Online glue applying device for fiber ring winding

A technology of optical fiber ring and gluing, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven internal curing stress, inability to guarantee the uniformity of gluing, and affect product performance, etc., and achieve good market application Prospect, good operation, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

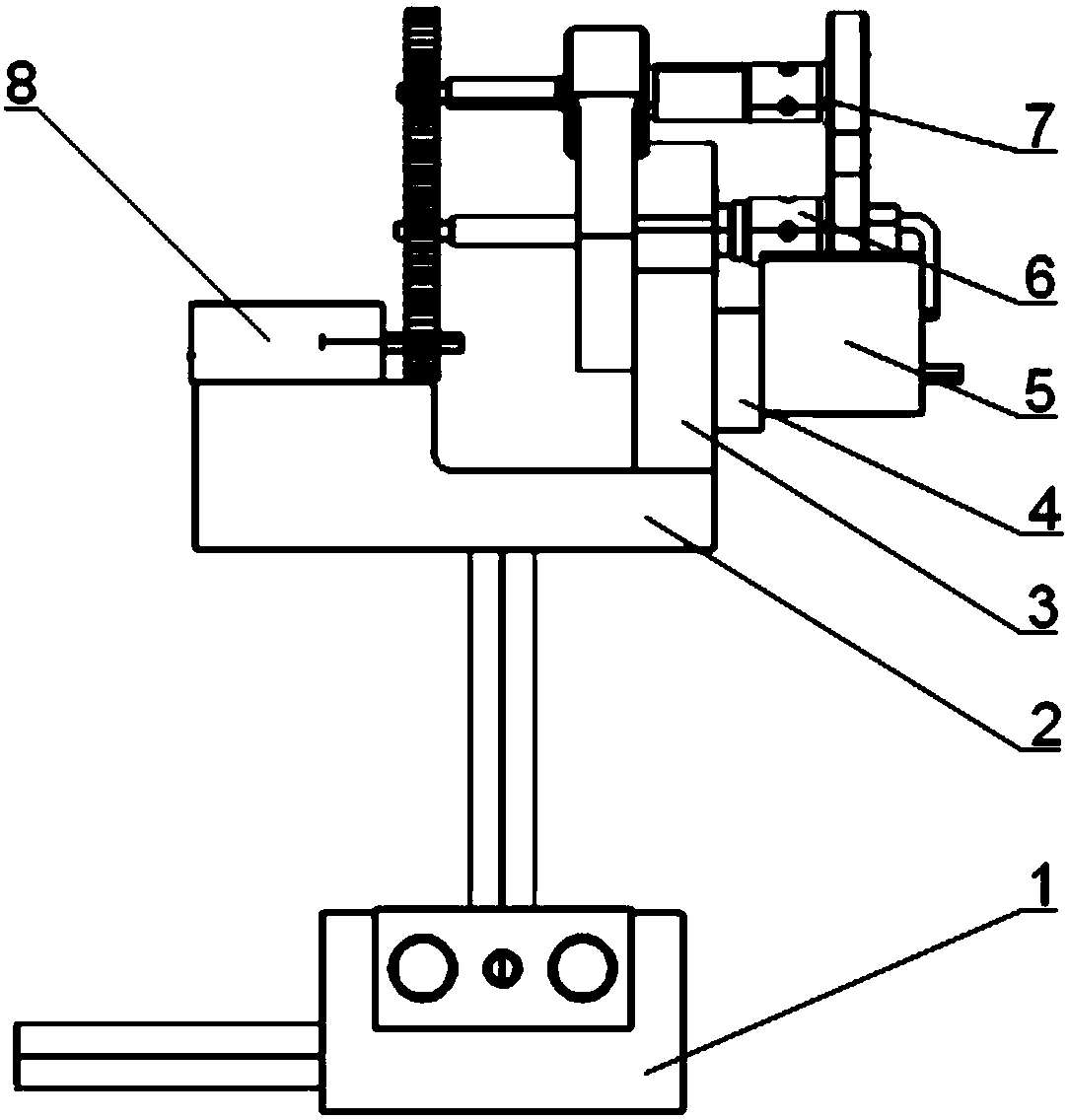

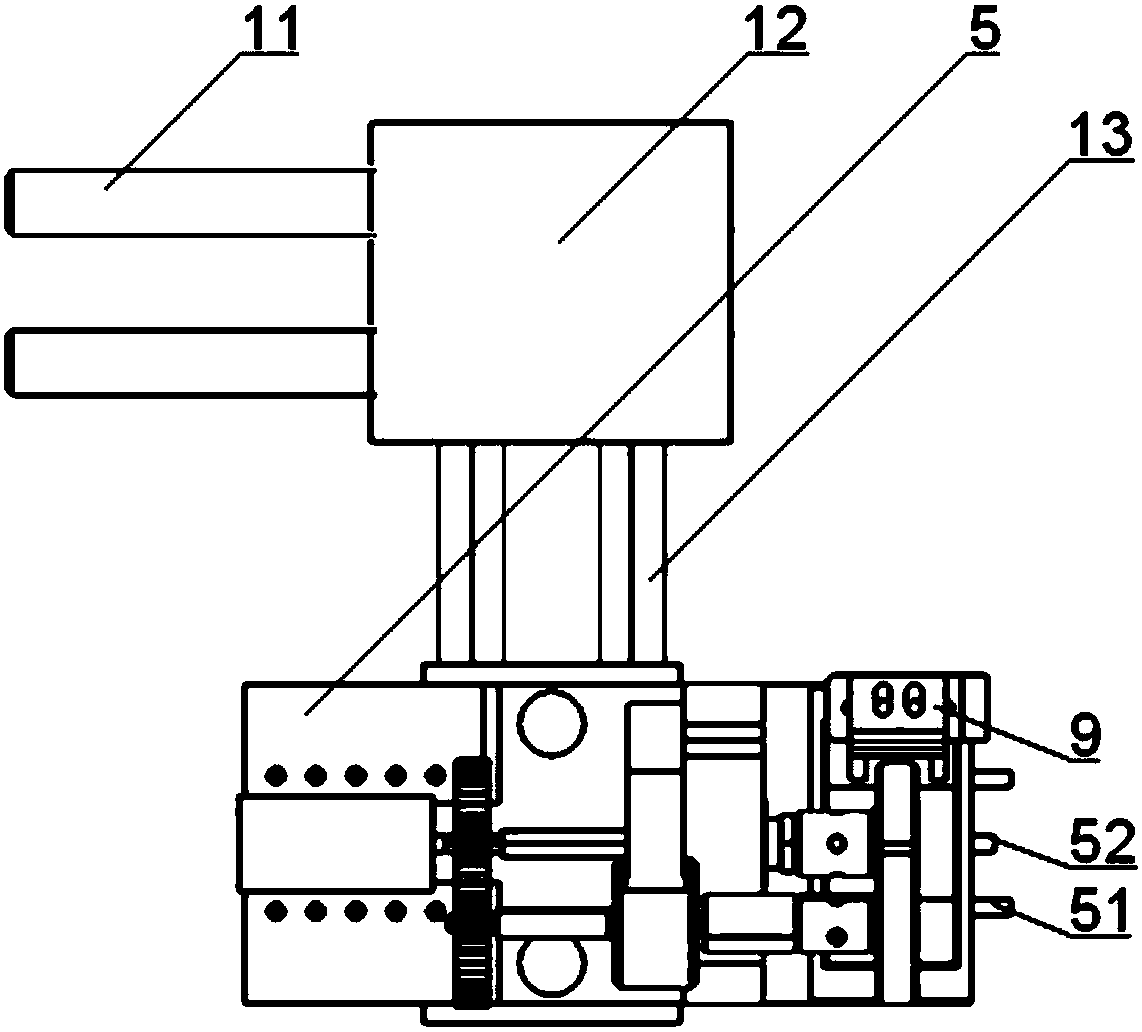

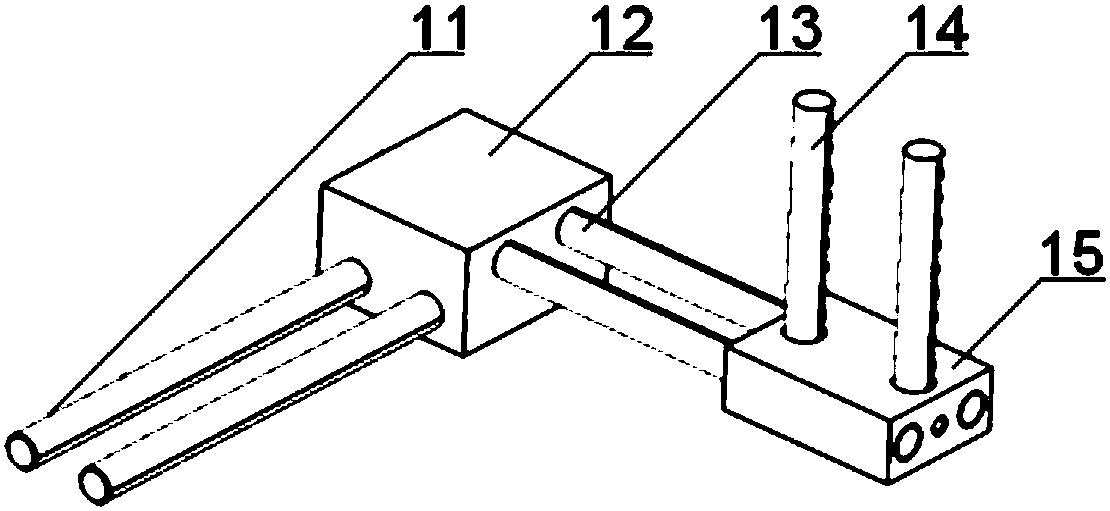

[0036] Such as Figure 1~2 As shown, an optical fiber ring winding online gluing device includes a bracket 1, a base 2, a base plate 3, a baffle plate 4, a glue pool 5, a gluing mechanism 6, a gluing mechanism 7, a motor 8 and a scraper 9; the base 2 A solid cube structure is adopted, and the base 2 is installed on the support 1 for limiting the translational freedom of the base 2; the motor 8 for driving the gluing mechanism 6 and the base plate 3 for supporting the gluing mechanism 6 and the gluing mechanism 7 are both Installed on the base 2; the gluing mechanism 7 cooperates with the scraper 9 and evenly coats the glue in the glue pool 5 on the optical fiber ring through the gluing mechanism 6, and there is a spacer between the glue pool 5 and the base plate 3 Heat baffle4.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com