Gantry frame vehicle logistics supplying-route system used for vehicle main engine plants and spare parts manufacturers

A gantry frame and logistics technology, applied in the field of gantry frame car logistics supply line system, can solve the problems of high turning space requirements of logistics channels, limited number of logistics supply line cars, large turning radius, etc., to achieve flexible positioning and long service life Long, small turning radius effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

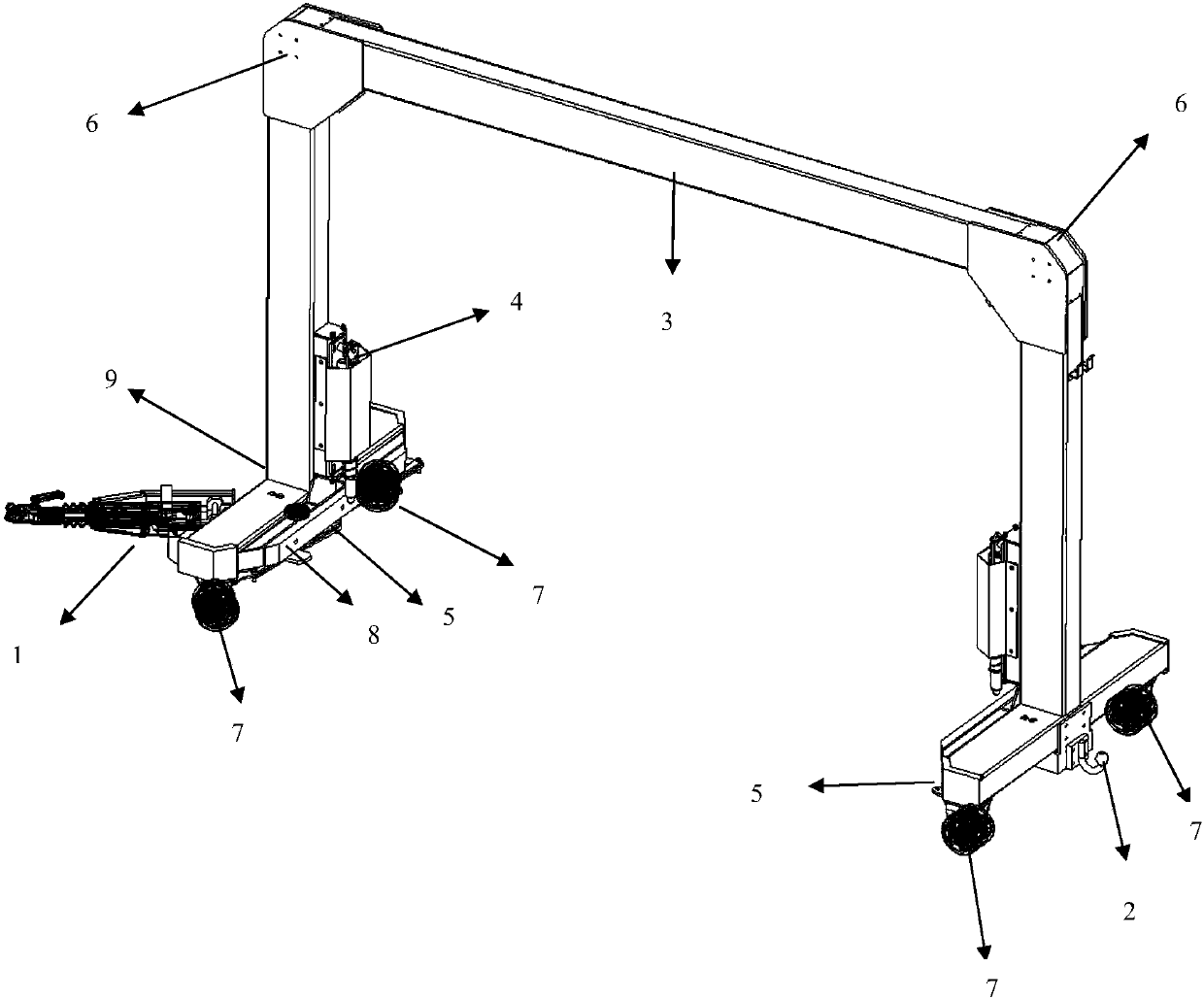

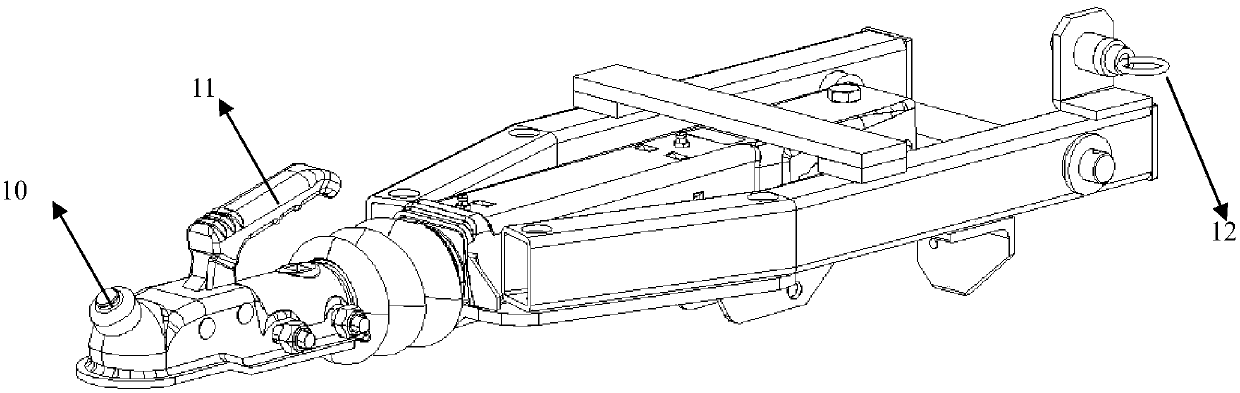

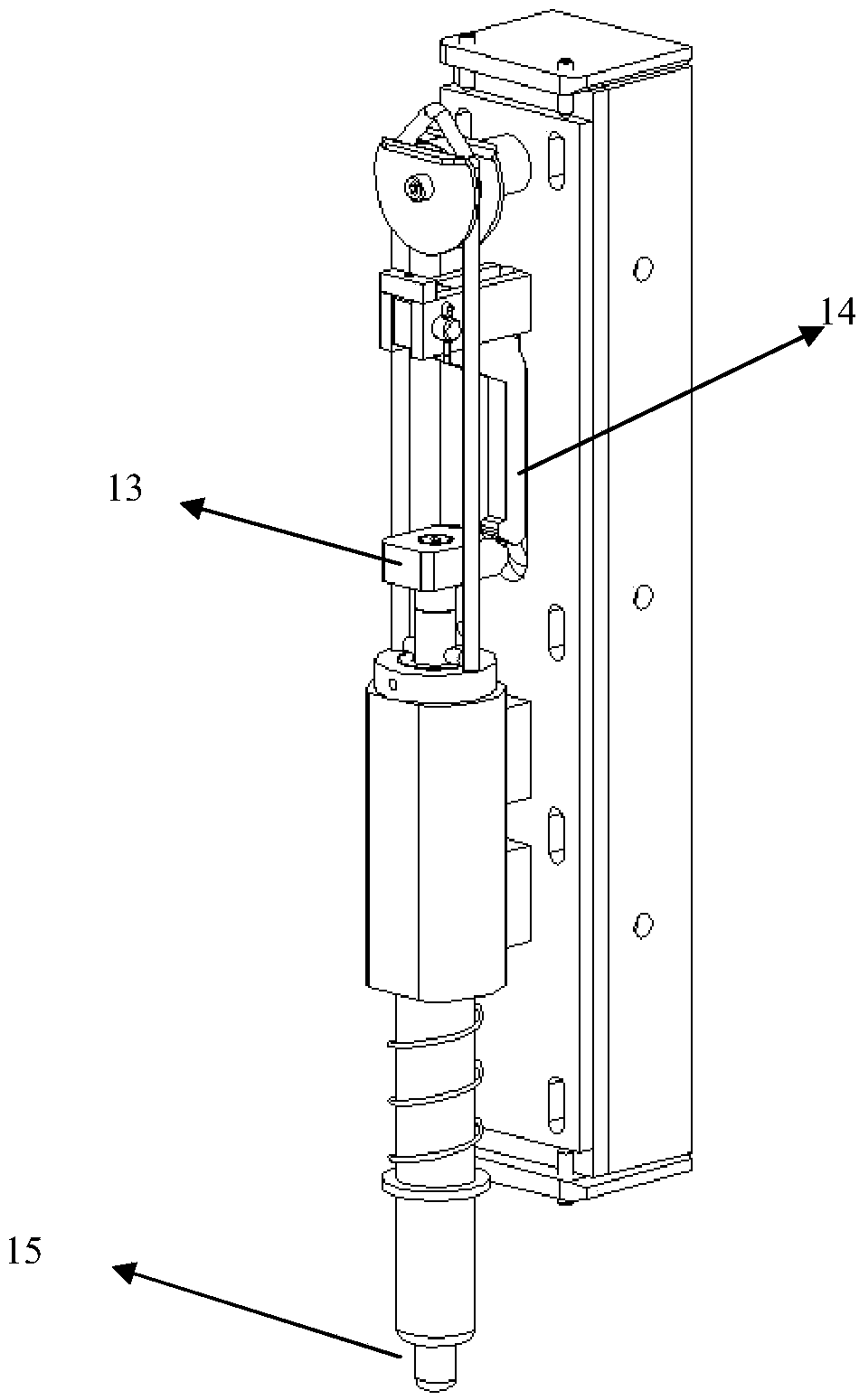

[0026] A logistics line supply system for a gantry frame vehicle, the structure includes: a front traction assembly 1, a rear towing hook 2, a main beam assembly 3, an intelligent locking assembly 4, a caster steering control assembly 5, a steering assembly 6, a caster assembly 7, an anti Strike block assembly 8, RFID traceability chip 9.

[0027] The front traction assembly 1 can be connected with the tow hook of the power trailer, and the rear tow hook 2 of another gantry frame car, so as to realize the function that multiple gantry frame cars can be connected in series, and the number of single pulls is large. Three groups of main girder components constitute the overall shape of ┏┓-shape when viewed from the front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com