Automatic bending and welding all-in-one machine for reinforcing steel bars

An all-in-one machine and steel bar technology, applied in welding equipment, resistance welding equipment, applications, etc., can solve problems such as poor adaptability and low efficiency, and achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

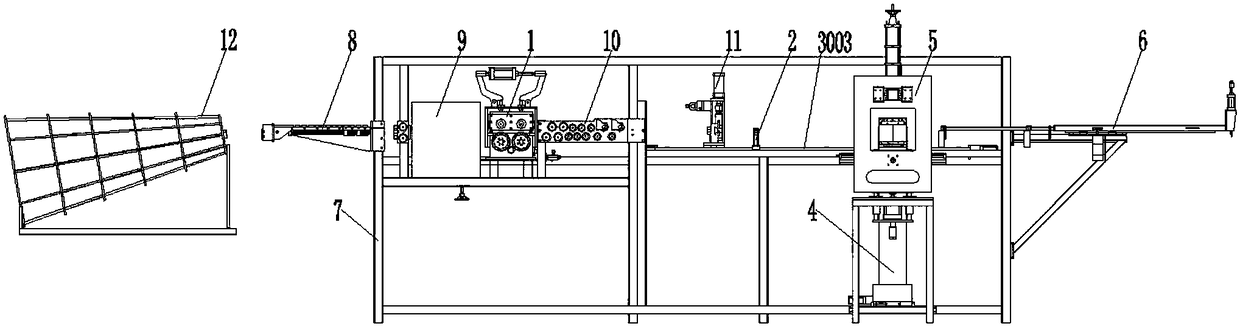

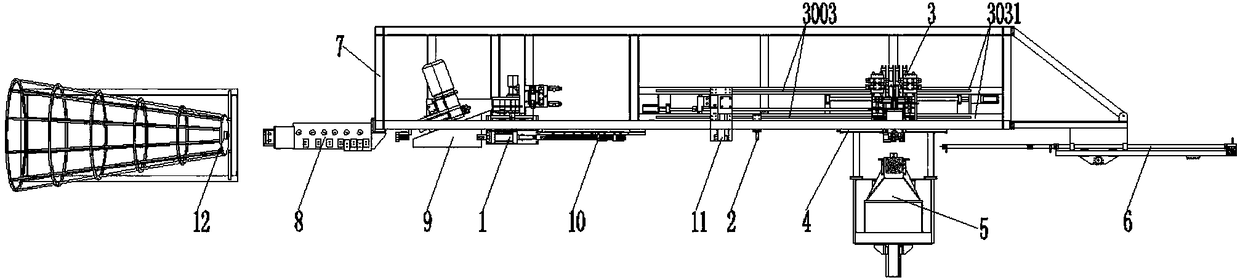

[0073] see figure 1 , figure 2 , a steel bar automatic bending and welding machine, including a base frame 7, and the base frame 7 is horizontally provided with a primary straightening device 8, a two-way synchronous derusting device 9, a feeding device 1, a secondary straightening device 10, and a cutting device 11 , Feeding auxiliary support device 2, hoop bending device 3 and automatic unloading device 6; also includes a preliminary calibration device 12, the preliminary calibration device 12 is a hollow tapered steel skeleton structure;

[0074] The base frame 7 includes two horizontal parallel and opposite square steel pipe bases 3031, and the two square steel pipe bases 3031 are provided with horizontal slide rails I3003,

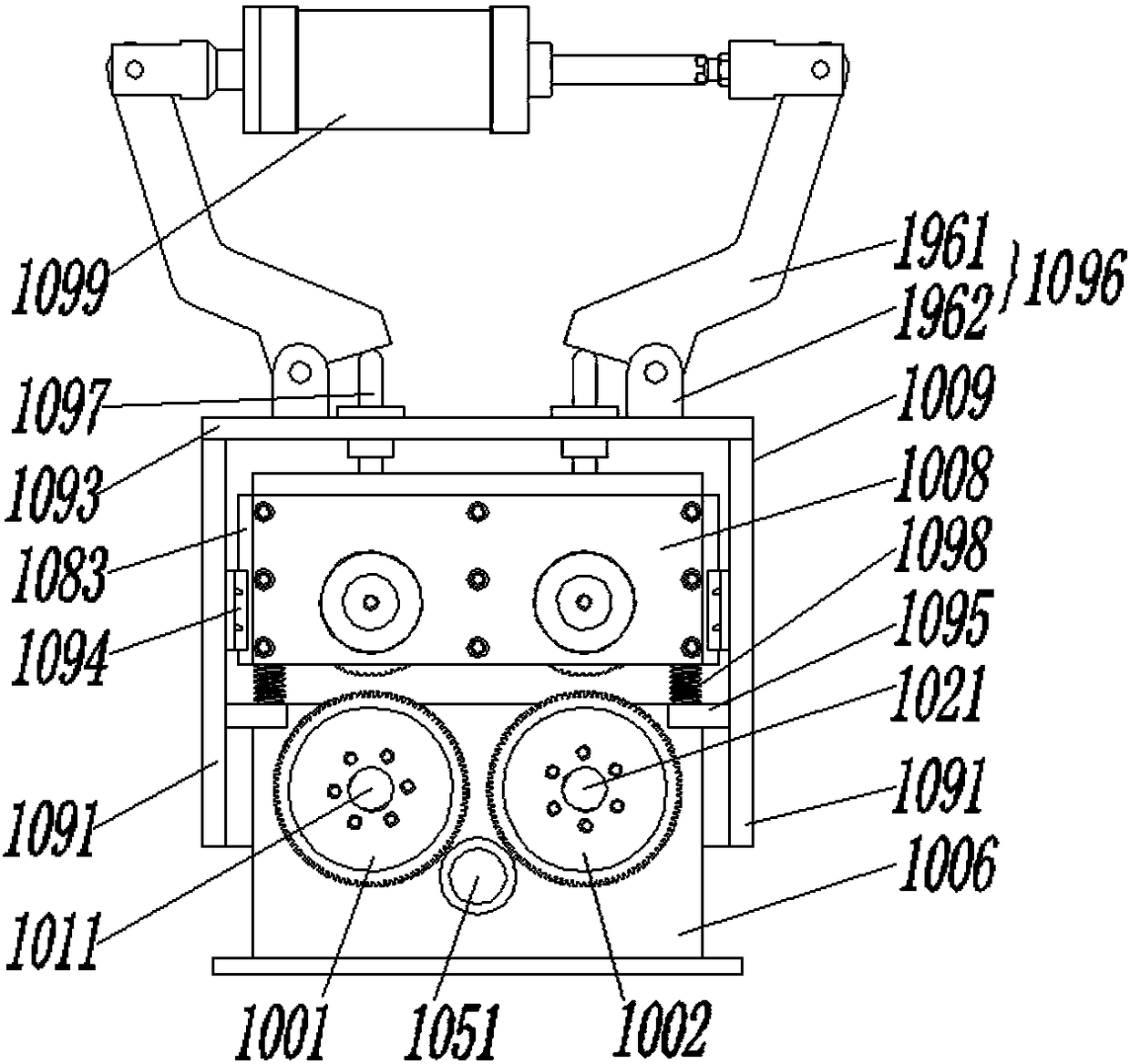

[0075] The feeding device 1 is used for traction and feeding of steel bars so that the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com