Flat wall-attaching flame ultralow NOx gas burner

A gas burner and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of substandard NOx emission, uneven temperature distribution, poor wall attachment effect, etc., and achieve energy saving, The effect of attaching to the wall is good, and the effect of reducing the flame height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

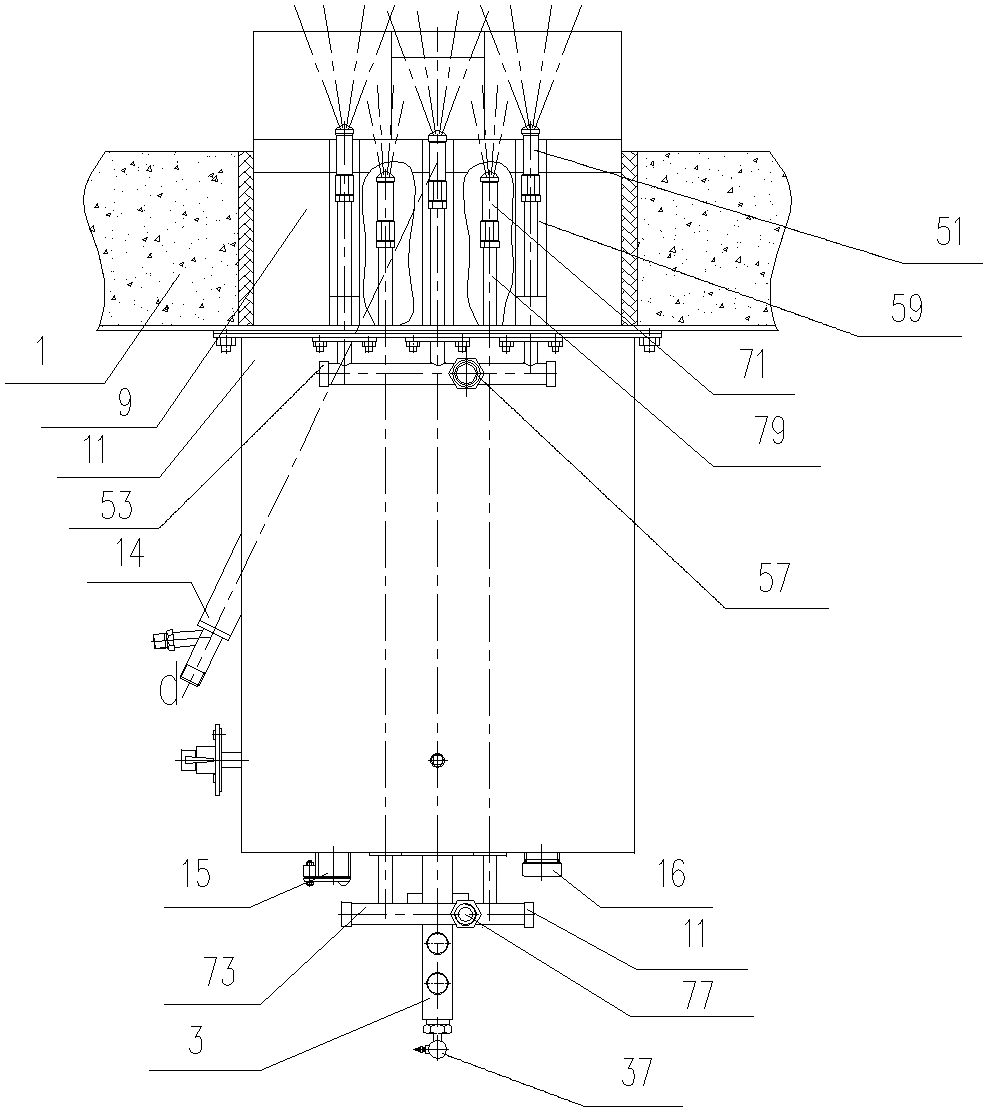

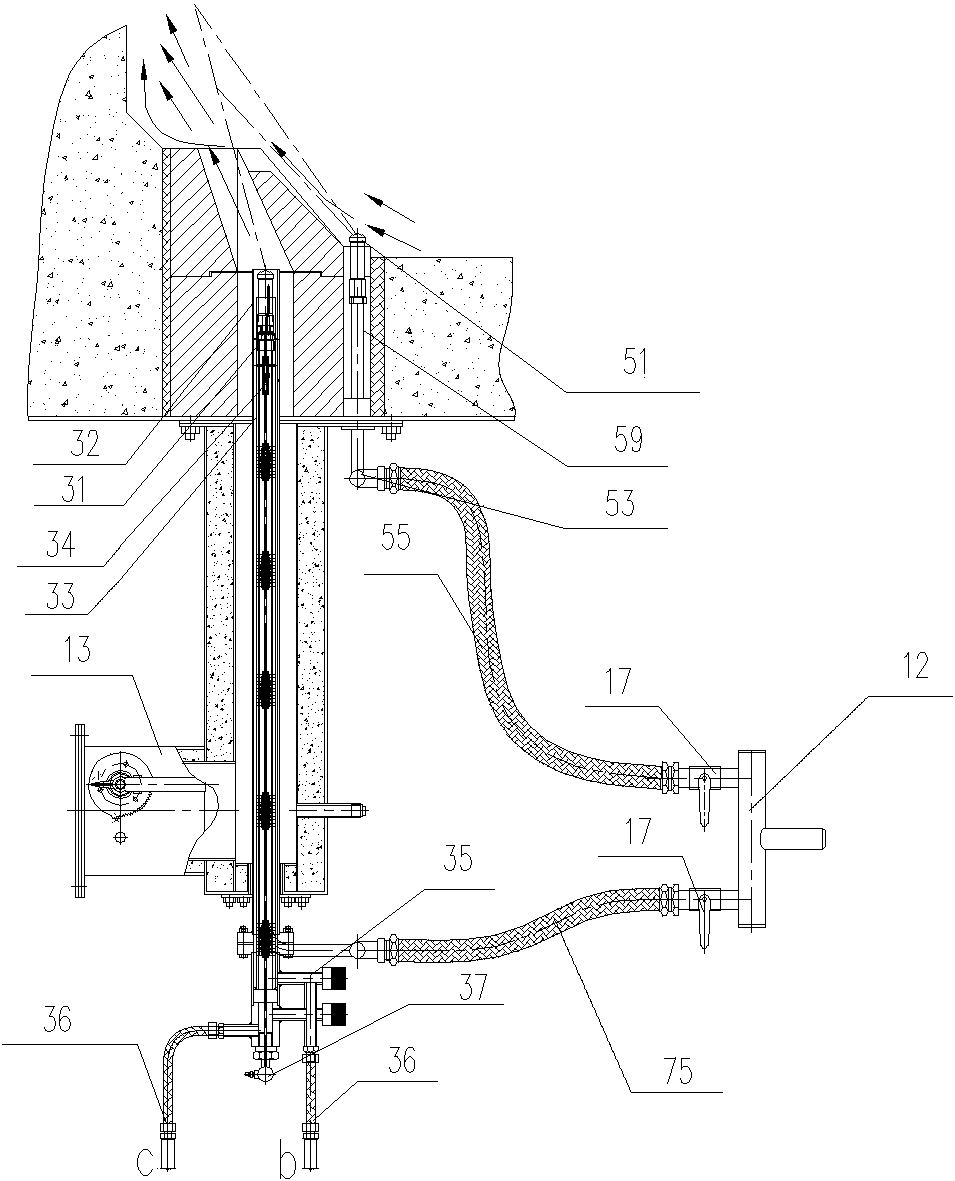

[0043] Such as Figure 1 to Figure 3 As shown, a flat wall-flame ultra-low NOx gas burner is arranged in a heating furnace 1, and includes a burner main body 11, a long light 3, an outer gas gun part, an inner gas gun part, a tee 12, a brazier brick 9, Air adjustment mechanism 13, fire detector 14, ignition hole 15, fire viewing hole 16, two regulating ball valves 17, 3 outer gas gun grooves 91.

[0044] Wherein, the top of the burner main body 11 is provided with a brazier brick 9 communicating therewith.

[0045] Specifically, the side of the burner body 11 is provided with an air regulating mechanism 13 and a flame detector 14 respectively communicating with it. One end of long light 3 passes in the bottom of burner main body 11 and stretches in the brazier brick 9. The bottom of the burner body 11 is provided with an ignition hole 15 and a fire viewing hole 16 .

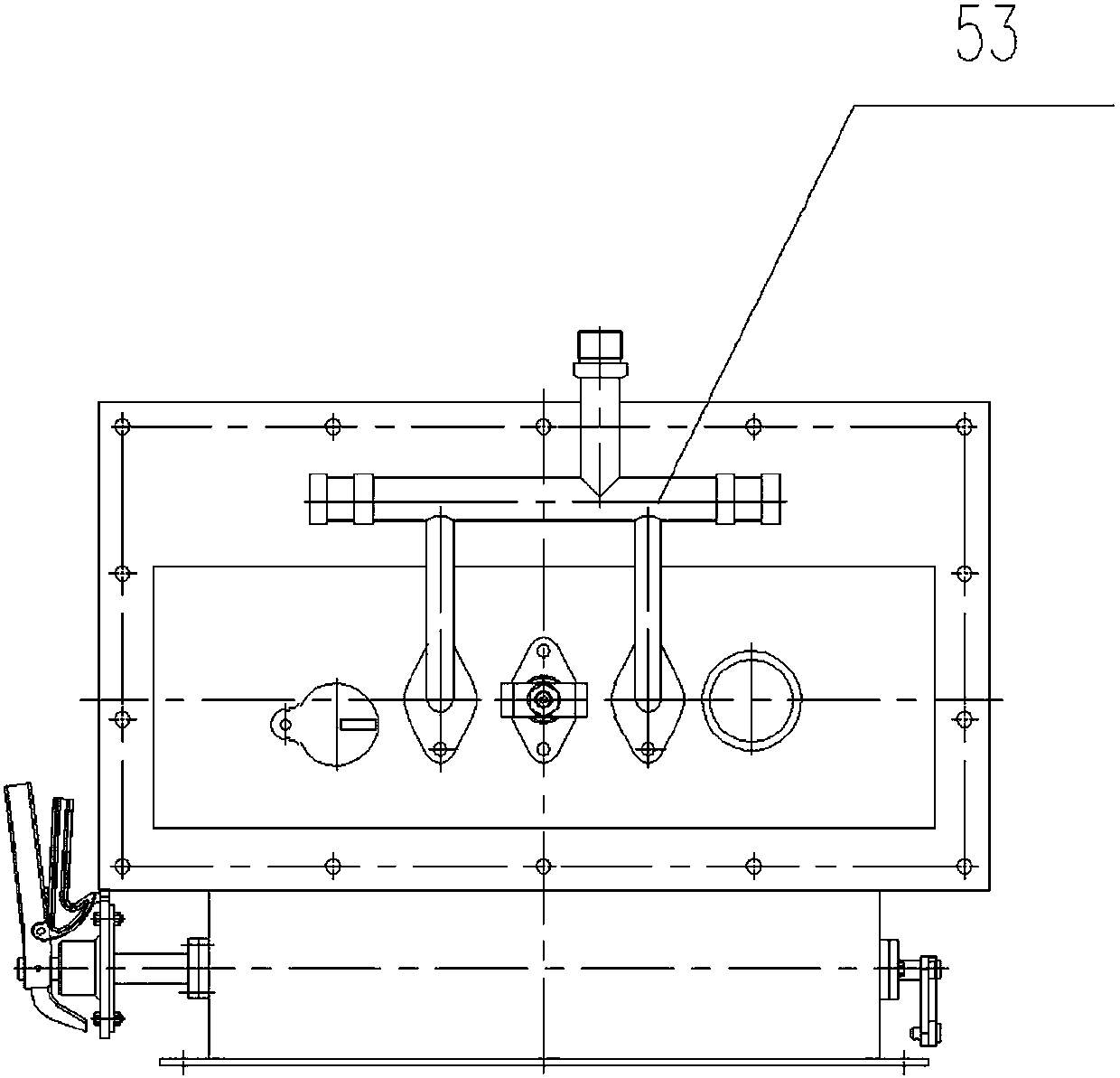

[0046] Such as Figures 4 to 8 Shown, brazier brick 9 is a hollow structure.

[0047] Specifically, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com