Anti-corrosion technology of steel structure

A technology of steel structure and process method, which is applied in the direction of anti-corrosion coating, hot-dip plating process, metal material coating process, etc., can solve the problems of inability to protect the steel structure well, the protective layer loses its protective effect, the anti-corrosion life and the process flow are not good. Satisfactory and other problems, to achieve the effect of not easy to damage and peel off, prolong the service life, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0038] Example one

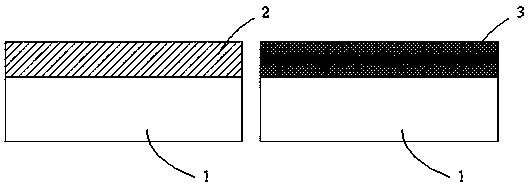

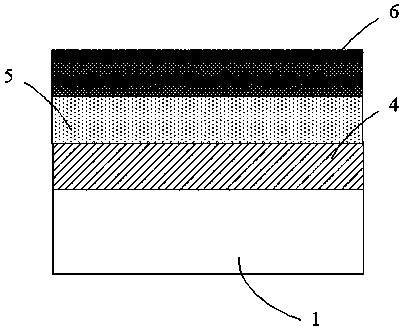

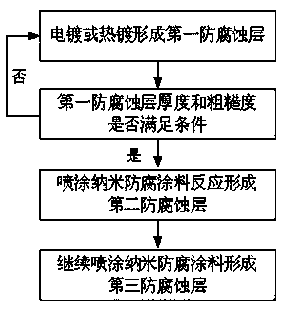

[0039] figure 1 It is a schematic diagram of a traditional steel structure anticorrosion protection layer. Metal plating and spraying anticorrosion coatings are the two most common steel structure anticorrosion processes. Steel structure 1 is coated with a metal layer 2 or steel structure 1 is sprayed with an anticorrosive coating layer. 3. figure 2 It is a protective layer structure formed by the anti-corrosion process of the steel structure of the present invention. The anti-corrosion process forms a total of three anti-corrosion layers: the first anti-corrosion layer 4, the second anti-corrosion layer 5 and the third anti-corrosion layer 6. image 3 It is a flow chart of the anti-corrosion process of the steel structure of the present invention.

[0040] First, perform surface pretreatment on the welded steel structure 1 to remove the grease and floating rust on the steel structure 1. The alkaline cleaning degreasing method can be used to remove the grease o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com