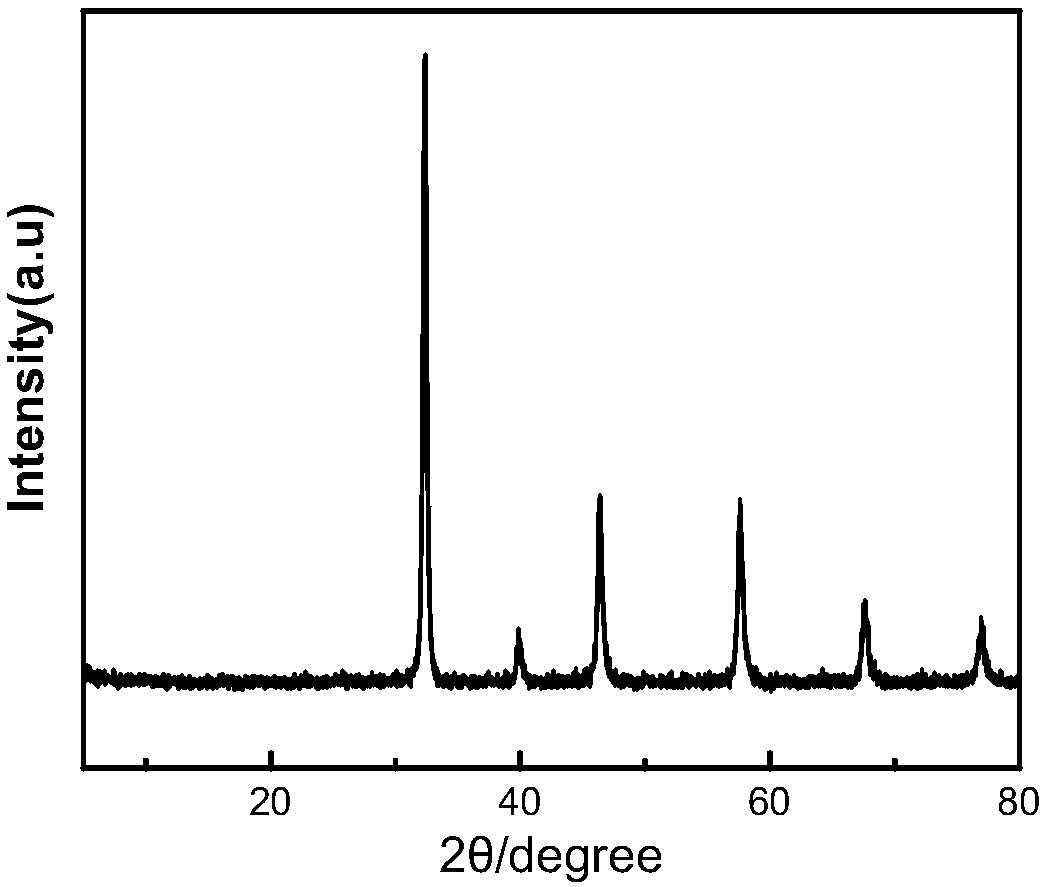

Preparation method of strontium iron molybdenum based double-perovskite type metal oxide nano-fibers

A double perovskite and nanofiber technology, applied in the direction of inorganic raw materials such as artificial filaments, can solve the problems of refractory solubility, difficulty in maintaining a complete structure of nanofibers, and difficulty in producing electrospinning precursors of metal elements, etc., to achieve structural The effects of integrity, excellent electrochemical performance, high catalytic activity and gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Sr below 2 Fe 1.1 Cu 0.4 Mo 0.5 o 6 Take an example to further illustrate the synthesis of strontium-iron-molybdenum-based double perovskite metal oxide nanofibers.

[0035] (1) Prepare 0.001mol electrospinning solution. Sr 2 Fe 1.1 Cu 0.4 Mo 0.5 o 6 Nanofiber material using Sr(Ac) 2 , (NH 4 ) 6 Mo 7 o 24 4H 2 O, Fe(NO 3 ) 3 9H 2 O, Cu(Ac) 2 Metal salt is used as raw material, citric acid is used as complexing agent, PVP (K88-96) is used as polymer, and DMF (dimethylformamide) is used as solvent. Accurately weigh the required raw materials according to the stoichiometric ratio.

[0036]

[0037] (2) Dissolve the accurately weighed metal salt and citric acid in 6.4g DMF, stir for 12 hours until the metal salt is completely dissolved; then add PVP polymer to the solution and continue stirring until completely dissolved to obtain a viscous solution.

[0038] (3) Set up the spinning device, inject the completely dissolved spinning solution into the inj...

Embodiment 2

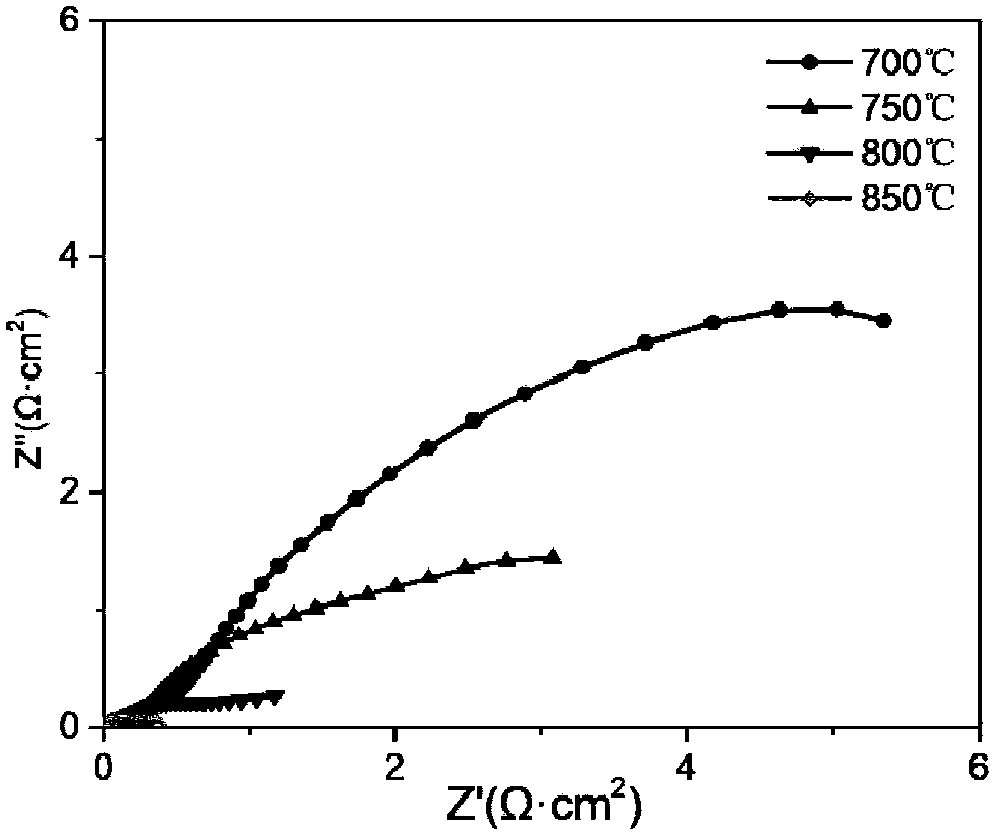

[0041] With the Sr that embodiment 1 makes 2 Fe 1.1 Cu 0.4 Mo 0.5 o 6 (SFCM) as an example to conduct nanofibers in CO 2 The test of the AC impedance curve under the atmosphere.

[0042] The electrolyte support used in the experiment is LSGM (La 0.8 Sr 0.2 Ga 0.8 Mg 0.2 o 3 ), prepared by tableting method. Specific steps are as follows:

[0043] Weigh 0.5g of LSGM powder in a mortar, use a pipette to measure 0.5mL of 5% polyvinyl alcohol (PVA) solution as a binder, and add it to the mortar. Grind until the powder is dry and fine enough. Put the powder into the mold, hold the pressure at 9 MPa for 4 minutes, pressurize to 18 MPa and hold the pressure for 4 minutes to obtain a disc-shaped electrolyte green body, and calcinate it at 1450 ° C for 8 hours to make it dense, and obtain the required LSGM electrolyte support (black circle sheet), and the electrolyte sheet was polished to a thickness of 300 μm, and ultrasonically cleaned for later use.

[0044] The electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap