A grain refinement method of lead-tin alloy casting structure

A technology of grain refinement and alloy casting, applied in the direction of improving process efficiency, can solve the problems of complex equipment, composition segregation, high cost, prevent rapid decay, improve mechanical properties and thermal fatigue properties, and achieve fine grain structure. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

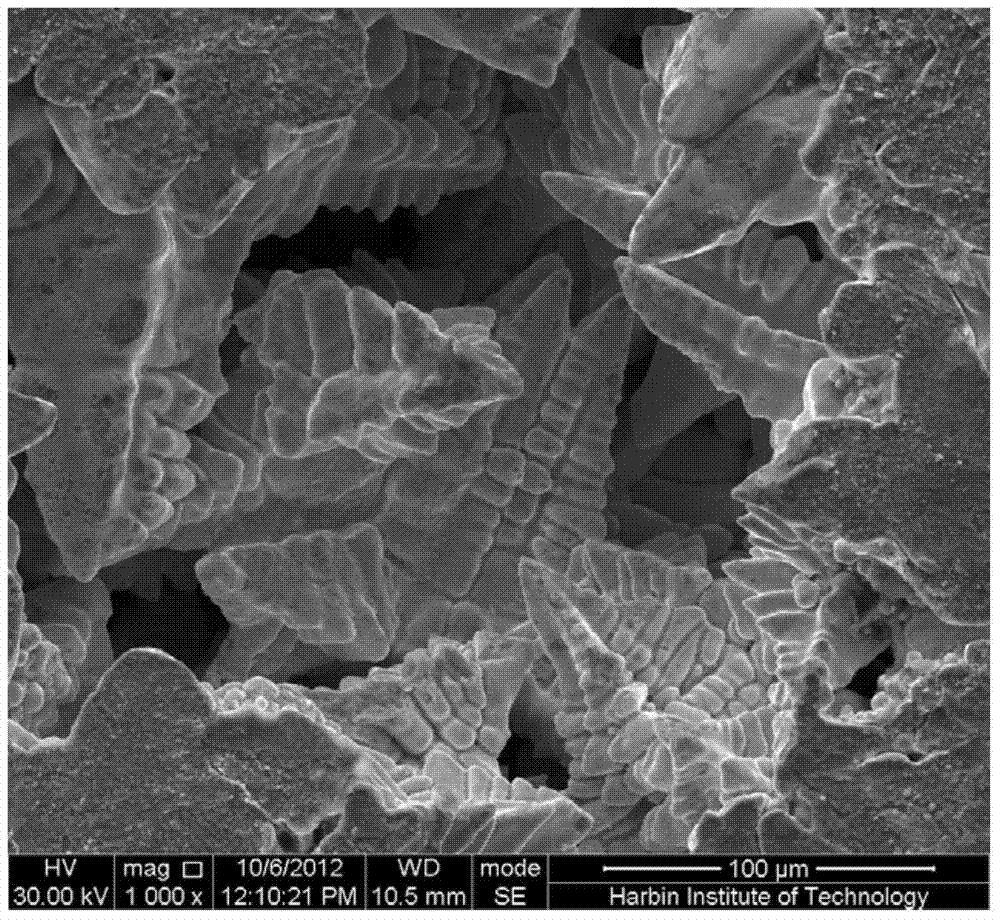

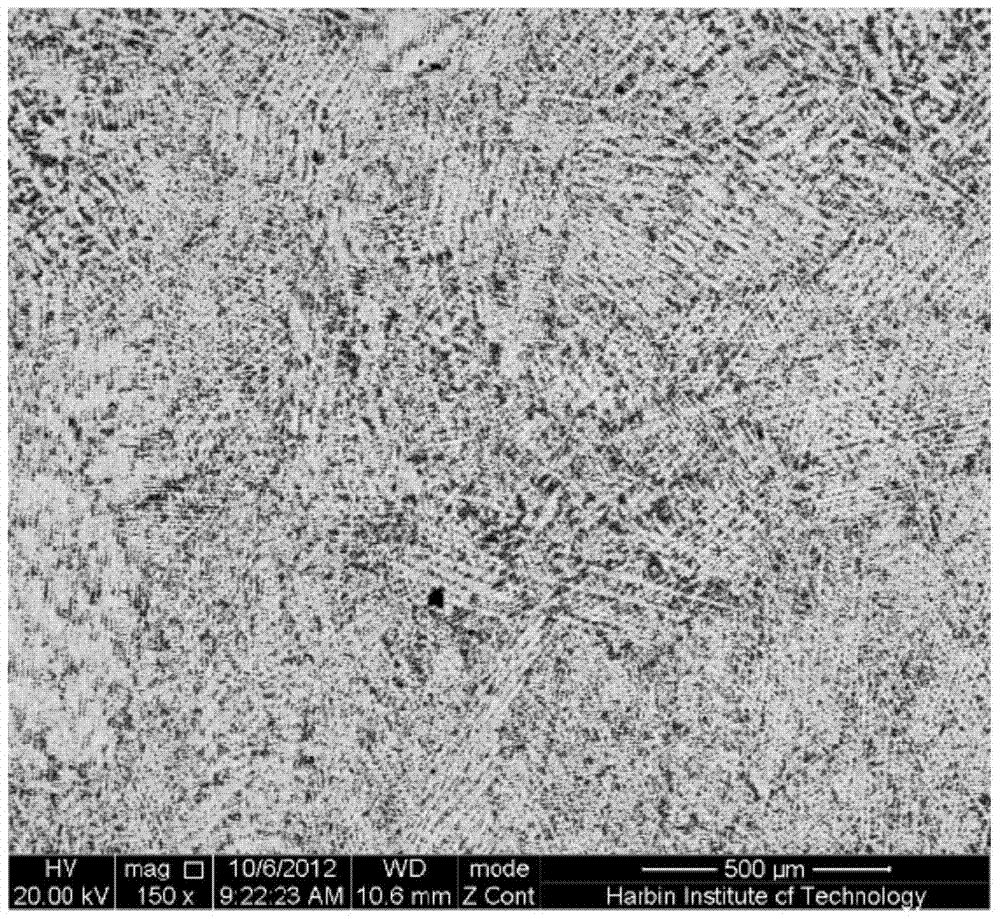

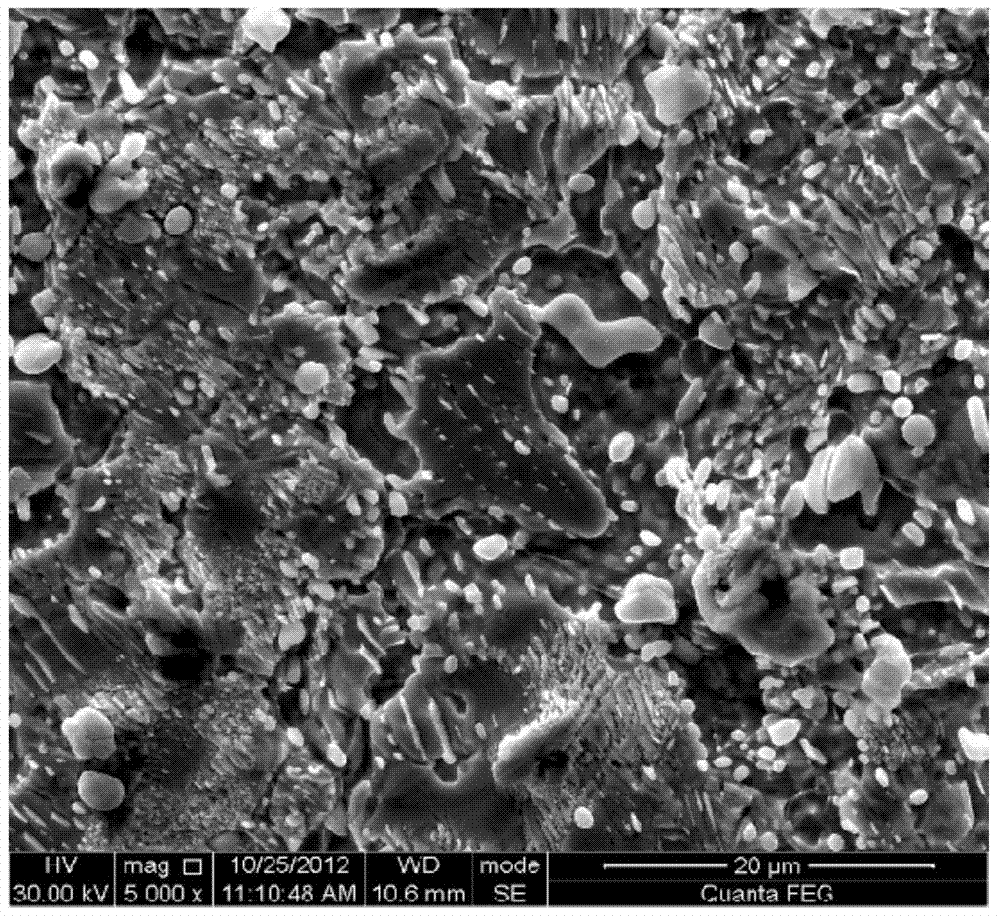

[0014] Specific embodiment 1: This embodiment is a method for grain refinement of the lead-tin alloy casting structure. The lead-tin alloy is only subjected to ultrasonic treatment in the preparation of the lead-tin alloy melt, and the lead-tin alloy is only poured in the lead-tin alloy melt. Ultrasonic treatment or lead-tin alloy is applied during the process of preparing the lead-tin alloy melt and the process of pouring the lead-tin alloy melt.

[0015] The advantage of this implementation mode:

[0016] One, this embodiment adopts the method of ultrasonic vibration to refine the casting microstructure of lead-tin alloy; due to the application characteristics of lead-tin alloy in the microelectronics industry, the amount of lead-tin alloy is very small when forming components each time, which is beneficial to Prevent the rapid attenuation of ultrasonic vibration in the alloy melt, and realize uniform vibration everywhere inside the lead-tin alloy melt;

[0017] 2. In this ...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the described lead-tin alloy only applies ultrasonic treatment in the preparation of the lead-tin alloy melt, which is completed according to the following steps:

[0022] 1. Melting and stirring the lead-tin alloy at a melting temperature of 400°C to 450°C to obtain a lead-tin alloy melt;

[0023] 2. Heat the lead-tin alloy melt at a temperature of 320°C to 380°C for 10 minutes to 30 minutes, then remove the scum on the surface of the lead-tin alloy melt, and obtain the lead-tin alloy melt after heat preservation and standing and removal of scale. body;

[0024] 3. Put the ultrasonic horn into the lead-tin alloy melt after heat preservation and standing and removing the scale, and then ultrasonically treat it for 50s~120s at the ultrasonic power of 200W~1000W and the ultrasonic frequency of 20000Hz~50000Hz to obtain ultrasonic waves. Treated lead-tin alloy melt;

[0025] 4. Po...

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the lead-tin alloy is only subjected to ultrasonic treatment during the pouring process of the lead-tin alloy melt, which is completed according to the following steps:

[0029] 1. Melting and stirring the lead-tin alloy at a melting temperature of 400°C to 450°C to obtain a lead-tin alloy melt;

[0030] 2. Heat the lead-tin alloy melt at a temperature of 320°C to 380°C for 10 minutes to 30 minutes, then remove the scum on the surface of the lead-tin alloy melt, and obtain the lead-tin alloy melt after heat preservation and standing and removal of scale. body;

[0031] 3. Apply the ultrasonic horn to the copper mold, and then pour the lead-tin alloy melt into the copper mold under the ultrasonic power of 200W ~ 1000W and the ultrasonic frequency of 20000Hz ~ 50000Hz. Cooling in the mold to obtain a lead-tin alloy ingot with refined grains, that is, a method for grain refinement of a lead...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com