Flue gas and water same-channel dust-removing device

A technology of dust removal device and water outlet device, applied in the direction of using liquid separation agent, gas treatment, membrane technology, etc., can solve the problems of insufficient spray water line density, reduced dust removal effect, poor smoke exhaust, etc., to achieve the best dust removal effect, Improve the dust removal effect, increase the effect of contact area and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be specifically described below in conjunction with the accompanying drawings and embodiments. However, the examples described below are for better elaboration of this patent, and are not intended to limit the protection scope of this patent.

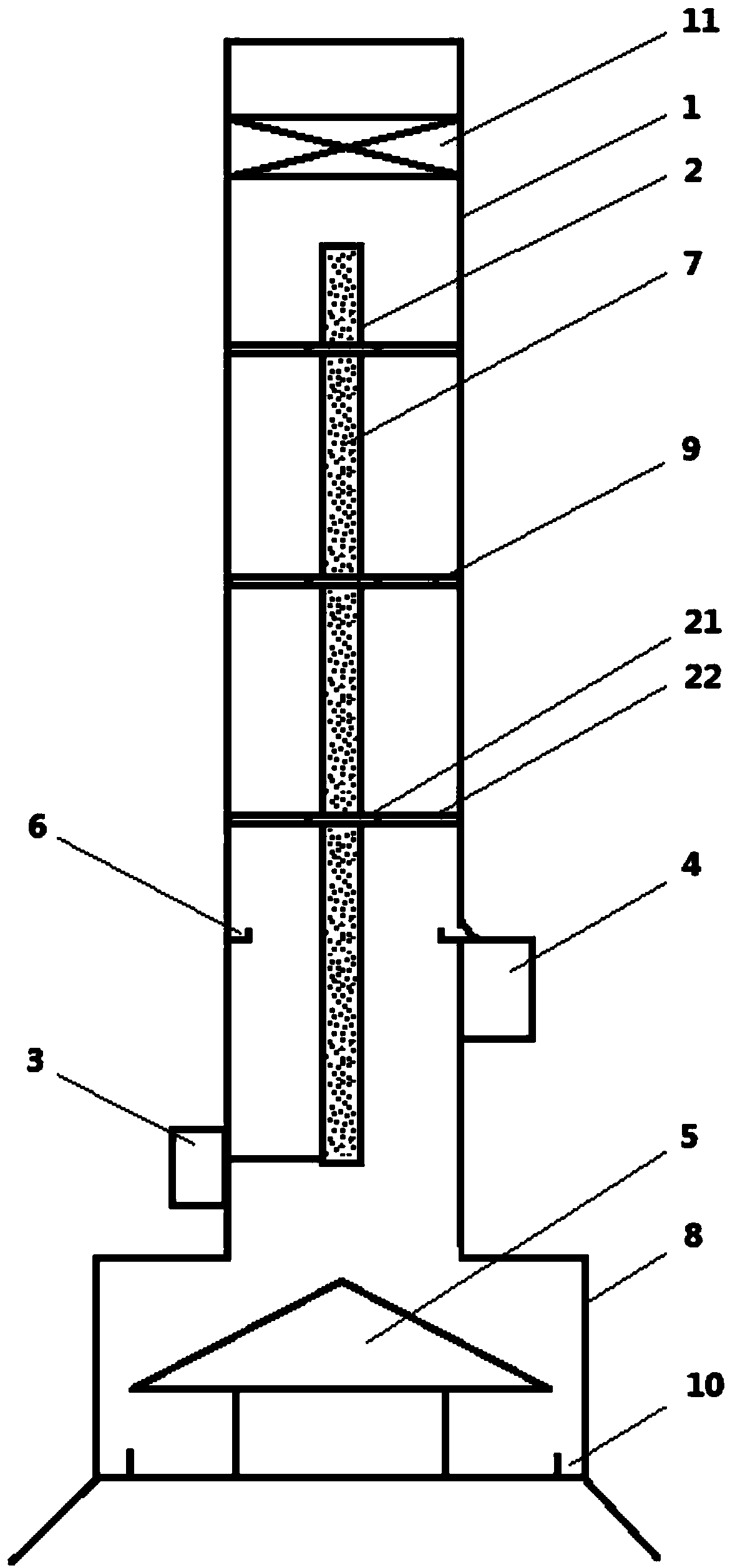

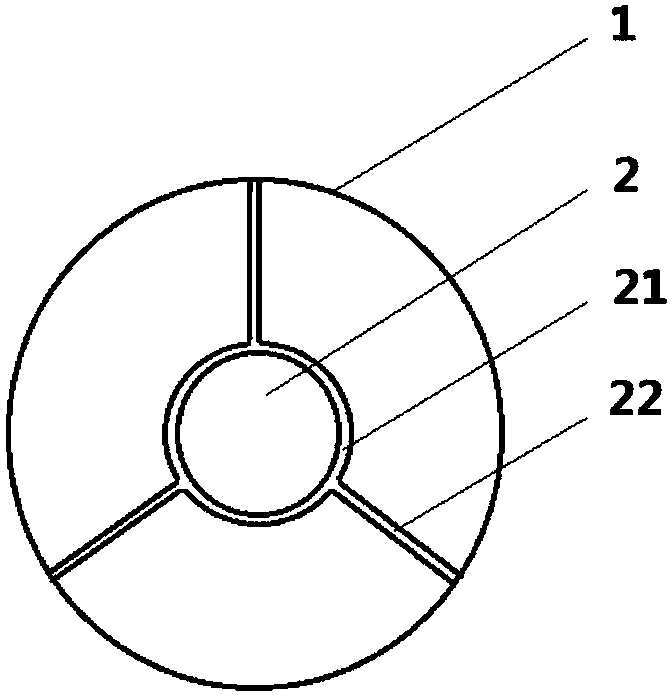

[0025] Such as figure 1 As shown, the smoke and water co-channel dedusting device includes a chimney, a water channel, a water inlet device, a water outlet device and a conical drainage cover. Wherein, the inner wall of the chimney is made of metal pipe or metal material, and one or more water channels are longitudinally arranged inside the chimney. The water channel is a tubular structure, and one, two, three or more water channels can be set according to the inner diameter of the chimney. When there are multiple water channels, the multiple water channels are located at the center of the chimney.

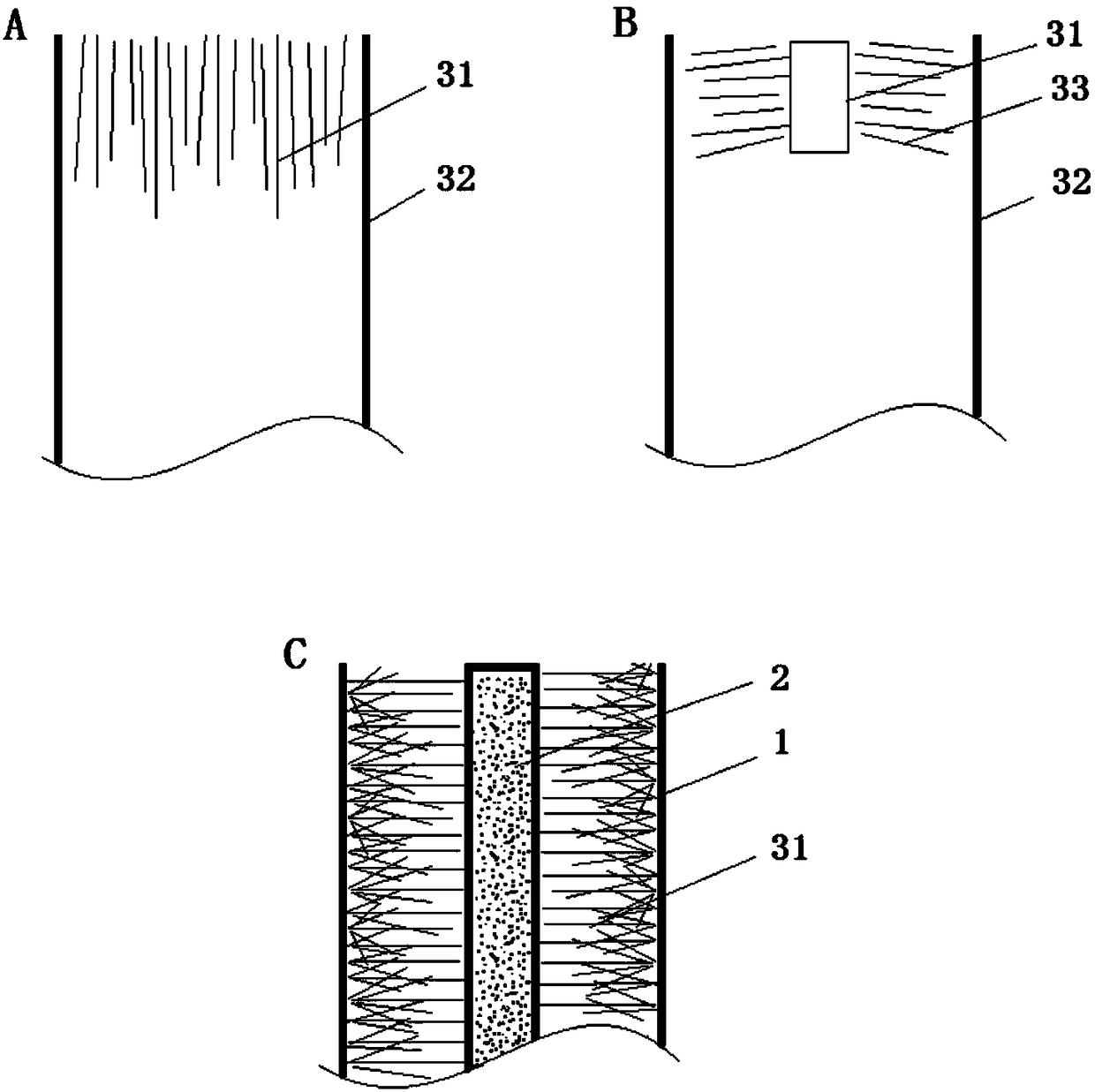

[0026] The pipe wall of the water channel is provided with a plurality of horizontal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com