Visual sensor system used for dry cell slurry layer paper winding defect detection and method thereof

A vision sensor and defect detection technology, applied in the field of vision sensors, can solve the problems of low reliability and efficiency of artificial vision methods, limited shooting angle of machine vision methods, etc., and achieve strong anti-interference ability, improved contrast ratio, and simple system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

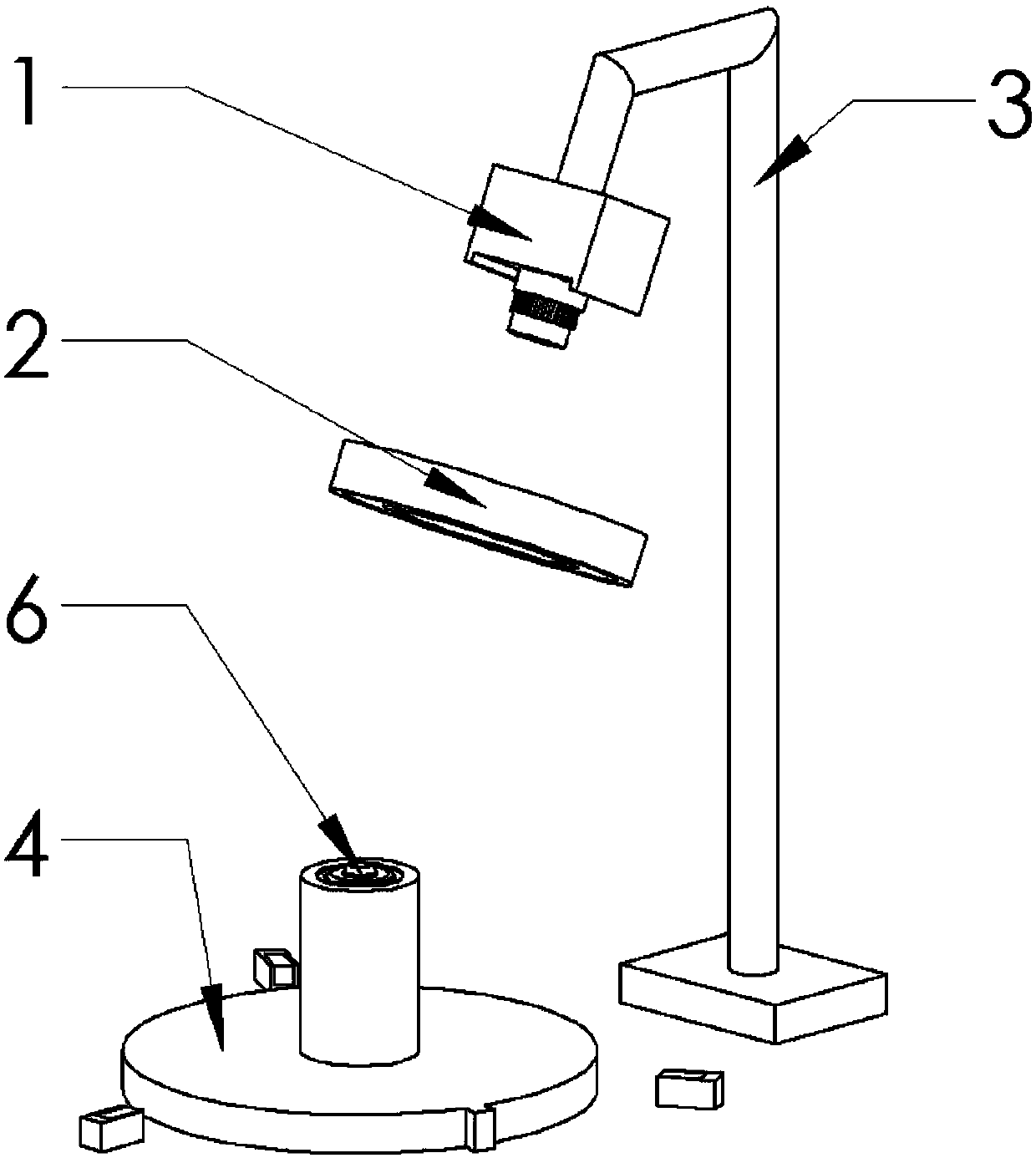

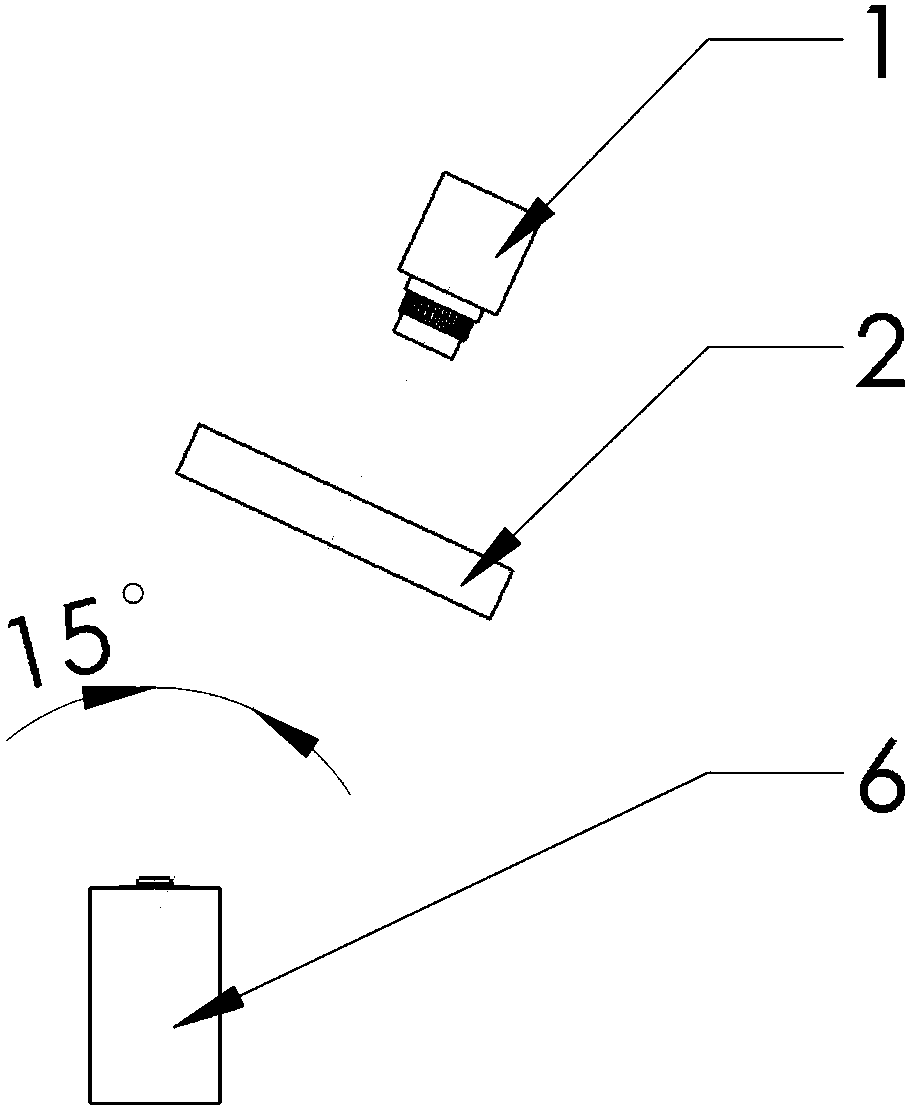

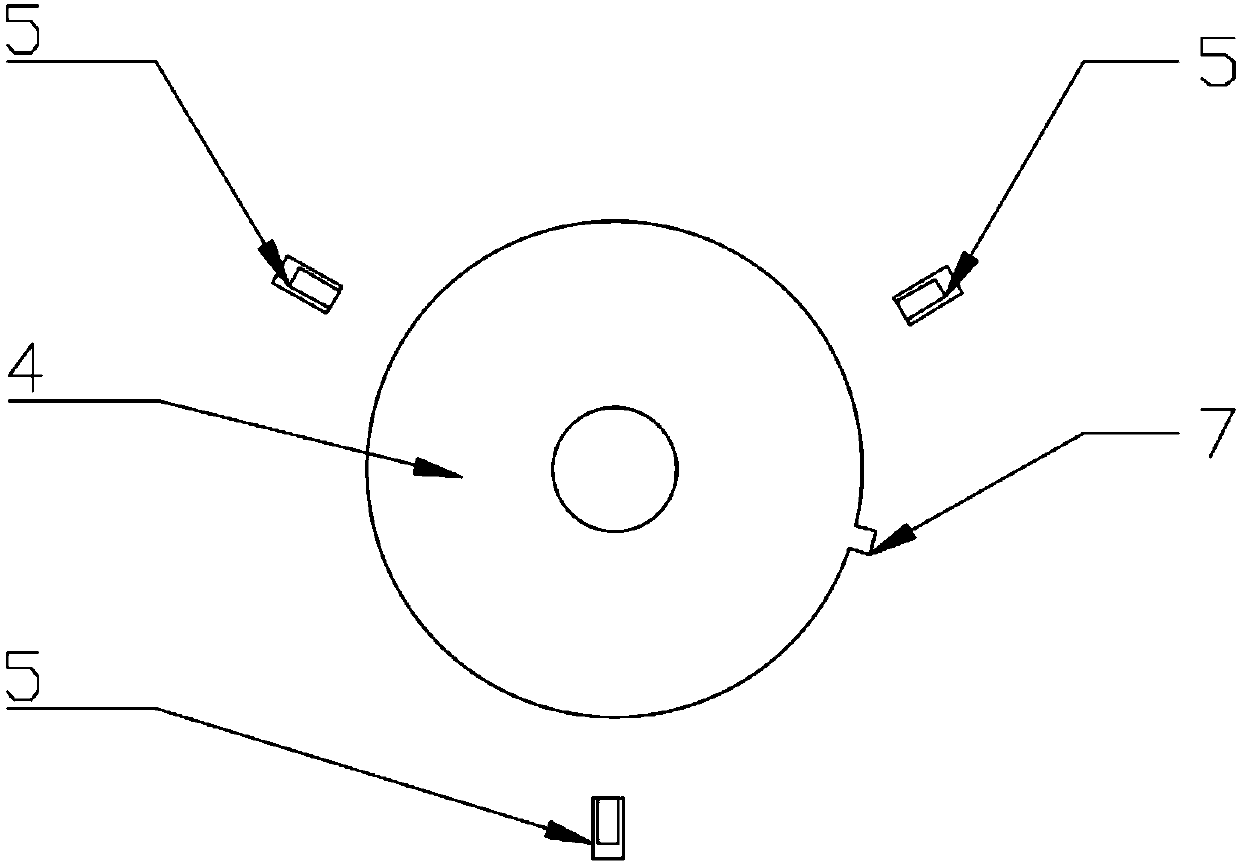

[0052] Such as Figure 1 to Figure 3 As shown, a visual sensor system for detection of dry battery pulp paper winding defects includes a visual sensor 1, a ring light source 2, a bracket 3, a turntable 4, and several synchronous trigger sensors 5, and the dry battery 6 to be detected is placed on the turntable 4 center, the turntable 4 keeps rotating around the central axis at a constant speed, and several synchronous trigger sensors 5 are evenly distributed on the side of the turntable 4 at equal intervals.

[0053] In this embodiment, the number of synchronous trigger sensors is 3, and the 3 synchronous trigger sensors 5 are evenly distributed on the side of the turntable 4 at intervals of 120 degrees. Similarly, four synchronous trigger sensors can also be used, and the four synchronous trigger sensors 5 are evenly distributed on the side of the turntable 4 at intervals of 90 degrees. The above-mentioned number of synchronous trigger sensors does not constitute a limitatio...

Embodiment 2

[0063] This embodiment is based on a visual sensor system for detection of winding defects of dry battery pulp paper disclosed in the above embodiments, and provides a method for detection of winding defects of dry battery pulp paper, as shown in Figure 4 As shown, the method for detecting the winding defects of dry battery pulp paper provided in this embodiment includes steps:

[0064] S1. The visual sensor 1 is initialized, and the synchronous trigger module, the light source driver module, the image processing module, etc. are sequentially set to default values;

[0065] S2. The visual sensor 1 loops to judge whether several synchronous trigger sensors 5 have generated switch signals, if any synchronous trigger sensor 5 has been triggered, go to the next step, otherwise continue to wait for the switch signal;

[0066] S3. The synchronous trigger module of the visual sensor 1 processes the position information obtained by the synchronous trigger sensor 5, generates a light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com