Method and device for controlling precision treatment separation tower separating tower resin separation auxiliary backwashing water incoming regulating valve

A technology for resin separation and water inlet adjustment, applied in the direction of flow control, non-electric variable control, control/regulation system, etc., can solve the problems of increased acid-base consumption, increased cost of consumable materials, increased power consumption, etc., to achieve cost savings, The effect of boosting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

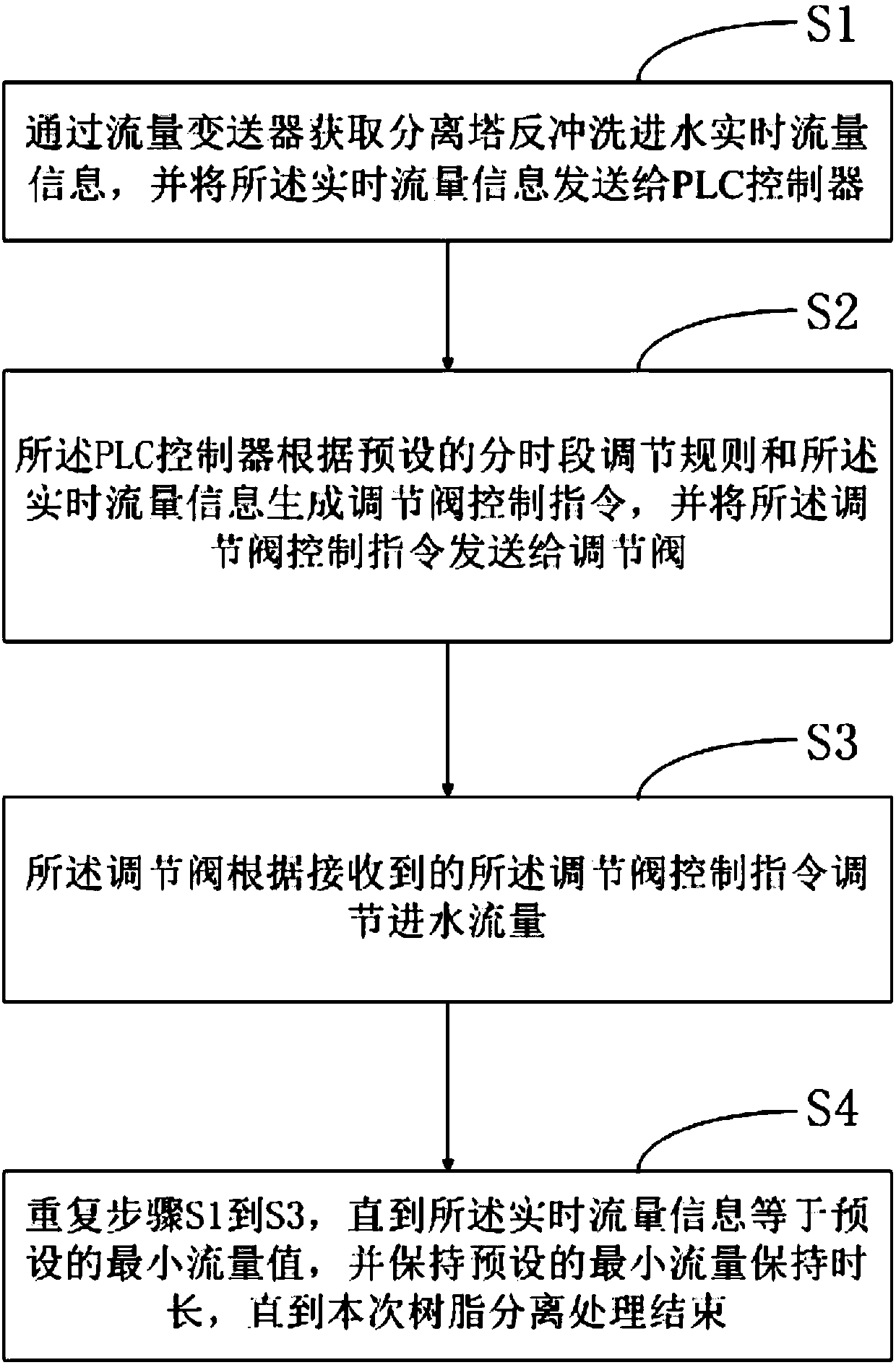

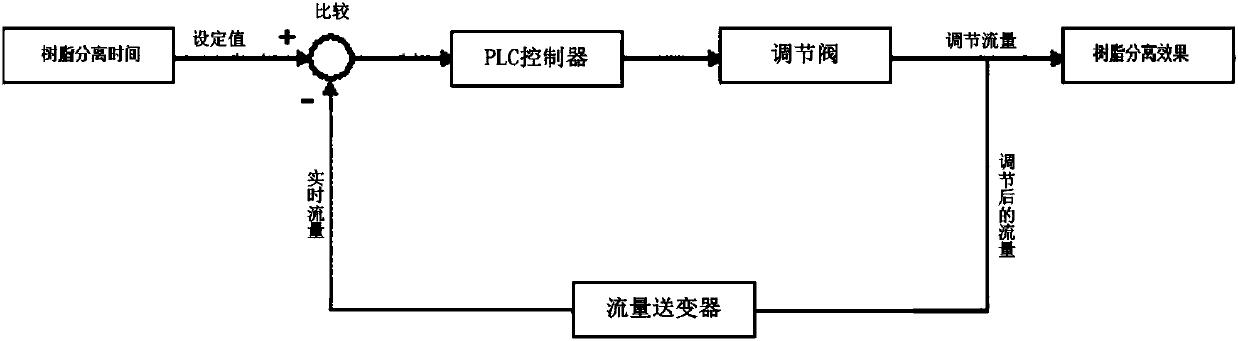

[0044] figure 1 It shows a method for controlling the resin separation auxiliary backwash inlet water regulating valve of the fine treatment separation tower provided by Embodiment 1 of the present invention, including: Step S1: Obtain the real-time flow information of the separation tower backwash inlet water through the flow transmitter, and Send the real-time flow information to the PLC controller; Step S2: The PLC controller generates a regulating valve control instruction according to the preset period-by-time regulation rule and the real-time flow information, and sends the regulating valve control instruction to Regulating valve; Step S3: The regulating valve adjusts the water flow according to the received control command of the regulating valve; Step S4: Repeat steps S1 to S3 until the real-time flow information is equal to the preset minimum flow value, and keep The preset minimum flow rate is maintained until the end of the resin separation process. figure 2 The c...

Embodiment 2

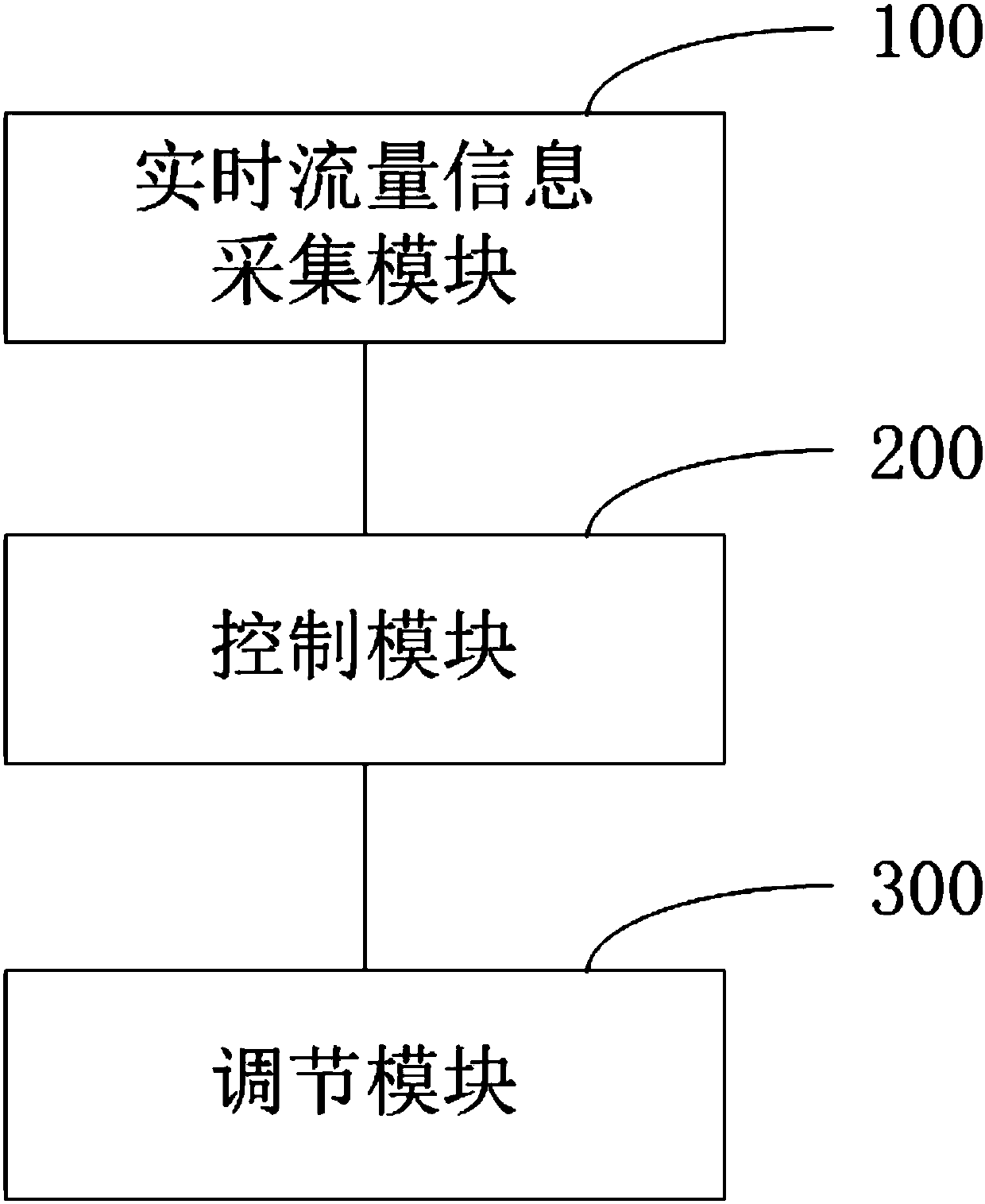

[0050] image 3 It is a schematic structural diagram of a control device for a fine treatment separation tower resin separation auxiliary backwash water inlet regulating valve provided in Embodiment 2 of the present invention. The device includes: a real-time flow information acquisition module 100, which is used to obtain real-time flow information, and send the real-time flow information to the control module; the control module 200 is configured to generate a regulating valve control instruction according to the preset time-period regulation rule and the real-time flow information, and send the regulating valve control instruction For the adjustment module; the adjustment module 300 is configured to control the adjustment valve to adjust the inflow flow according to the received control instruction of the adjustment valve.

[0051] In general, the preset time-period adjustment rule is: at the beginning of each resin separation process, a control valve control command to adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com