Aquatic product feed processing device for groupers

A technology for aquatic feed and processing equipment, which is applied in the direction of feed, dry solid materials, lighting and heating equipment, etc. It can solve the problems of no scraper, no knife, and the inability to reasonably control the size of feed particles, so as to avoid mildew, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

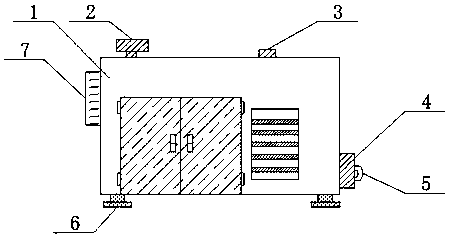

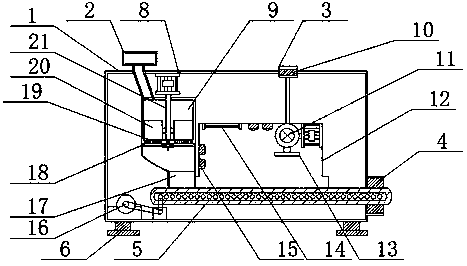

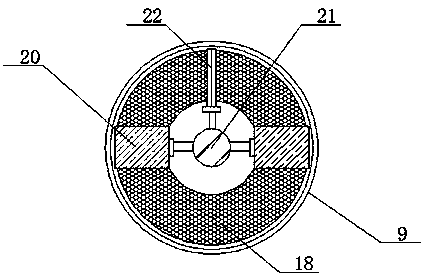

[0028] Example: such as Figure 1-6 As shown, the present invention provides a kind of technical scheme, a kind of aquatic feed processing device of grouper, comprises feed pellet machine 1, and the upper end of 1 is provided with hopper 2, and one end of feed pellet machine 1 is provided with control switch 7, hopper One side of the feed pellet machine 1 is provided with an exhaust port 3, the lower end of the feed pellet machine 1 is provided with a support foot 6, and the other end of the feed pellet machine 1 is provided with a discharge port 4, and a conveyor 5 is installed inside the feed pellet machine 1. The top of the conveyor 5 is provided with a protective material box 17, and a second motor 16 is installed on one side of the conveyor 5, the top of the protective material box 17 is provided with a granulation bucket 9, and one side of the protective material box 17 is provided with a row Fan 12, the lower end of granulation barrel 9 is provided with particle templat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com