A method for additive manufacturing of plastic powder conformal stepped temperature bed

An additive manufacturing and temperature bed technology, which is applied in manufacturing tools, additive manufacturing, additive processing, etc., can solve the problems of unpopularity, high cost, and difficulty in applying large-scale additive manufacturing of plastic parts to prevent the decline of physical properties. , reduce costs, and achieve the effect of mass additive manufacturing of plastic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

[0035] A method for additive manufacturing of a plastic powder conformal stepped temperature bed, comprising the following steps:

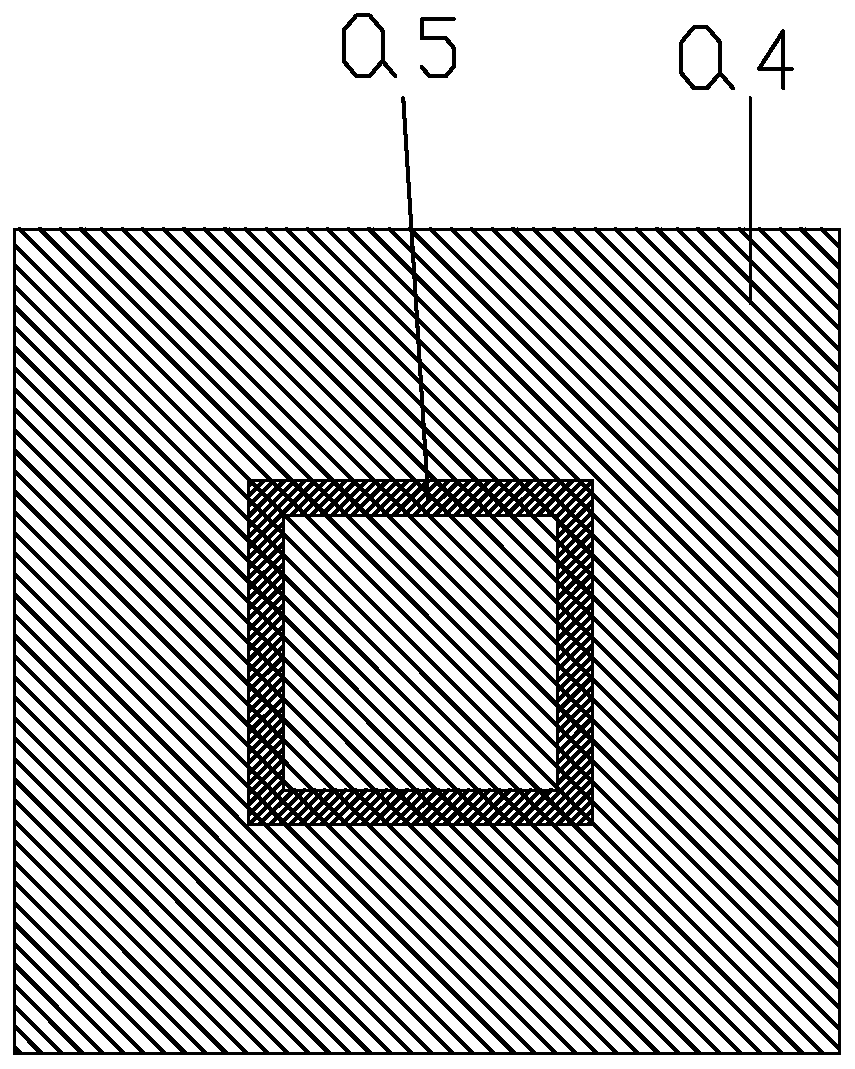

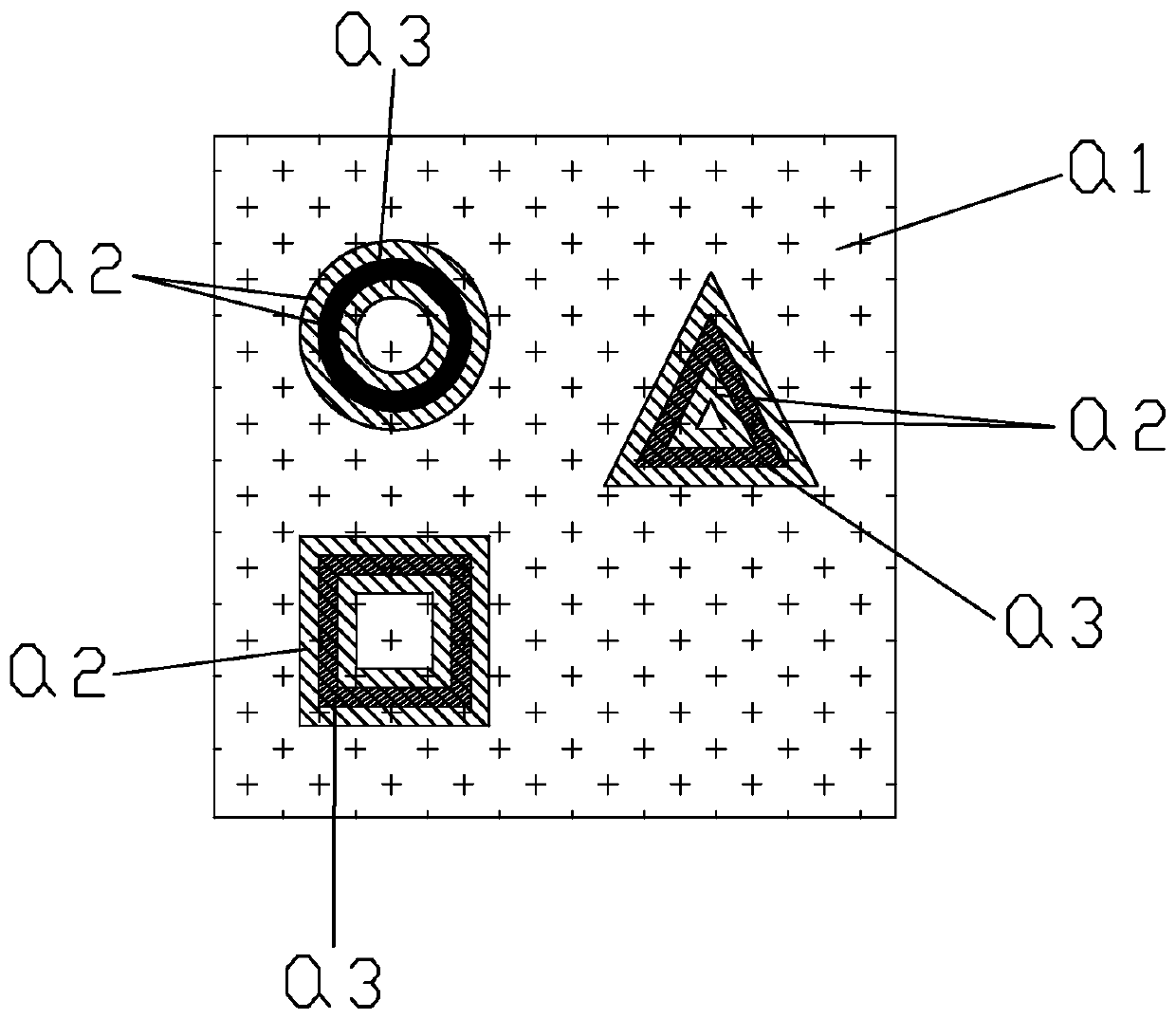

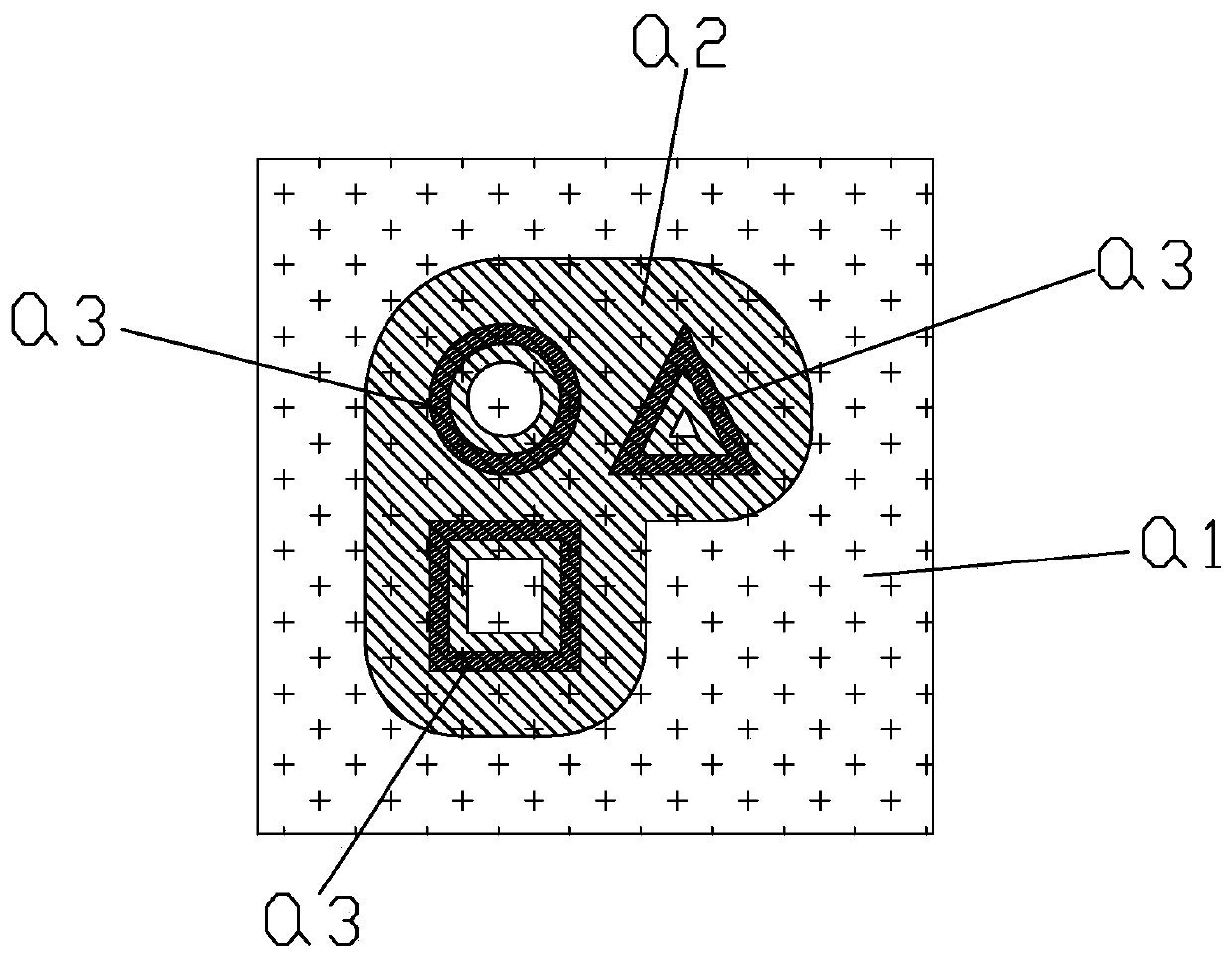

[0036] A. Slice the 3D digital model of the plastic product under a specific software and generate a file that expands the laser scanning path of the selected area a2 and sintering area a3, and then import the file into the laser sintering additive manufacturing system;

[0037] B. Adding powder: Add the plastic powder for sintering into the powder tank composed of powder spreading device;

[0038] C. Powder scraping: The scraper with plastic powder added to the powder tank moves on the working platform, and the plastic powder in the powder tank is evenly spread on the working platform through the scraper;

[0039] D. Primary heating: heat the plastic powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com