Storage bin access control equipment and system

A warehouse and access control technology, applied in the field of warehouse access control equipment and systems, can solve the problems of manual opening/closing of locks, low efficiency, and error-prone manual warehouse confirmation, so as to reduce quality problems, save time, and avoid errors in warehouse selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

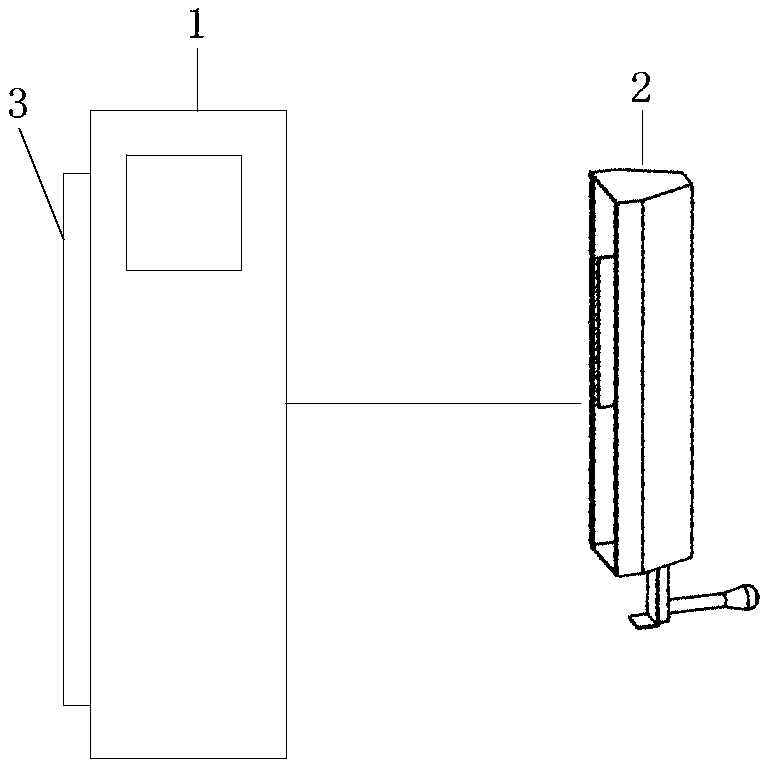

[0052] see figure 1 , The embodiment of the present invention provides a storage access control device, including an access control locker 1 and a storage lock 2; an indicator light 3 is arranged on the access control locker;

[0053] The access control locker 1 receives the unlocking signal transmitted by the PLC (Programmable Logic Controller, Programmable Logic Controller) control cabinet 4, and lights up the indicator light 3; the access control locker 1 supplies power for unlocking the position lock 2; the position lock 2 is powered by an external thrust The lock is unlocked under the action; the access control locker 1 receives the lock signal transmitted by the PLC control cabinet 4, and turns off the indicator light 3; the access control locker 1 provides power supply for the lock of the position lock 2, and the position lock 2 is locked under the action of gravity.

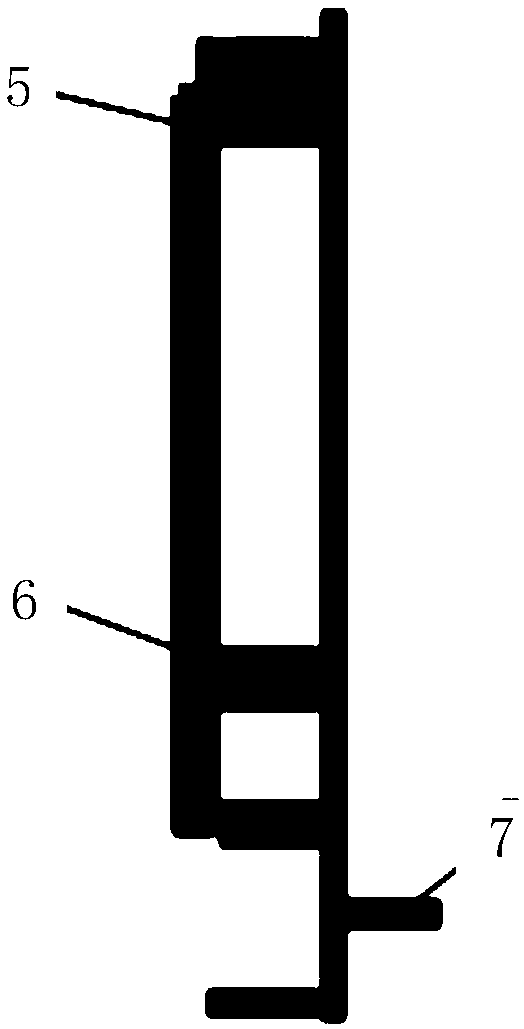

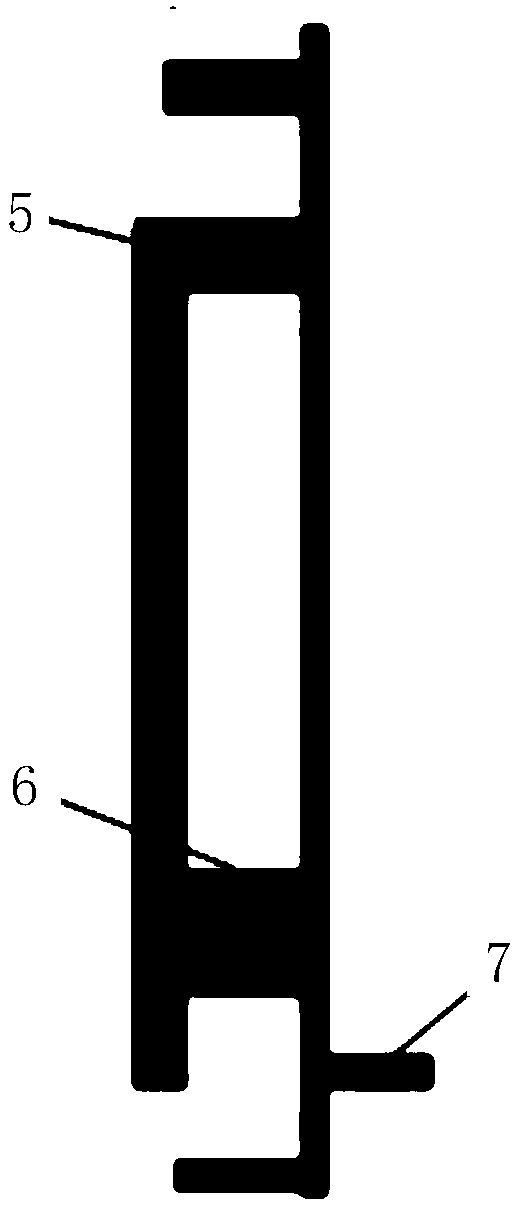

[0054] like figure 2 As shown, the position lock 2 includes an upper lock 5, a lower lock 6 and a ha...

Embodiment 2

[0067] see Image 6 , the embodiment of the present invention provides a warehouse access control system, including a warehouse distribution device 11, a PLC control cabinet 4 and a plurality of warehouse access control devices 12 provided in the above-mentioned embodiment 1; the PLC control cabinet 4 is connected with the warehouse distribution device 11 and multiple The position access control equipment 12 is connected; the position allocation device 11 identifies and verifies the type of raw material and user information; after the verification is passed, the unlocking instruction information is transmitted to the PLC control cabinet 4, and the unlocking instruction information includes the corresponding position identification of the raw material type; the PLC control cabinet 4 according to The unlock instruction information sends an unlock instruction to the warehouse access control device 12 corresponding to the warehouse identifier.

[0068] The structure and compositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com