Coaxial structural uniform flow cavity for sterilization of high voltage pulse electric field

A technology of high-voltage pulsed electric field and coaxial structure, which is applied in sanitary equipment for toilets, water supply devices, buildings, etc., can solve the problems of small processing capacity and low processing efficiency, and achieve the goal of preventing electric field distortion, improving processing efficiency, and improving extinction The effect of bacterial treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

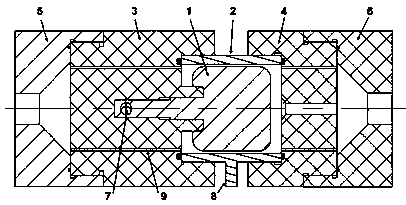

[0023] Such as figure 1 As shown, the present invention mainly consists of a high-voltage electrode 1, a ground electrode 2, a front uniform flow chamber 3, a rear uniform flow chamber 4, a front transition chamber 5 and a rear transition chamber 6, a high-voltage electrode lead-out electrode 7, and a ground electrode lead-out Electrode 8, uniform flow small hole 9 and other components. The high-voltage electrode 1 is threaded at the position of the boss in the front uniform flow chamber 3 and sealed with a rubber ring, and at the same time plays a fixing role. The ground electrode 2 is a hollow ring, forming a coaxial cavity structure with the high voltage electrode 1 . The ground electrode lead-out electrode 8 is connected to the middle position of the outer end of the ground electrode 2 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com