Biomass boiler and industrial waste heat combined heating technology

A biomass boiler, industrial waste heat technology, applied in hot water central heating systems, heating fuels, heating methods, etc., can solve the problems of high-grade energy consumption, waste of energy, low energy efficiency, etc., and improve heating energy efficiency. , the effect of eliminating energy consumption and expanding the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

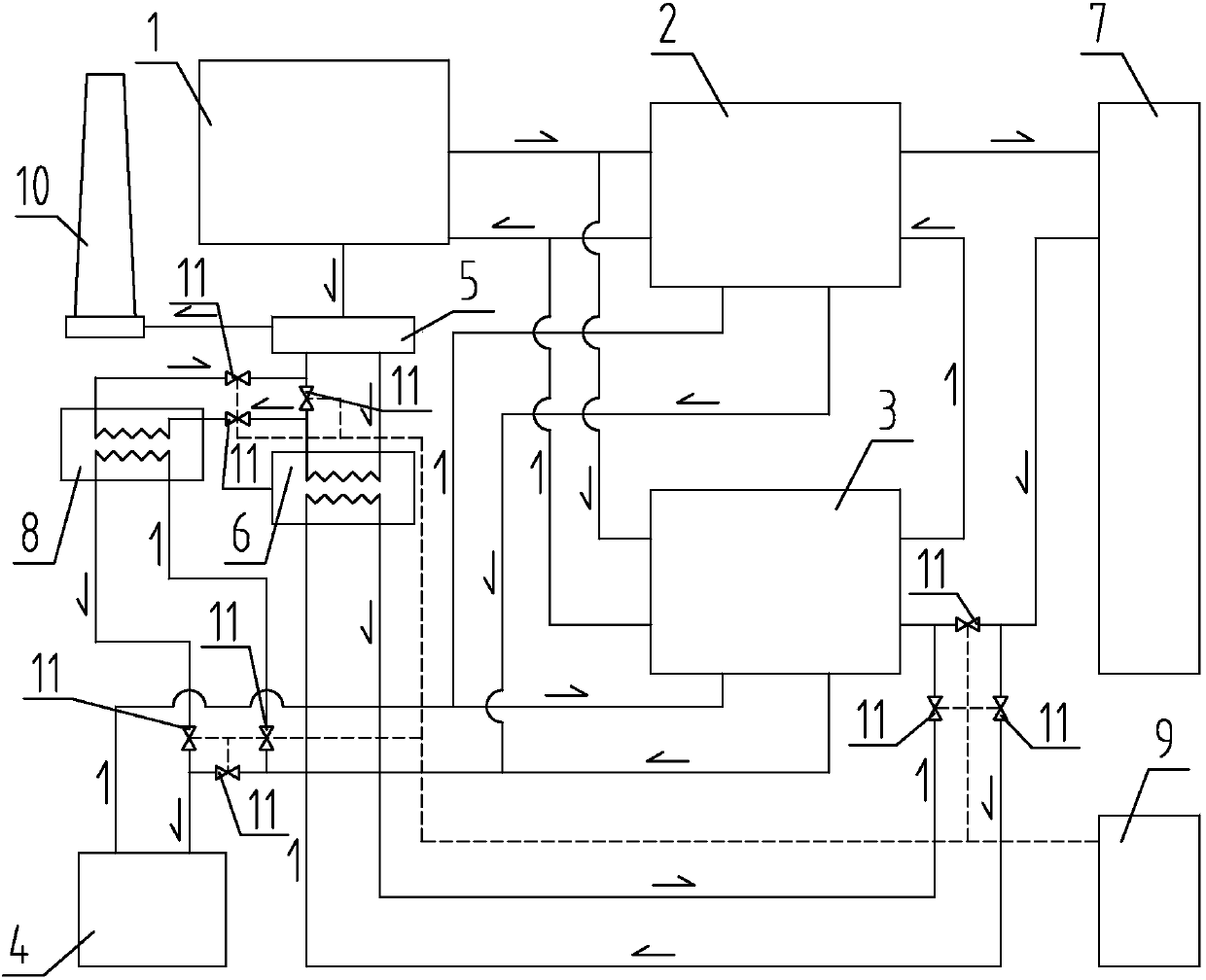

[0025] Using biomass boiler 1, the heating steam simultaneously drives single-effect absorption heat pump 2, double-effect absorption heat pump 4, and industrial waste heat 5, and supplies them as low-temperature heat sources in parallel to single-effect absorption heat pump 2 and double-effect absorption heat pump 3 respectively. ;

[0026] Industrial waste heat 5, the return water passes through the secondary flue gas waste heat heat exchanger 8 for heat exchange, recovers the waste heat of the flue gas, returns water through the industrial waste heat 5, and transports it back to the factory for industrial production;

[0027] The primary flue gas waste heat heat exchanger 6 is a residential area 7, and the return water is heated once. After heating, the double-effect absorption heat pump 3 is used for secondary heating. After the secondary heating, the single-effect absorption heat pump 2 is used for three times. Heating, after three times of heating, it is transported to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com