Assembling device and assembling method of automobile vacuum booster and brake master cylinder

A technology of vacuum booster and brake master cylinder, which is applied in measuring devices, instruments, assembly machines, etc., can solve the problems of time-consuming, error, and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

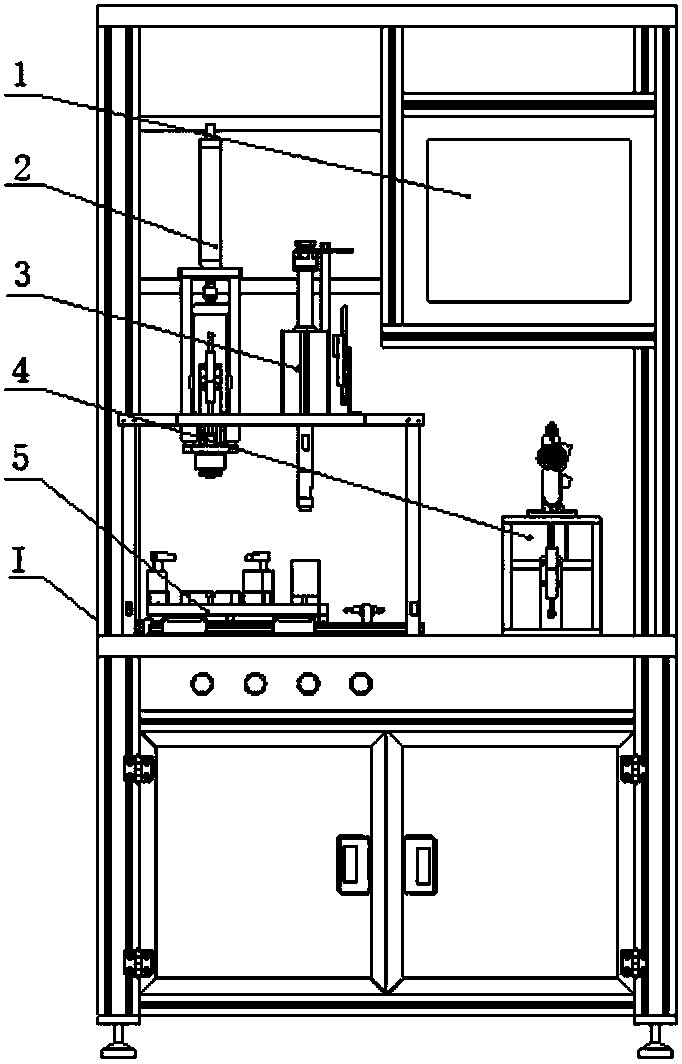

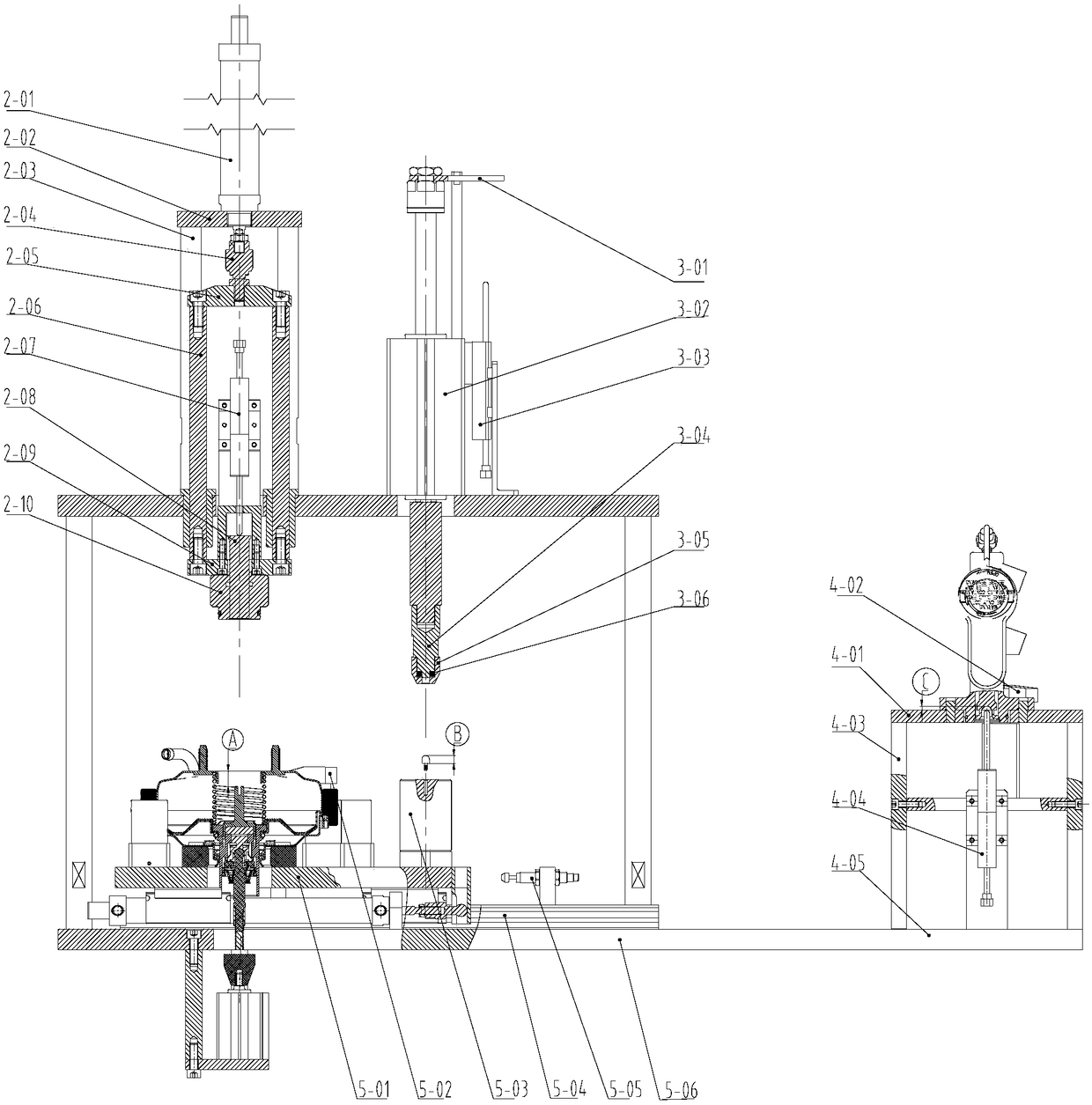

[0081] Such as figure 1 with figure 2 As shown, the assembly device of the automobile vacuum booster and the brake master cylinder includes an assembly frame body I, and the assembly frame body I is provided with a press-fit table, a PLC control device 1, and a distance measurement between the end face of the vacuum booster output rod and the end face of the rear housing. Device 2, output rod head length measuring device 3, brake master cylinder first piston depth measuring device 4, sliding table device 5, measuring button, press-fit button and power management device.

[0082] In the assembly device of the automobile vacuum booster and brake master cylinder described in this embodiment, the distance measuring device 2 between the end face of the output rod of the vacuum booster and the end face of the rear housing is connected to the PLC control device 1 for accurately measuring the The distance from the end face of the output rod of the vacuum booster to the installation en...

Embodiment 2

[0132] On the basis of the technical solution described in embodiment 1, the assembly frame body 1 of the assembly device of the automobile vacuum booster and the brake master cylinder is also provided with a retest button, and the retest button is connected to the PLC control device 1. The power management device is connected to the measurement button, the press-fit button, the retest button and the PLC control device 1 to provide power guarantee for the automatic press-fit process.

[0133] Set the retest button and add a retest link.

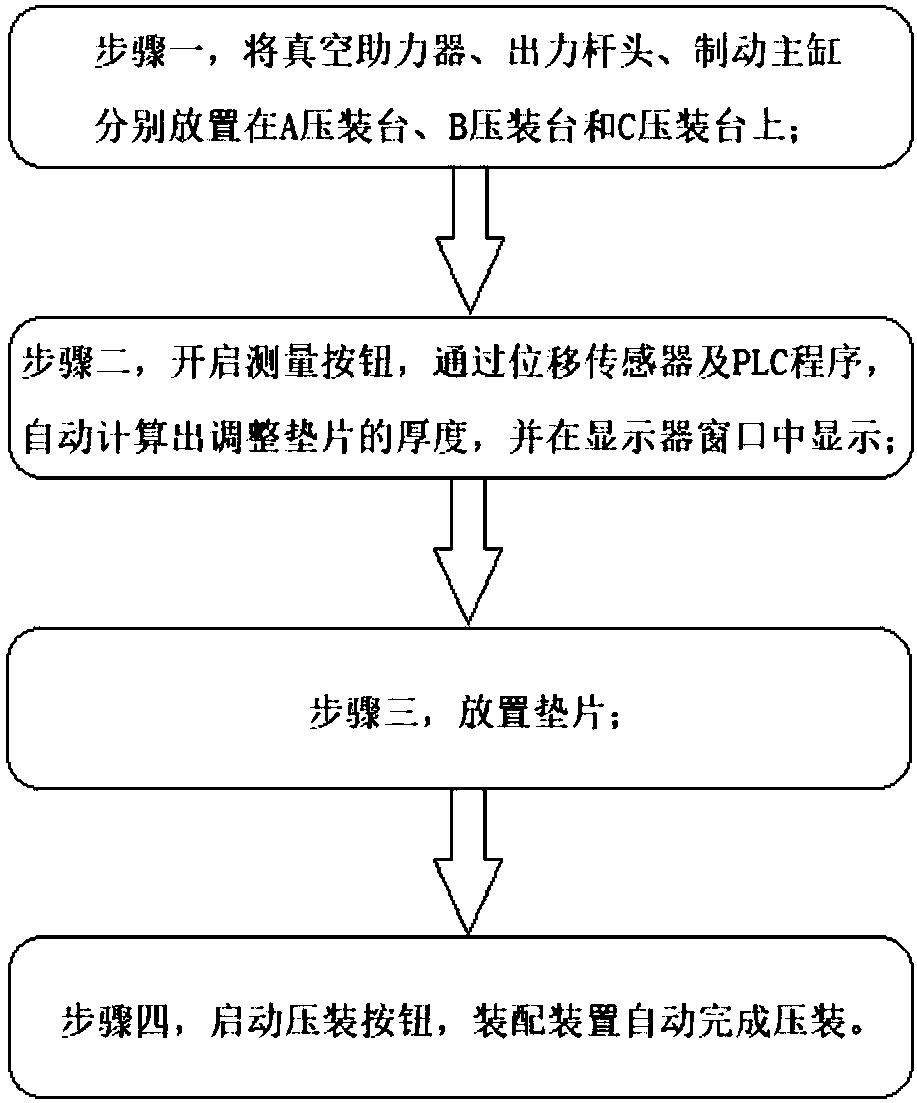

[0134] Such as Figure 4 As shown, a retesting step is added between steps 2 and 3 of the assembly method of the automobile vacuum booster and brake master cylinder: place the vacuum booster, the output rod head, and the brake master cylinder on three press-fitting stations respectively. On A, B, and C, turn on the measurement button, automatically calculate the thickness of the adjusting gasket through the displacement sensor and the PLC pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com