A powder conductivity test equipment

A technology for testing equipment and conductivity, which is applied to parts of electrical measuring instruments, measuring devices, and measuring electrical variables. The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

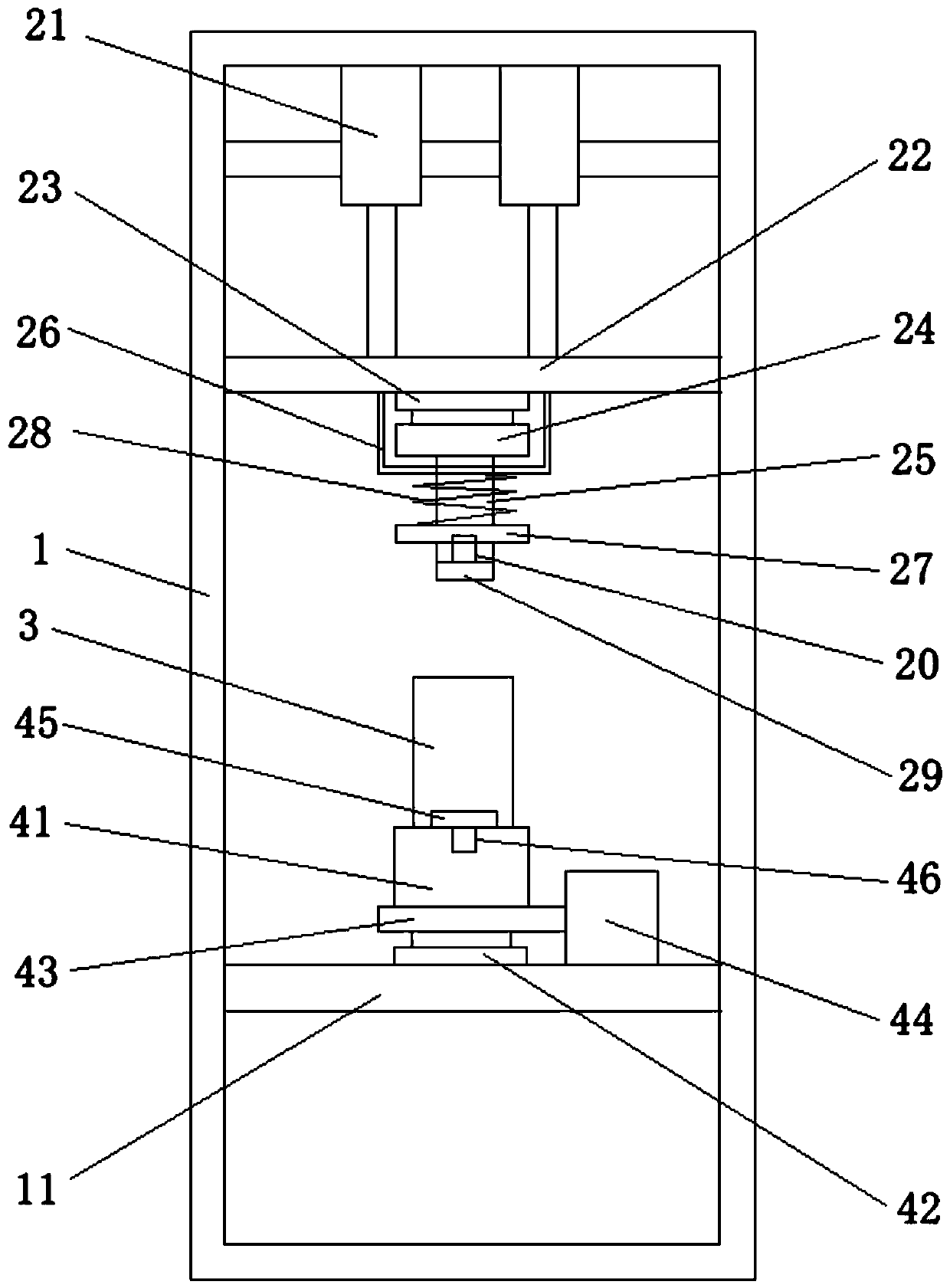

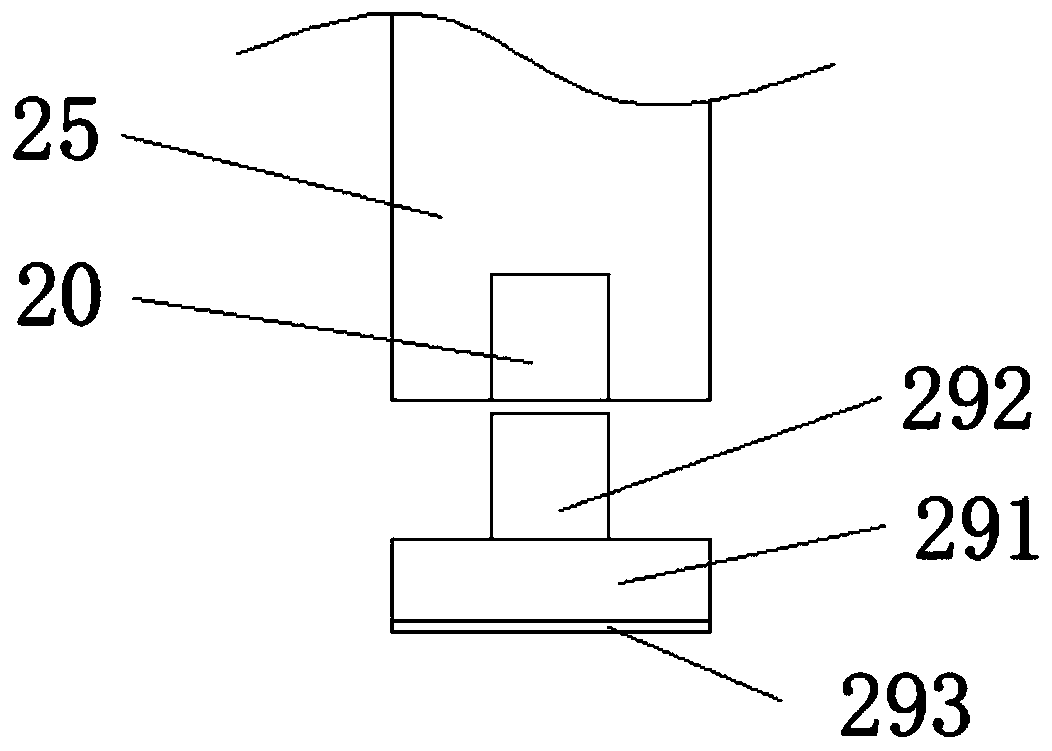

[0034] This embodiment provides a powder conductivity testing device. By designing a structure capable of driving the material tube to vibrate, the powder in the material tube is vibrated evenly, thereby improving the uniformity of the powder density and improving the measurement accuracy.

[0035] The powder conductivity testing equipment provided in this embodiment includes a bracket 1, a pressure applying mechanism, a material pipe 3 and a pressure bearing mechanism, the pressure bearing mechanism is arranged at the lower part of the bracket 1, and the material pipe 3 is installed on the bearing On the pressure mechanism, the pressure applying mechanism is arranged on the upper part of the support 1, the material pipe 3 is used to accommodate the powder whose conductivity is to be tested, and the pressure applying mechanism is used to apply a test pressure to the material pipe 3.

[0036] Wherein, the support 1 is a frame structure, including an upper connection plate, a low...

Embodiment 2

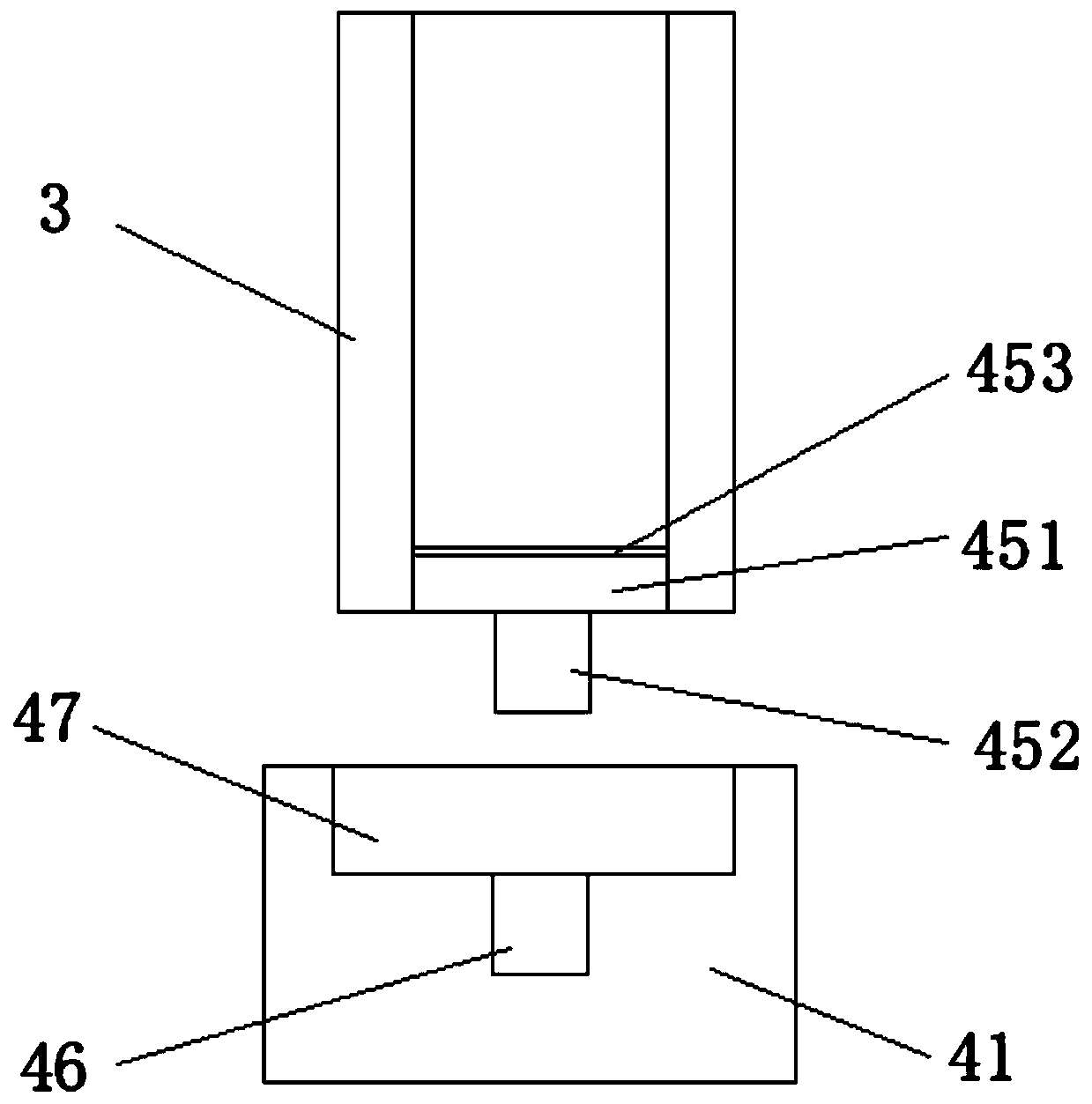

[0046] This embodiment provides a powder conductivity testing device. On the one hand, the powder in the material tube is vibrated evenly by designing a structure that drives the material to vibrate, improving the uniformity of the powder density and improving the measurement accuracy; on the other hand, in conjunction with The deformation layer is set on the upper conductive pressure head and the lower conductive pressure head in contact with the powder, and the contact area between the upper conductive pressure head and the lower conductive pressure head and the powder is increased through the deformation layer, and the contact area between the upper conductive pressure head and the lower conductive pressure head and the powder is improved. The contact effect can avoid measurement errors caused by poor contact, thereby further improving the measurement accuracy.

[0047] The powder conductivity testing equipment provided in this embodiment includes a bracket 1, a pressure app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com