Measurement clamp for X-CT (X ray-Computed Tomography) system

A measurement fixture and X-CT technology, which is applied to measurement devices, material analysis using radiation, material analysis using wave/particle radiation, etc., can solve problems such as inability to effectively fix tiny devices and large measurement deviations, and achieve reduction The effect of attenuation, reliable positioning, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

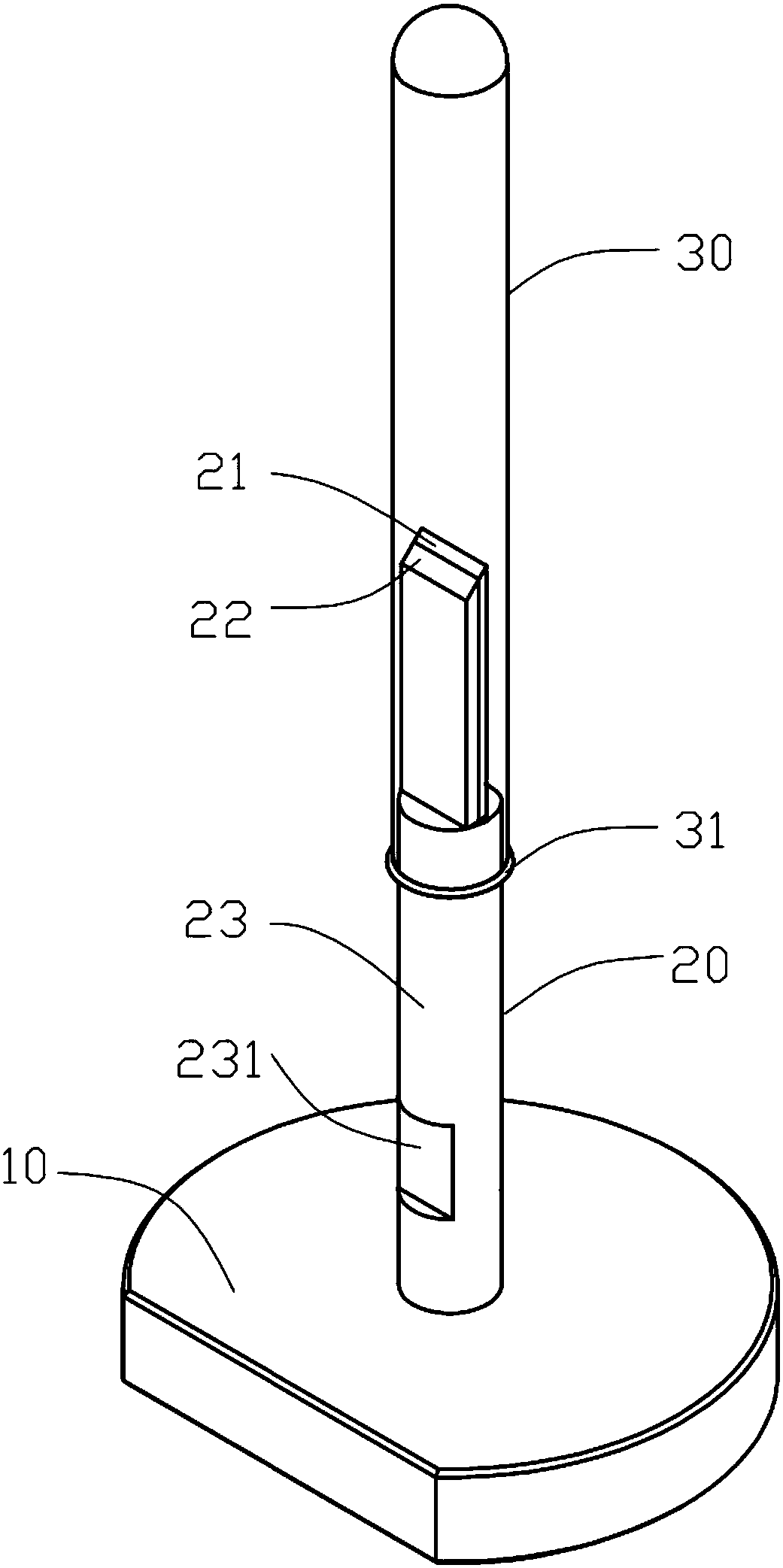

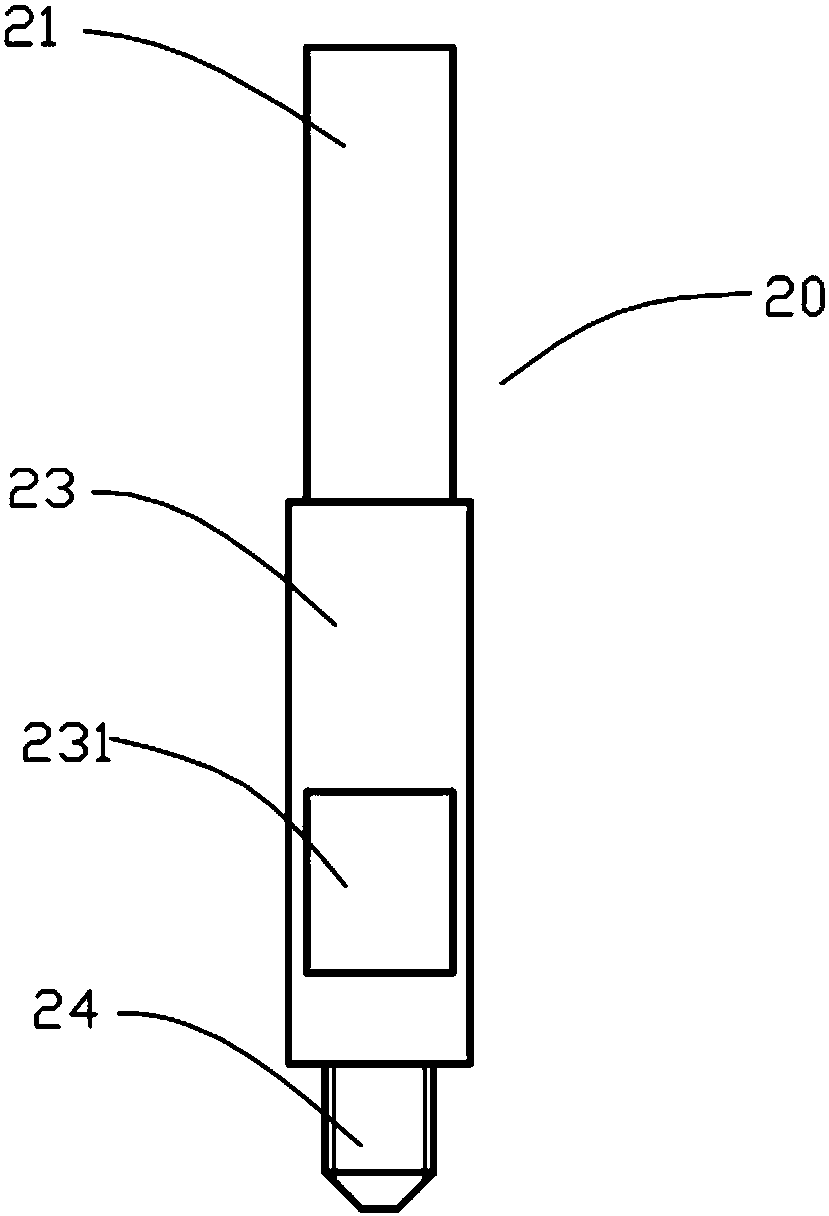

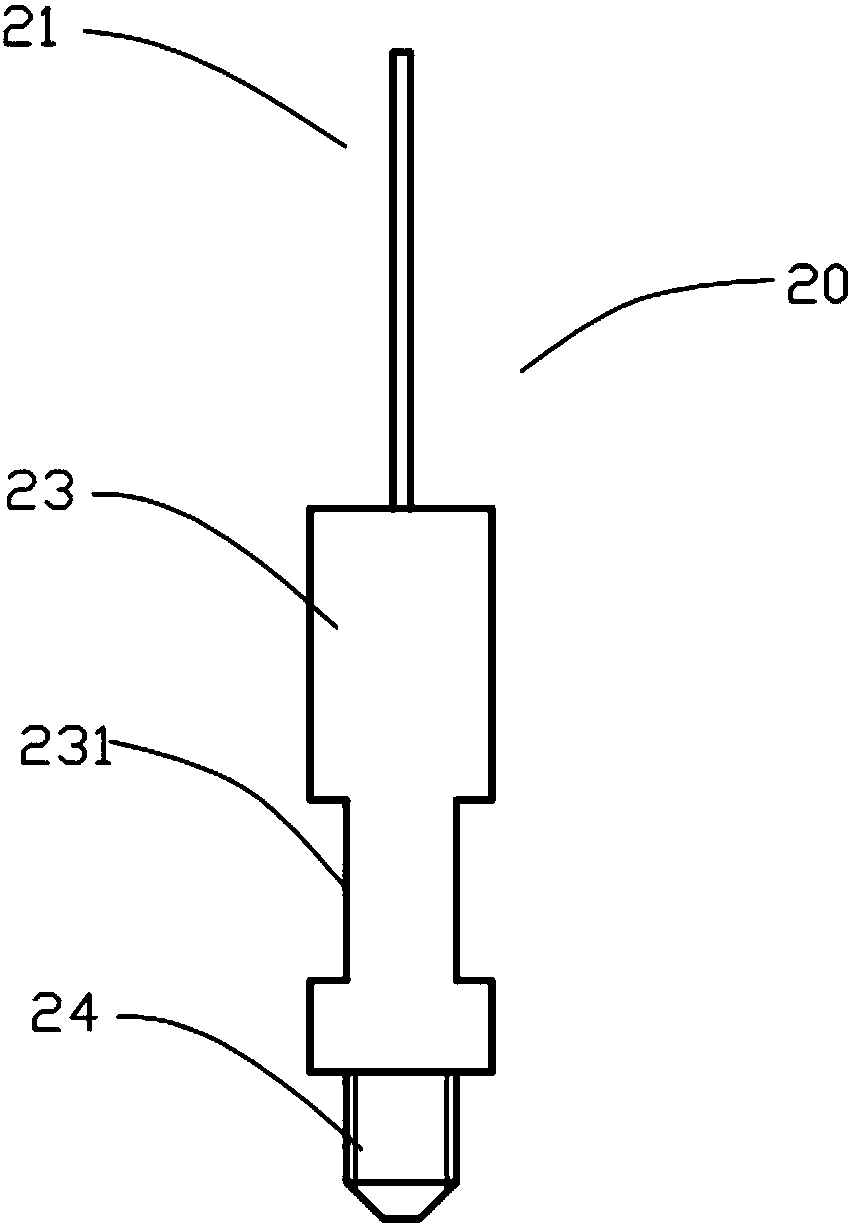

[0037] see Figure 1-Figure 5 , the center of rotation of the sample table 10 in this embodiment is provided with a threaded hole 12, and the bottom surface is provided with a positioning concave platform 11, wherein the cross-sectional structure of the positioning concave platform 11 is as follows Figure 5 As shown, this structure cooperates with the positioning points on the scanning turntable, so that the sample stage 10 can be precisely positioned on the scanning turntable, and this structure is the same as the existing fixture. Wherein the threaded hole 12 is used for connecting the slide column 20 .

[0038] The lower part of the slide column 20 is a stud 24 , which cooperates with the threaded hole 12 to tightly fix the slide column 20 on the sample stage 10 . Moreover, the rotation direction of the fastening slide column 20 is the same as the rotation direction of the scanning turntable during the test, so that the slide column 20 does not generate relative displacem...

Embodiment 2

[0054] In this embodiment, the middle part of the slide post 20 is a post 23, and the cross section of the post 23 is a closed figure surrounded by arcs and line segments. The shape of the transparent protective cover 30 is the same as that of the cylinder 23 , and the lower end of the transparent protective cover 30 is clamped on the cylinder in the middle of the slide column 20 through an interference fit from the upper end of the slide column 20 .

[0055] With the measuring jig of this embodiment, during the long-time scanning and rotating process, the positioning of the tiny device is reliable, and no relative displacement occurs with respect to the sample stage.

[0056] In summary, the measuring fixture for the X-CT system provided by the embodiment of the present invention is an effective supplement to the existing measuring fixture, and can be used for clamping and measuring micron-scale structures on tiny devices. The utility model has the advantages of simple struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com