A method for melting and crystallizing separation and purification of o-iodoaniline

A technology of melting crystallization and o-iodoaniline, which is applied in the field of separation and purification of o-iodoaniline, can solve the problems of only 45% yield, easy deterioration, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

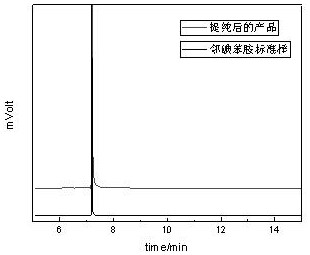

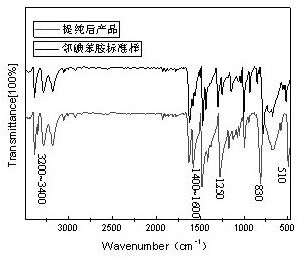

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of method that melt crystallization separates and purifies o-iodoaniline, comprises the following steps:

[0032] 1) Select a mixture of o-iodoaniline and p-iodoaniline, which accounts for 55% of the total mass fraction, as a raw material, and grind it into powder to obtain product A;

[0033] 2) Put product A into the crystallizer, then open the crystallizer, heat product A to 75°C to completely melt product A, and obtain product B;

[0034] 3) Cool product B at a rate of 5°C / h to make it crystallize, grow crystals for 0.5 hours after reaching the final crystallization temperature of 50°C, and then release the mother liquor to obtain product C;

[0035] 4) The product C is gradually heated up at a rate of 5°C / h to sweat until the final sweating temperature is 60°C, and sweat is released, and the remaining crystals are purified o-iodoaniline.

Embodiment 2

[0036] Embodiment 2: a kind of method that melt crystallization separates and purifies o-iodoaniline, comprises the following steps:

[0037] 1) Select a mixture of o-iodoaniline and p-iodoaniline, which accounts for 65% of the total mass fraction, as a raw material, and grind it into powder to obtain product A;

[0038] 2) Put product A into the crystallizer, then open the crystallizer, heat product A to 65°C to completely melt product A, and obtain product B;

[0039] 3) Cool product B at a rate of 4.1°C / h to crystallize it, grow crystals for 2 hours after reaching the final crystallization temperature of 42°C, and then release the mother liquor to obtain product C;

[0040] 4) The product C is gradually heated up at a rate of 4.1°C / h to sweat until the final sweating temperature is 50°C, and sweat is released, and the remaining crystals are purified o-iodoaniline.

Embodiment 3

[0041] Embodiment 3: a kind of method of melt crystallization separation and purification o-iodoaniline, comprises the following steps:

[0042] 1) Select a mixture of o-iodoaniline and p-iodoaniline, which accounts for 75% of the total mass fraction, as a raw material, and grind it into powder to obtain product A;

[0043] 2) Put product A into the crystallizer, then open the crystallizer, heat product A to 55°C to completely melt product A, and obtain product B;

[0044] 3) Cool product B at a rate of 3°C / h to crystallize it, grow crystals for 5 hours after reaching the final crystallization temperature of 33°C, and then release the mother liquor to obtain product C;

[0045] 4) The product C is gradually heated up at a rate of 3°C / h to sweat until the final sweating temperature is 40°C, and sweat is released, and the remaining crystals are purified o-iodoaniline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com