Gill type cyanobacterial harvesting ship

A technology of cyanobacteria and fish gills, which is used in fixed filter element filters, water/sludge/sewage treatment, filtration and separation, etc., can solve the problems of clogging of the collection device, inconvenient operation, and no setting, etc., to prevent the center of gravity from shifting, The effect of reducing workload and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

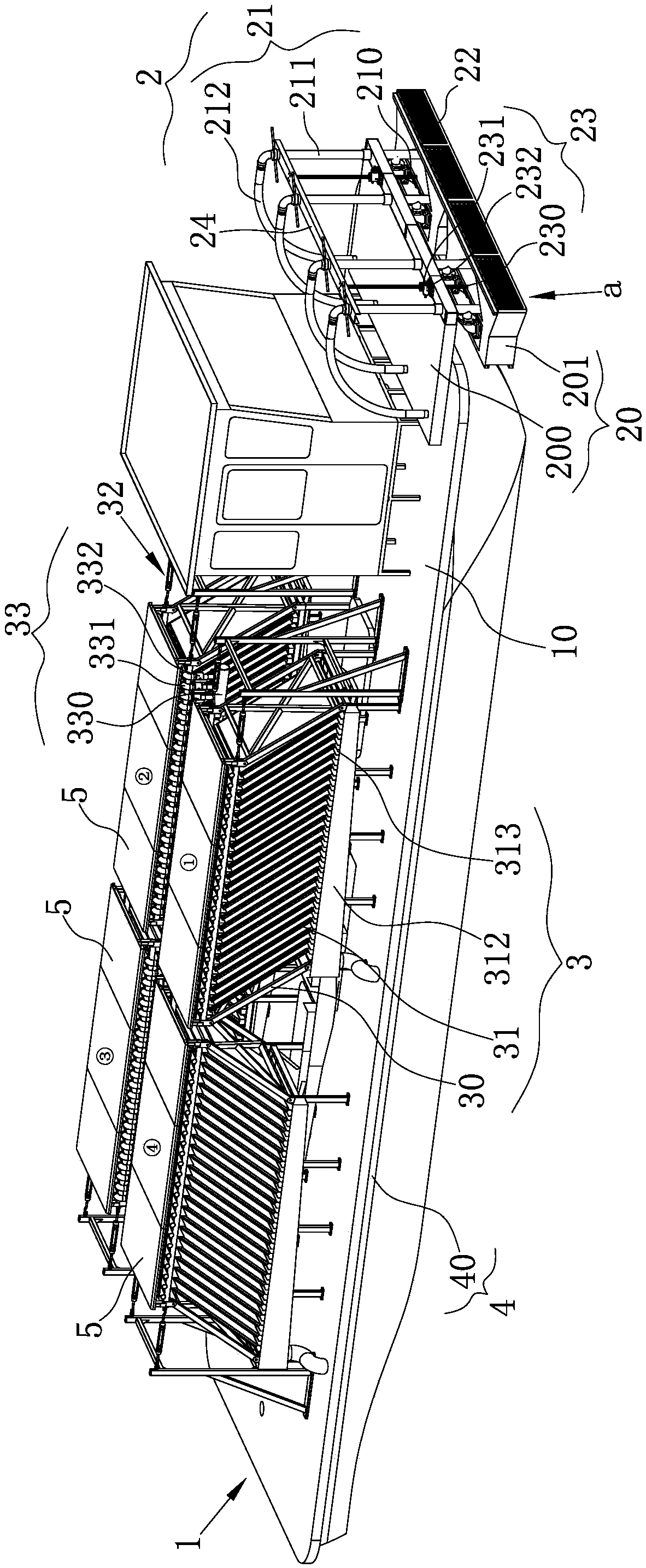

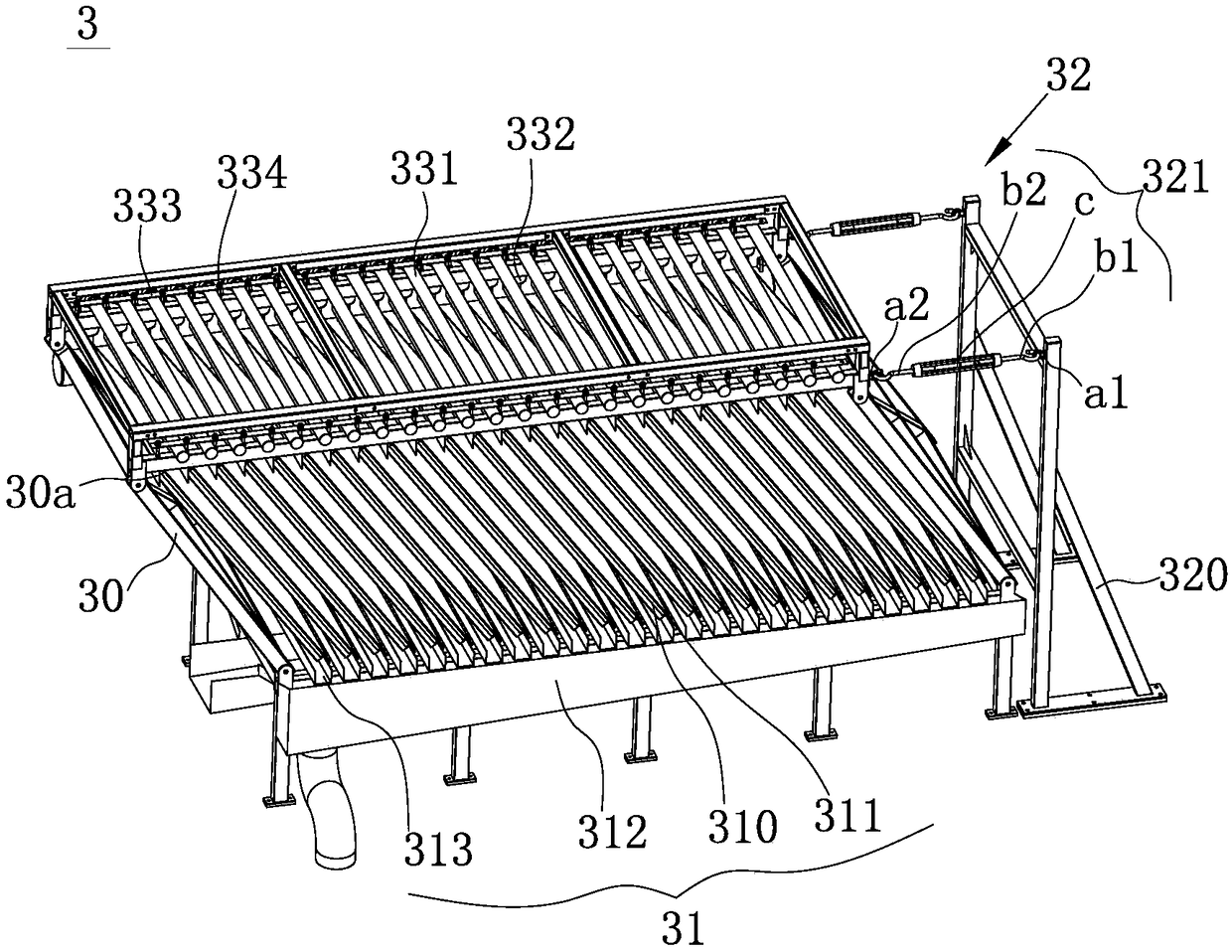

[0037] see figure 1 The cyanobacteria harvesting ship provided in this embodiment includes a hull 1, a cyanobacteria collection device 2, a gill type filter device 3, and a storage device 4, wherein there are multiple gill type filter devices 3, and they all incline to the middle of the hull 1 and move closer to the settings.

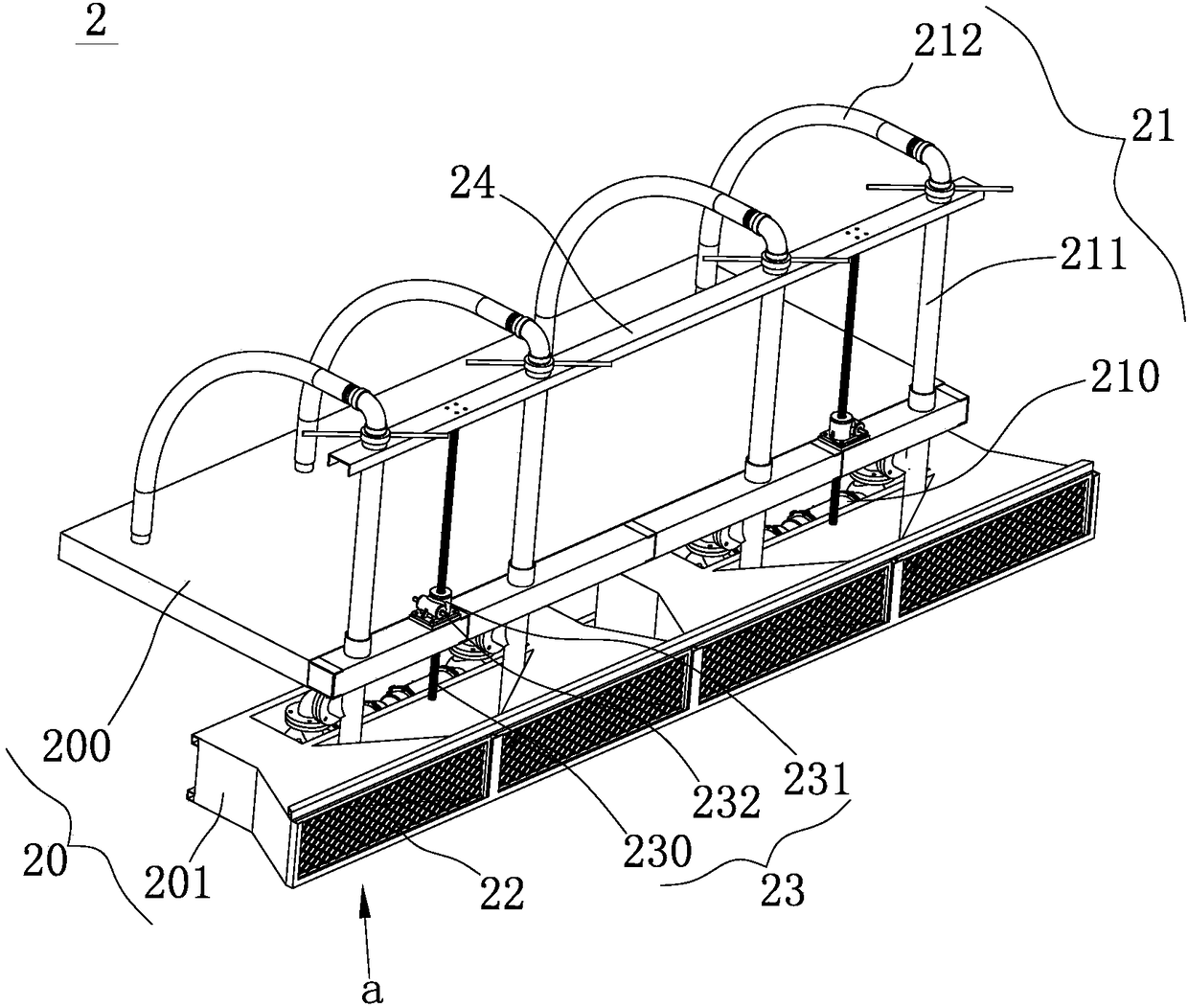

[0038] Specifically, see figure 1 and figure 2 , in this example, the cyanobacteria collection device 2 is located at the bow, and includes a support 20 positioned at the bow, a submersible pump assembly 21 and an interception net 22 arranged on the support 20, wherein the submersible pump assembly 21 and the interception net 22 form A collection unit a.

[0039] In this example, the collection unit a can be adjusted up and down along the height direction of the hull 1 .

[0040] The bracket 20 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com