Non-setting adhesive labeller label placing roller

An adhesive labeling machine and roller technology, which is applied in the field of labeling rollers of self-adhesive labeling machines, can solve the problems of uncontrollable roller rotation process, inability to run synchronously with production, and inability to achieve accurate label placement, etc., so as to avoid labels from slipping off. , Simple structure and firm fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

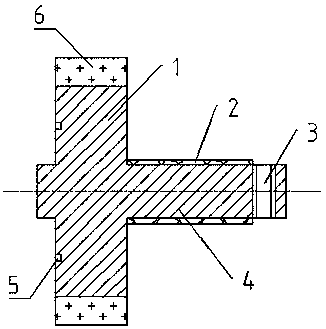

[0010] Such as figure 1 As shown, the present invention adopts the following technical solutions to realize: the labeling roller of this kind of self-adhesive labeling machine includes a fixed shaft 1, an anti-skid sheath 2, a timing belt 3, a rolling shaft 4, a positioning groove 5 and a fixed limit device 6. The central axes of the fixed shaft 1 and the rolling shaft 4 are perpendicular to each other. There is a timing belt 3 inside the rolling shaft 4. The central axis of the timing belt 3 is perpendicular to the central axis of the rolling shaft 4. A fixed limiter is set at both ends of the fixed shaft 1. Positioning device 6, the end surface of the fixed shaft 1 away from the rolling shaft 4 is provided with four positioning grooves 5, the four positioning grooves 5 are evenly distributed on the same circumference, and the outer surface of the rolling shaft 4 close to the fixed shaft 1 is covered With non-slip sheath2.

[0011] As a preferred solution of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com