Auxiliary supporting device for milling machine

An auxiliary support and milling machine technology, applied in the direction of milling machine equipment, milling machine equipment details, large fixed members, etc., can solve the problems of inconvenient clamping of workpieces, and achieve the effect of stable force and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

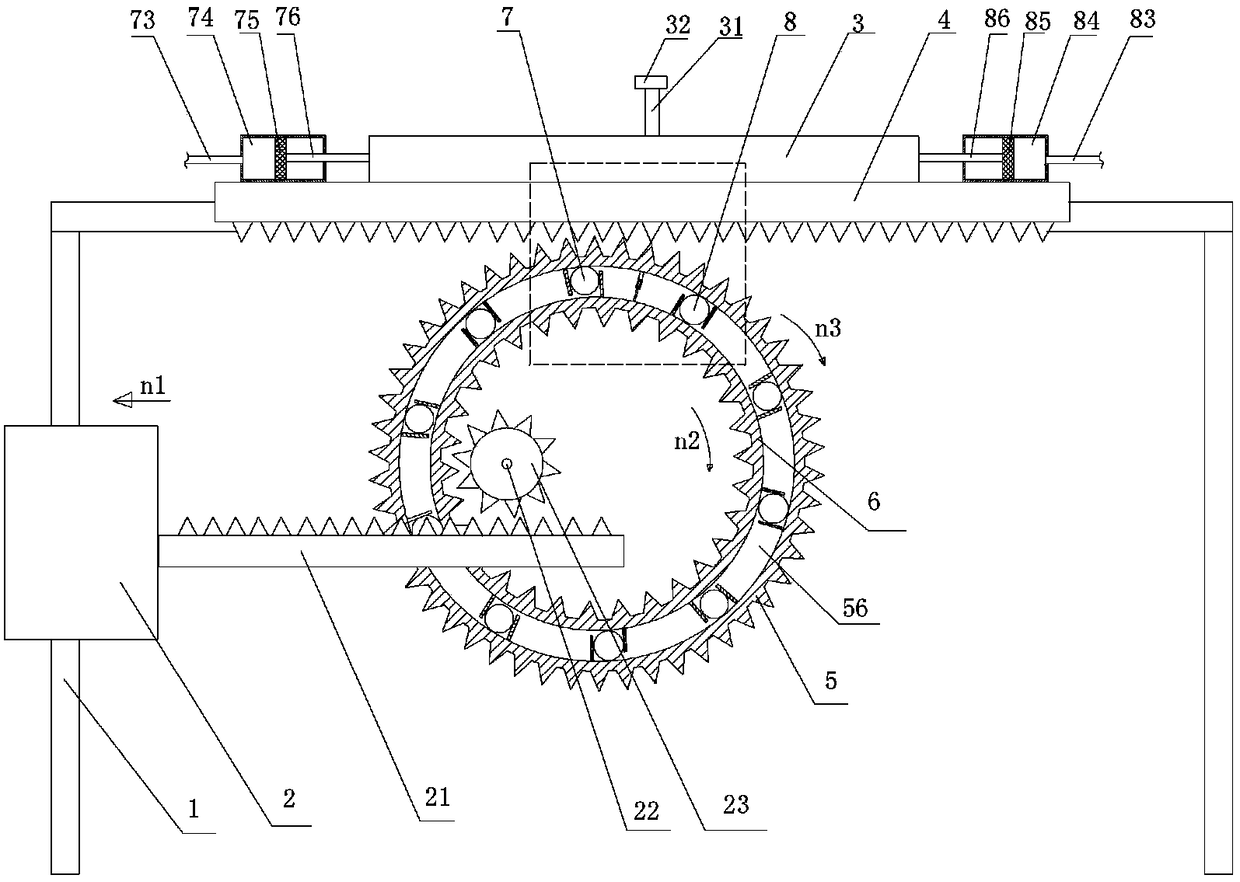

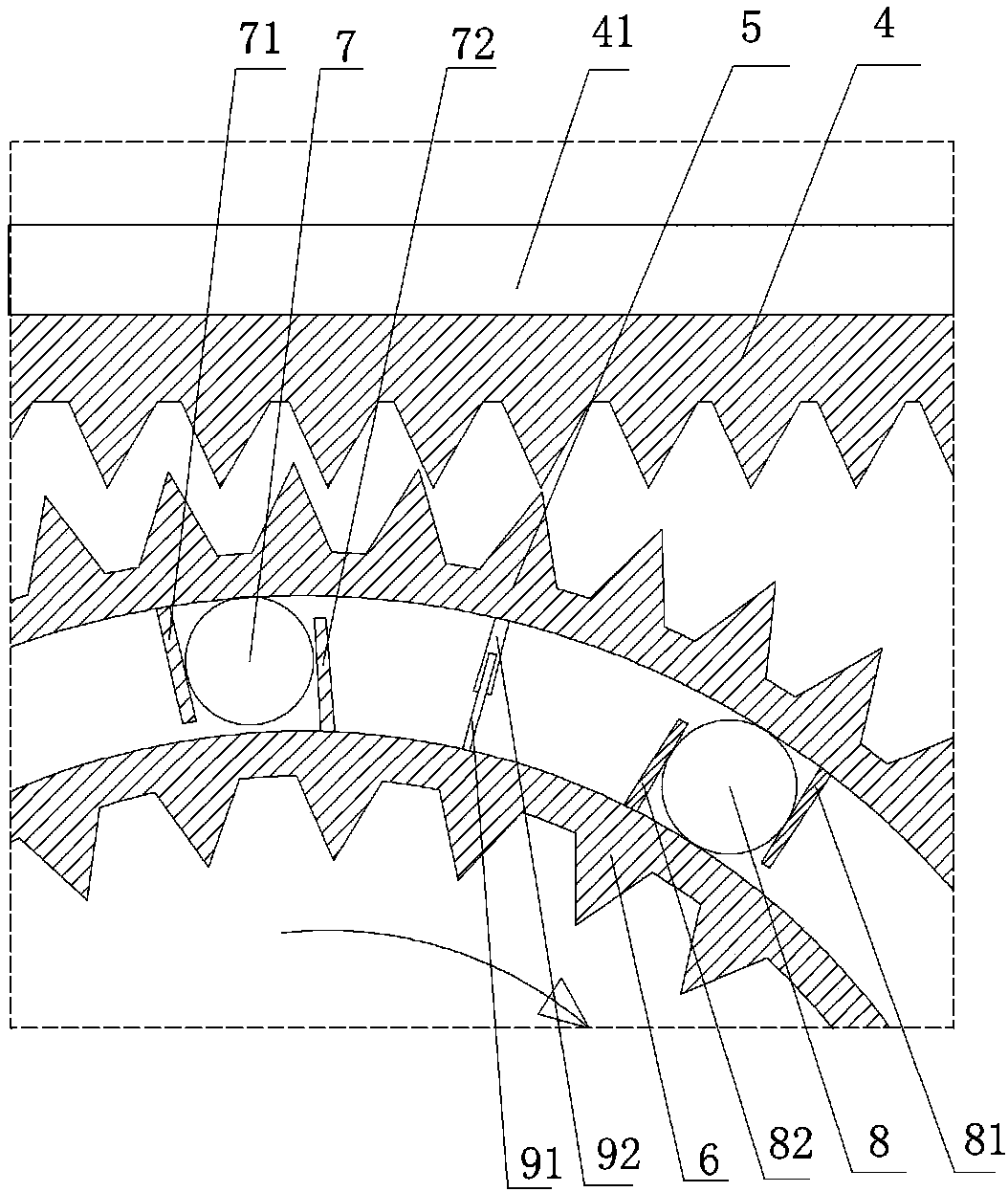

[0023] The reference signs in the accompanying drawings of the description include: supporting stand 1, workbench 2, second rack 21, first rotating shaft 22, gear 23, adjustment plate 3, support rod 31, positioning groove 32, first rack 4 , electromagnet 41, outer ring gear 5, detection cavity 56, inner ring gear 6, first air bag 7, first outer baffle 71, first inner baffle 72, first hose 73, first piston chamber 74, First piston 75, first piston rod 76, second air bag 8, second outer baffle 81, second inner baffle 82, second hose 83, second piston cavity 84, second piston 85, second piston The rod 86 , the second conductive sheet 91 , and the first conductive sheet 92 .

[0024] Such as figure 1 As shown, the milling machine auxiliary support device of this embodiment includes a support stand 1, a hollow first rack 4 is horizontally slidably disposed on the support stand 1, and an adjustment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com