Inclined turnover filter device and filtering method

A technology of a filtering device and a filtering method, which is applied in the directions of stationary filter element filters, filtration separation, and filtration treatment, can solve the problems of clogging the filter screen, waste of manpower and material resources, and accumulation of dirt, etc., and achieves high practical value and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

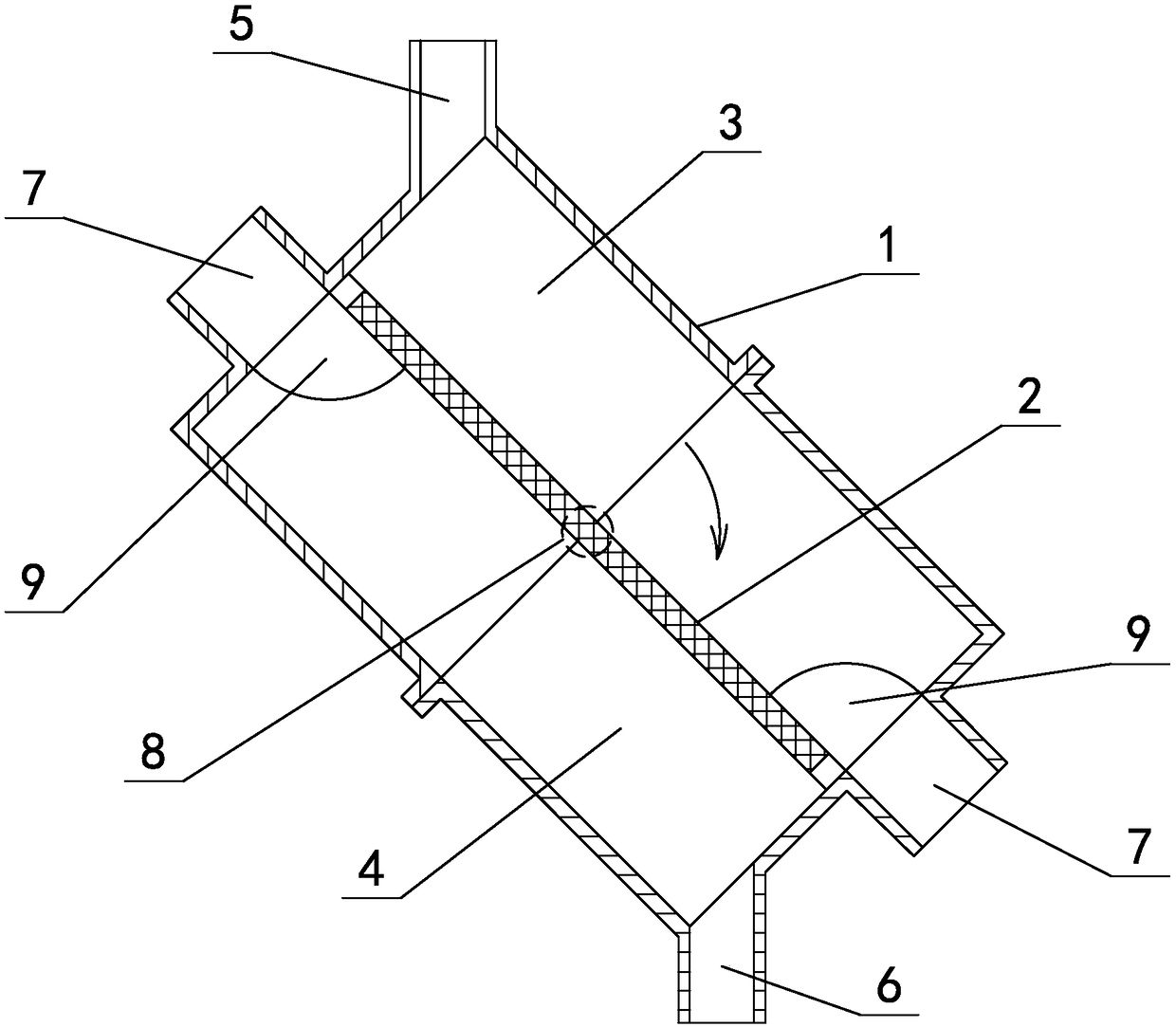

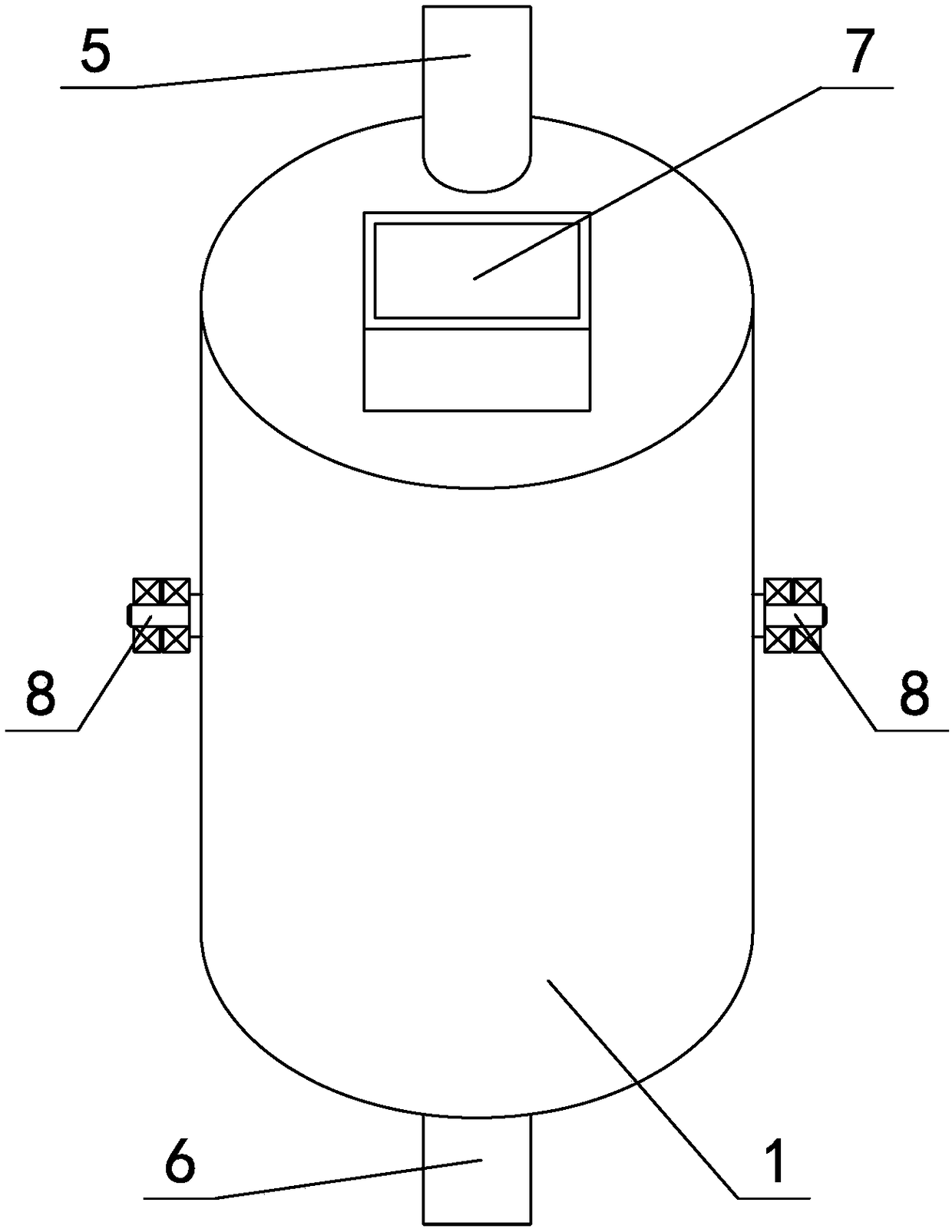

[0027] in such as figure 1 In the shown embodiment 1, an inclined reversible filter device includes an inclined cylinder 1 and a filter plate 2 arranged in the cylinder, and the angle between the axial direction of the cylinder and the horizontal plane is 45 to 60 degrees (45 degrees in this embodiment), the filter plate includes a rectangular frame and a filter screen arranged in the frame, the rectangular frame is fixed on the axial center surface of the cylinder, the filter plate The outer edge is in close contact with the inner wall of the cylinder. The inner cavity of the cylinder above the filter plate forms the water inlet cavity 3, and the inner cavity of the cylinder below the filter plate forms the water outlet cavity 4. There is an inlet cavity on the side of the upper end of the cylinder. The water inlet 5 is provided with a water outlet 6 on one side of the water inlet cavity on the lower end surface of the cylinder, the water inlet is arranged on the upper edge o...

Embodiment 2

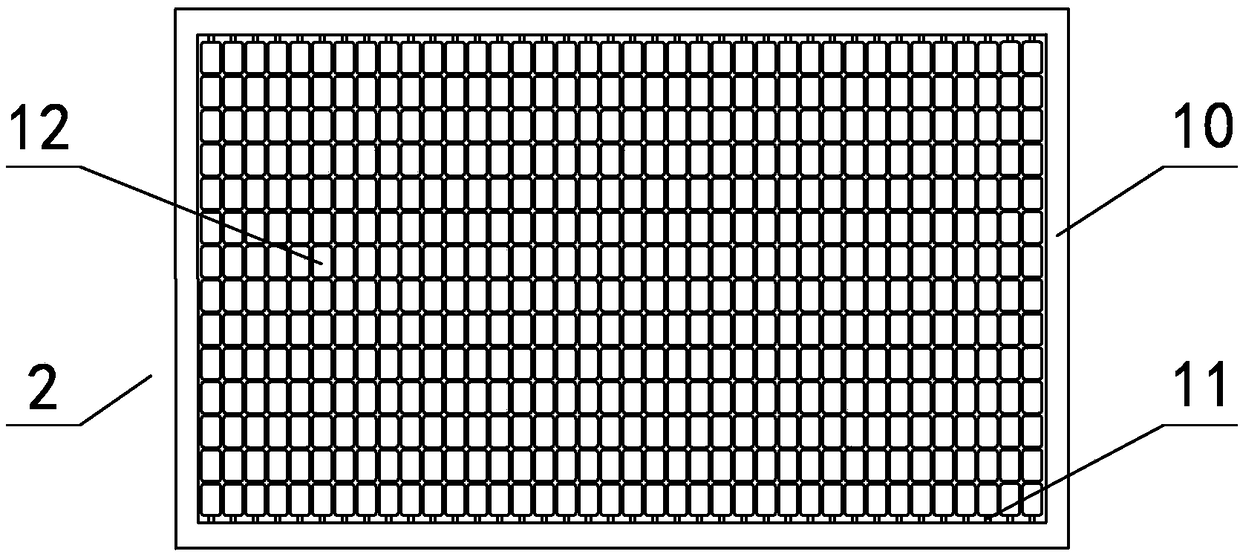

[0035] in such as image 3 In the shown embodiment 2, the filter plate includes a rectangular surrounding frame 10 and a filter screen arranged in the surrounding frame. Roller 12, grid-shaped backguy equidistantly arranges, and every grid-shaped backguy is all provided with a plurality of cylindrical rollers (see Figure 4 ), and the rest are the same as in Example 1.

[0036] The filtering method of the inclined type reversible filter device of embodiment 2, except the step of embodiment 1, also comprises the following steps:

[0037] f. When the sundries above the filter plate fall down along the slope of the filter plate, the rollers roll.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com