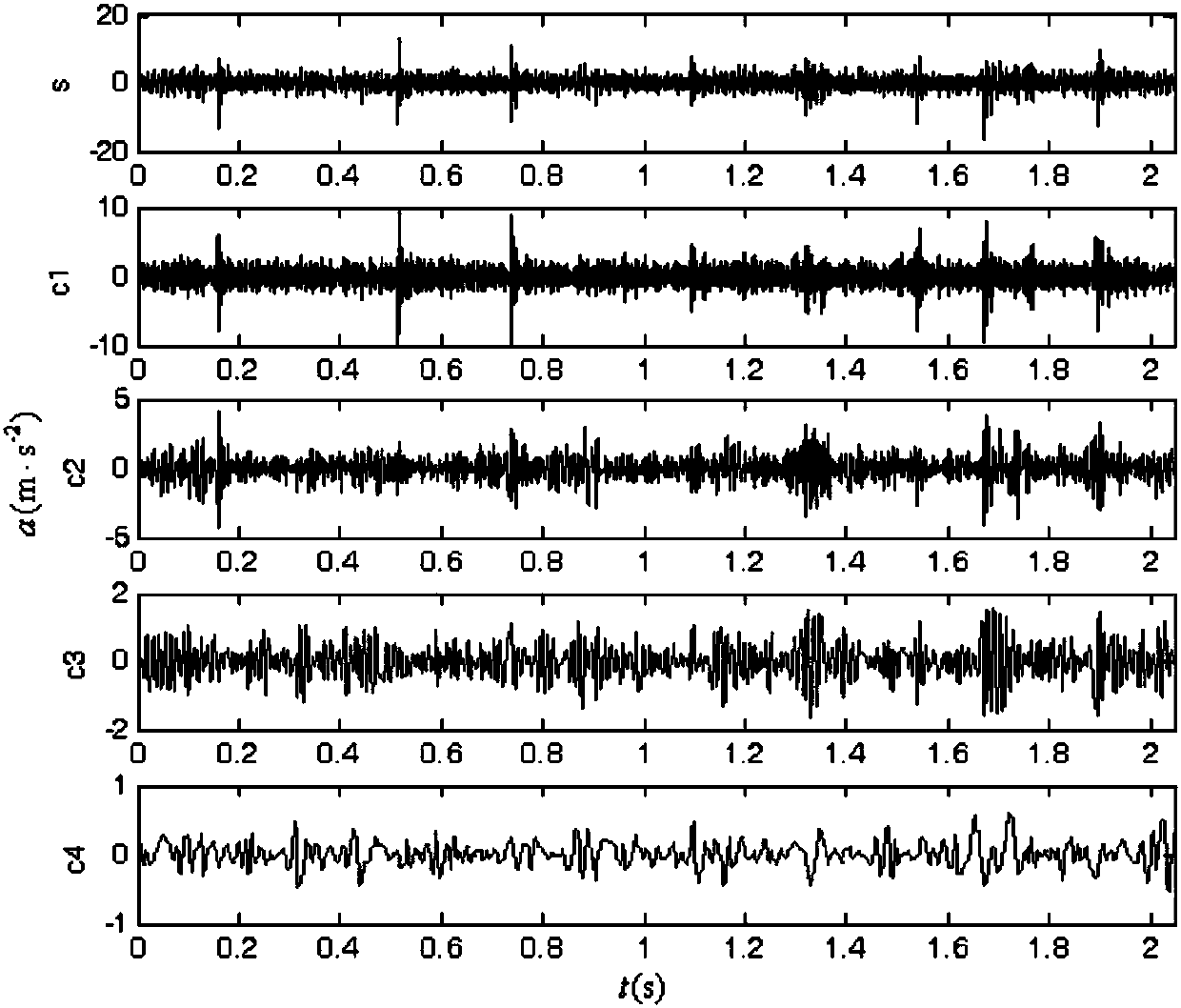

[0031] Due to the influence of wind conditions and the inherent characteristics of roller bearings, when the roller bearings of wind turbines fail, their vibration signals usually contain complex modulation components. The present invention adopts the self-aligning roller bearing that is often used in the actual wind turbine as the main shaft test bearing, and checks the normal operation status of the bearing through the frequent faults of the main shaft bearing of the direct drive wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com