A kind of ultrasonic wire bonding ultrasonic frequency self-adjustment method

A wire bonding, ultrasonic technology, applied in control/adjustment systems, mechanical oscillation control, instruments, etc., can solve the problem of natural frequency deviating from ultrasonic frequency, can not reach, etc., to achieve the effect of improving the bonding power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

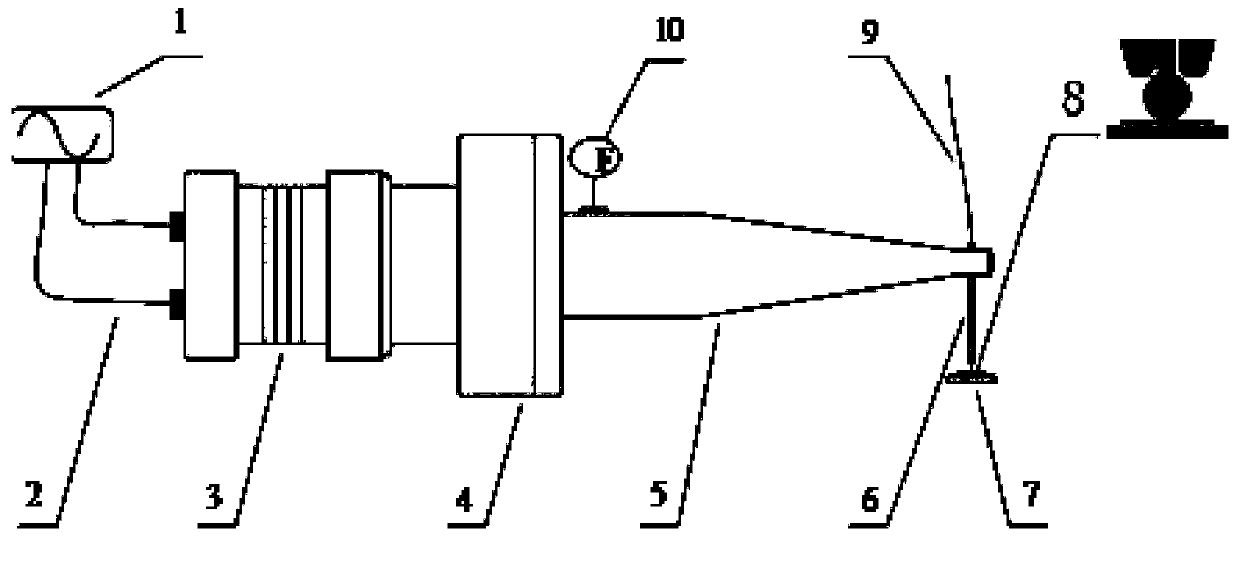

[0025] figure 1 It is the schematic diagram of the ultrasonic-bonding system of the existing ultrasonic bonding process, which consists of an ultrasonic generator 1, an ultrasonic input device 2, a piezoelectric transducer 3, a mounting sleeve 4, a horn 5, and a bonding tool 6 , bottom pad 7, bonding pad 8, metal lead 9, pressure device 10, workbench and static pressure generating mechanism. The principle of the bonding process can be described in the following four steps: ① Ultrasonic generator 1 generates high-frequency ultrasonic energy; ② Ultrasonic energy enters piezoelectric transducer 3 and is converted by piezoelectric transducer (reverse pressure of piezoelectric crystal Electric effect) into high-frequency mechanical vibration energy (frequency is generally 65kHz or higher, here determined according to the natural frequency of the transducer system); ③High-frequency mechanical vibration is transmitted to the tip of the bonding tool 6 through the energy concentrator, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com