Electrocatalysis nitric acid treatment device

A treatment equipment and electrocatalytic technology, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve the problem of not being able to detect the pH of ammonia nitrogen water well, and not being able to better control the oxidant The amount of addition, the recovery of waste residue that is not enough to discharge, etc., achieve the effect of good environmental protection, convenient operation, and thorough transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

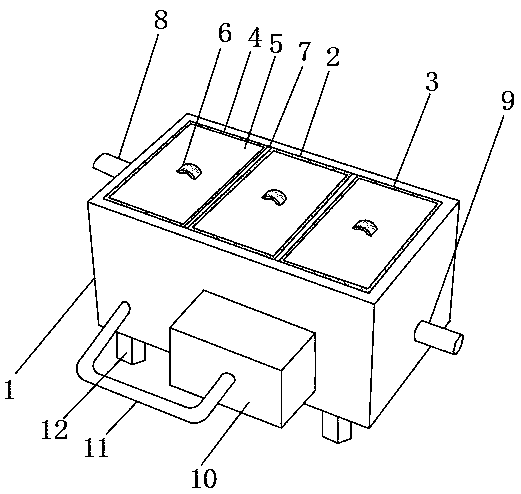

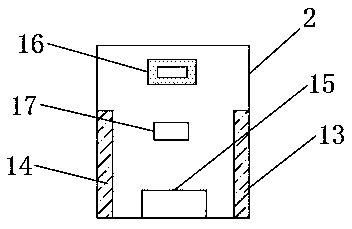

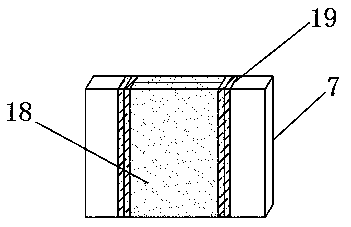

[0017] Such as Figure 1-3 As shown, an electrocatalytic ammonia nitrogen water treatment device includes a device main body 1, an electrocatalytic cell 2 is fixedly installed in the middle of the device main body 1, a detection cell 3 is fixedly installed on one side of the electrocatalytic cell 2, and an electrocatalytic cell 2 A filter pool 4 is fixedly installed on one side of the filter pool 4, and a cover plate 5 is movably installed on the outer surface of the upper end of the filter pool 4, and a handle 6 is fixedly installed in the middle of the upper end outer surface of the cover plate 5, between the electrocatalytic cell 2 and the filter pool 4 An isolation plate 7 is fixedly installed, an ammonia nitrogen water inlet pipe 8 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com