Numerical control fixed-torque intelligent electric wrench

An electric wrench and constant torque technology, applied in the directions of wrenches, power tools, wrenches, etc., can solve the problems of unsatisfactory performance of constant torque electric wrenches, low level of quality management informatization, and difficulty in ensuring construction quality, so as to eliminate the need for calibration. Work, simplify the construction process, and save the effect of torque inspection work after final screwing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

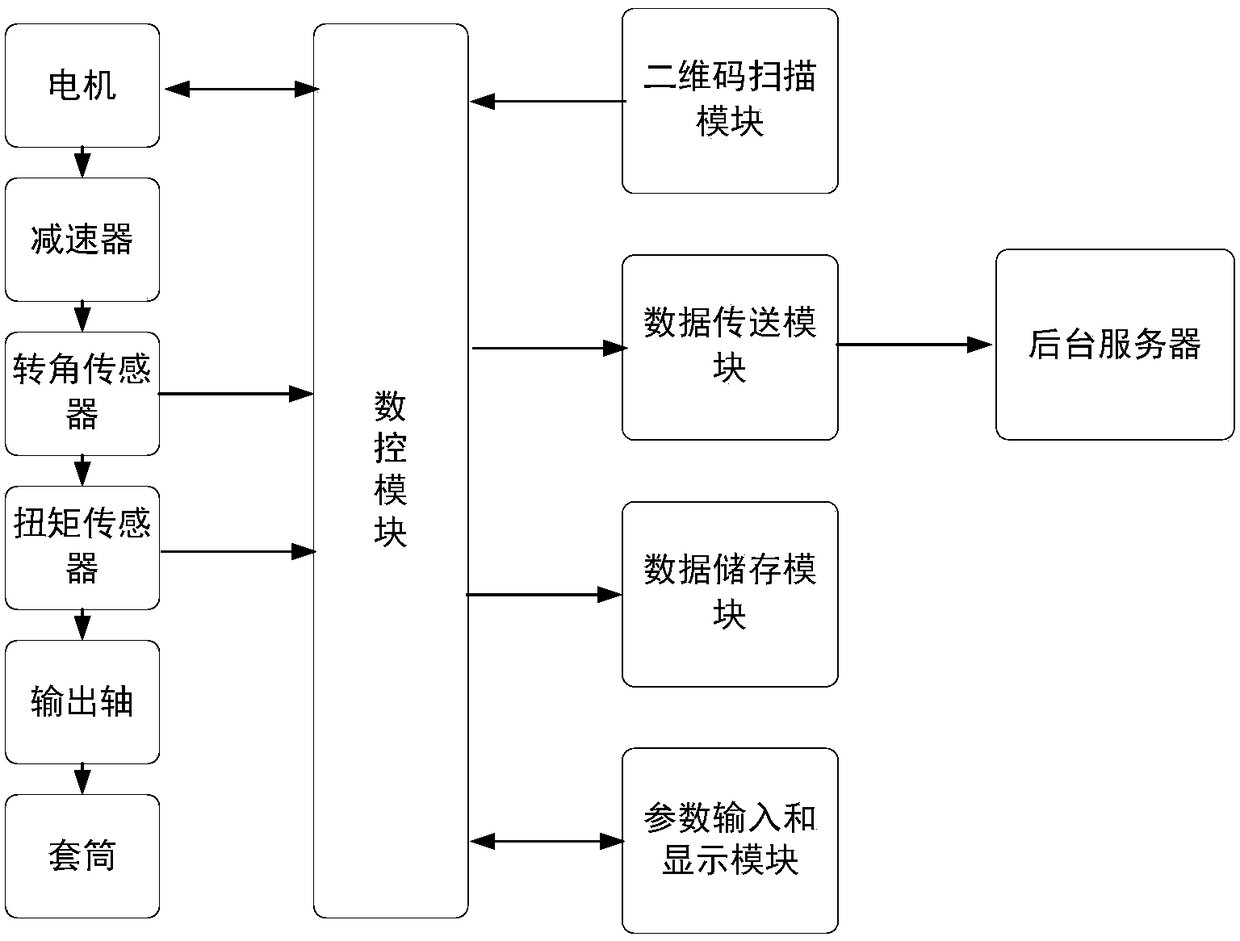

[0028] Such as figure 1 As shown, a numerical control fixed torque intelligent electric wrench, the wrench includes: parameter input and display module, two-dimensional code scanning module, motor, reducer, output shaft and sleeve, torque sensor, rotation angle sensor, numerical control module, data transmission modules and data storage modules;

[0029] The parameter input and display module is used to preset tightening parameters, display tightening results and prompt operation information;

[0030] The two-dimensional code scanning module is used to identify the current operator and the content of the construction plan;

[0031] The content of the construction plan includes: planned operator, bolt area location, bolt quantity, bolt type, screwing method, preset torque, bolt batch number, bolt average torque coefficient, construction stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com