Manufacturing method of oriented fluid inclusion thin sheet of wild outcrop sand rock sample

A fluid inclusion and field outcrop technology, which is applied in the field of making directional fluid inclusion thin slices of field outcrop sandstone samples, can solve the problem that the interaction between tectonic fractures and crustal fluid cannot be well interpreted, the structural properties of fluid inclusion surfaces are ignored, and the wrong research conclusions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

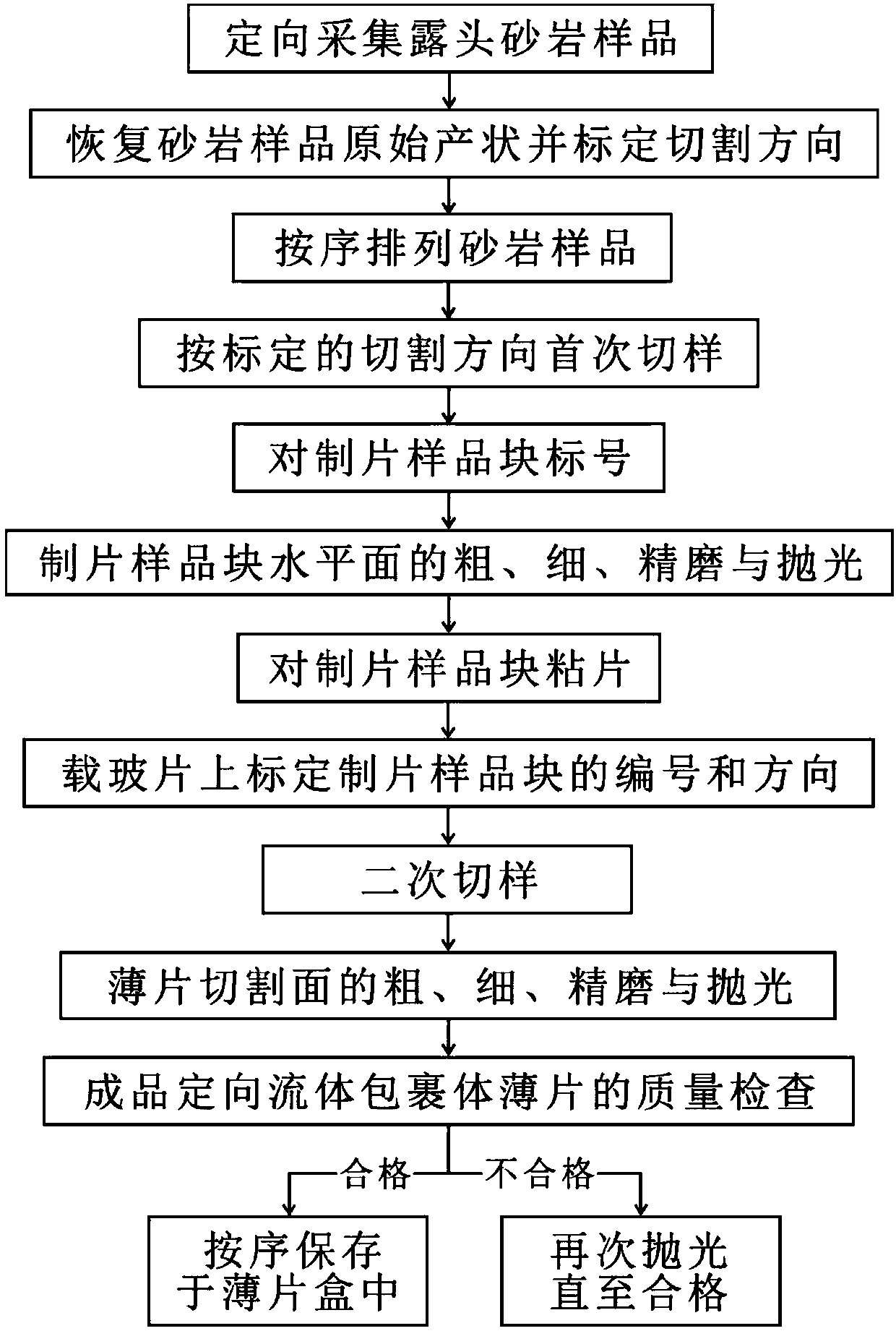

[0043] A method for making oriented fluid inclusion thin slices of outcrop sandstone samples, such as figure 1 shown, including the following steps:

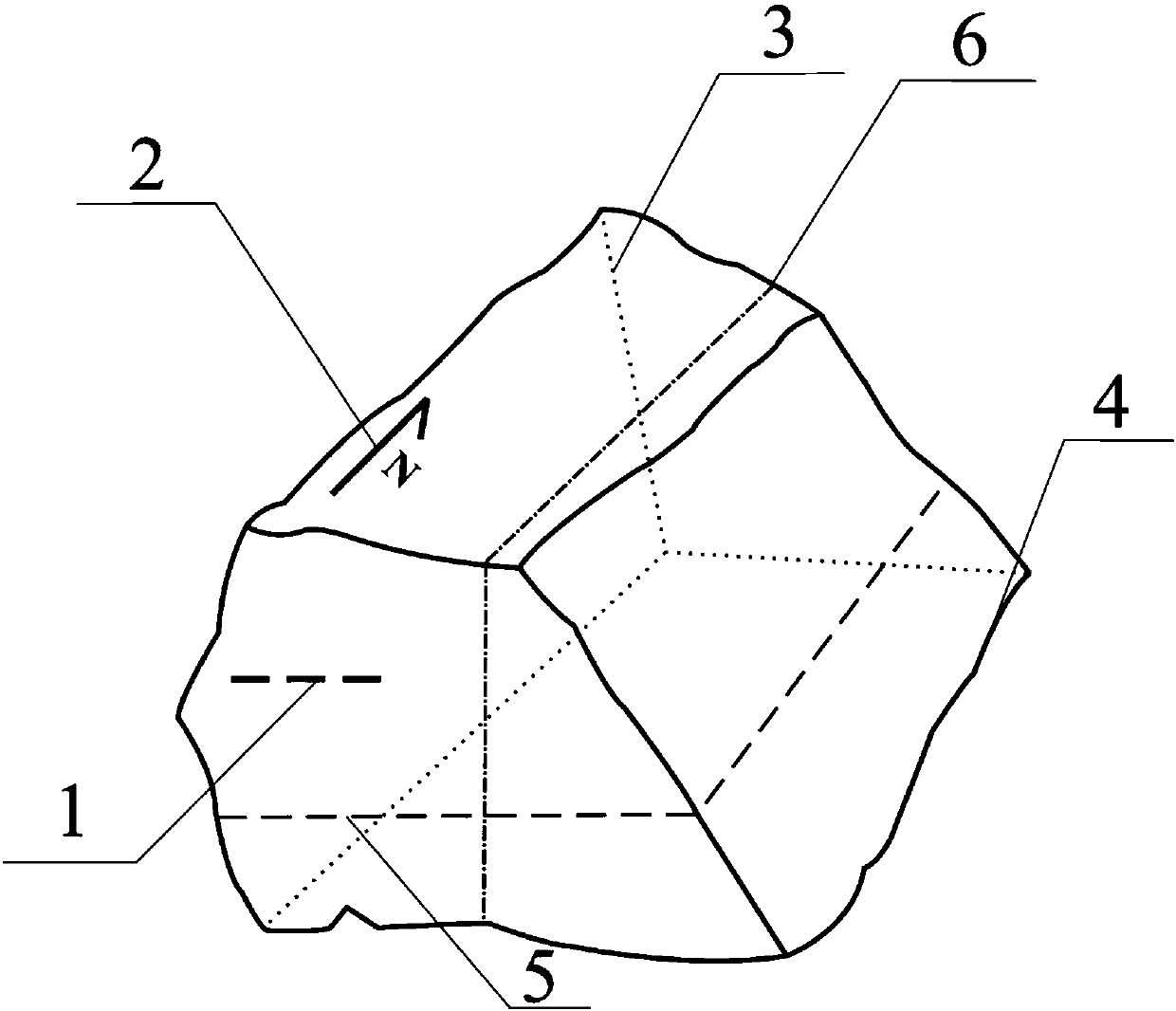

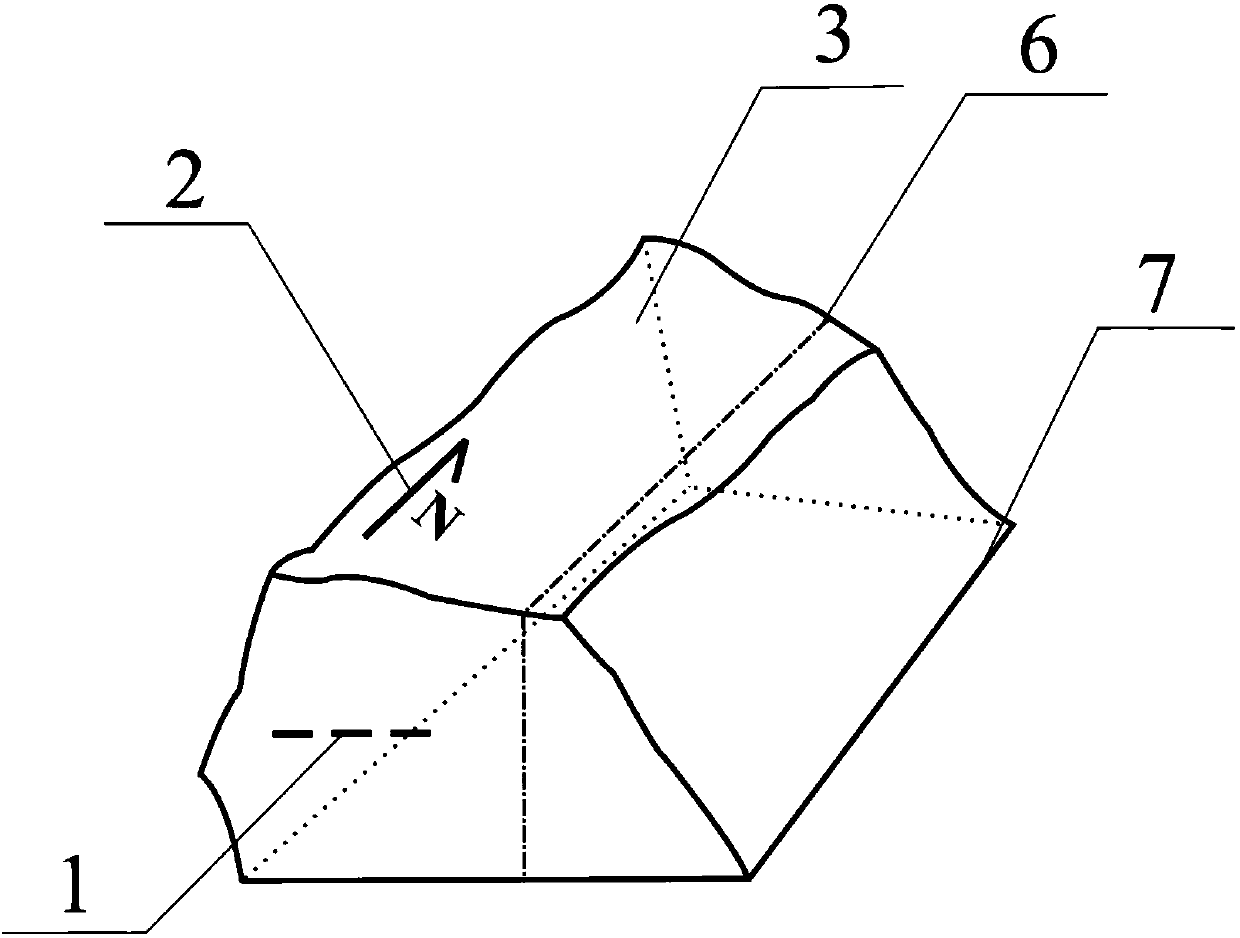

[0044] Step 1: Directional collection of outcrop sandstone samples: eg figure 2 As shown, collect sandstone samples, record the occurrence information of the sandstone strata where the sandstone samples are located and the fractures developed around them, and mark the orientation information on the sandstone samples. The orientation information includes horizontal azimuth line 1, geographic North Pole direction line 2, first top surface 3 and first bottom surface 4;

[0045] Step 2: restore the original occurrence of the sandstone sample a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com