Automatic paint spraying production line and paint spraying process thereof

An automatic painting and production line technology, applied in the direction of spraying device, electrostatic spraying device, pretreatment surface, etc., can solve the problems of high cost, poor painting effect and waste of round-edged plate parts, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

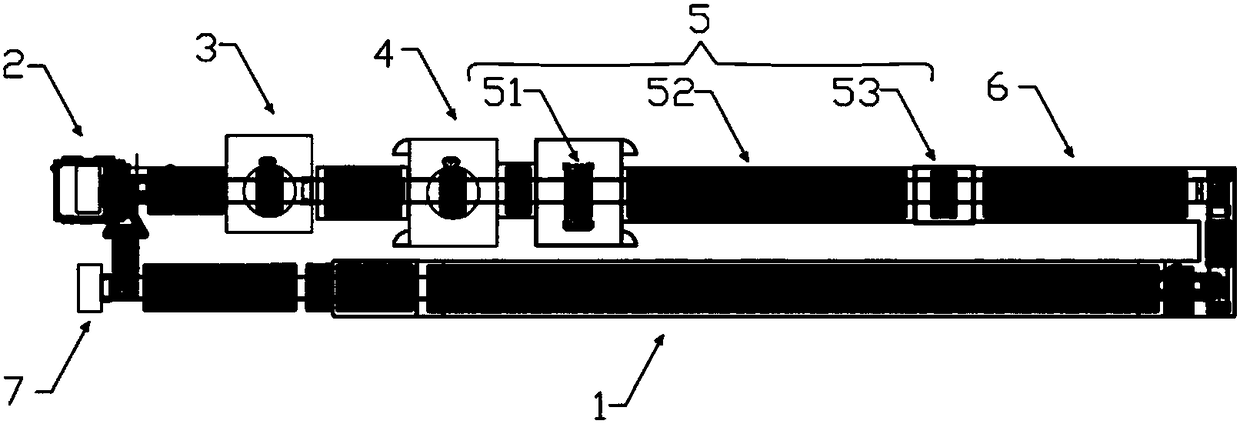

[0027] Such as figure 1 As shown, an automatic painting production line includes a double-speed chain body 1, and also includes an on-line mechanism 2 connected sequentially through the double-speed chain body 1, a dust removal mechanism 3 for removing dust from the workpiece, and a preheating mechanism for heating the outer surface of the workpiece. And repair the color correction mechanism 4 of the color difference of the spray paint, the paint spray mechanism 5 that sprays the paint on the surface of the workpiece and dry it, the cooling mechanism 6 that cools the workpiece, and the offline mechanism 7.

[0028] In the production line of this embodiment, the paint spraying mechanism 5 includes an electrostatic sprayer 51 connected in sequence to spray paint on the workpiece, a leveling surface dry tunnel 52 with constant temperature, constant pressure, dust-free positive pressure, and a curing device for curing the paint on the surface of the workpiece 53.

[0029] Adopt a...

Embodiment 2

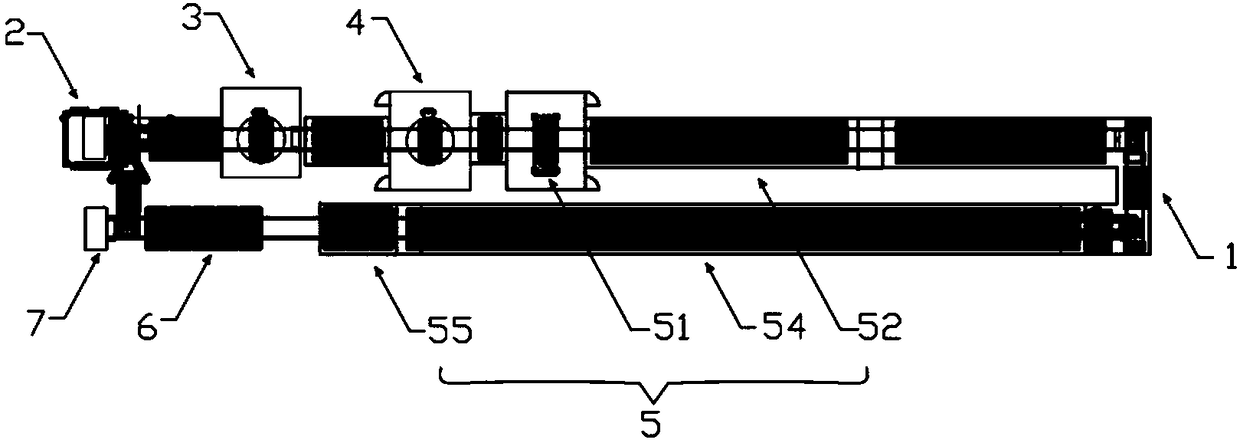

[0037] Such as figure 2 As shown, the paint spraying mechanism 5 in this embodiment includes an electrostatic sprayer 51 connected successively to spray the paint onto the workpiece, a leveling surface dry tunnel 52 with constant temperature, constant pressure, dust-free positive pressure, and a water absorption in the spray paint. The microwave drying area 54 that goes away and the infrared drying area 55 that spray paint is dried.

[0038] Adopt a kind of spraying process of production line in the present embodiment, this process is applicable to water-based paint, and comprises the following steps: Step 1, the workpiece that has sprayed primer is placed on the tooling plate of on-line mechanism 2, double-speed chain line body 1 Start the operation, and send the workpiece to the dust removal mechanism 3 for dust cleaning; step 2, send the workpiece to the color repair mechanism 4 for preheating, and manually repair the color difference of spray paint on the transition part ...

Embodiment 3

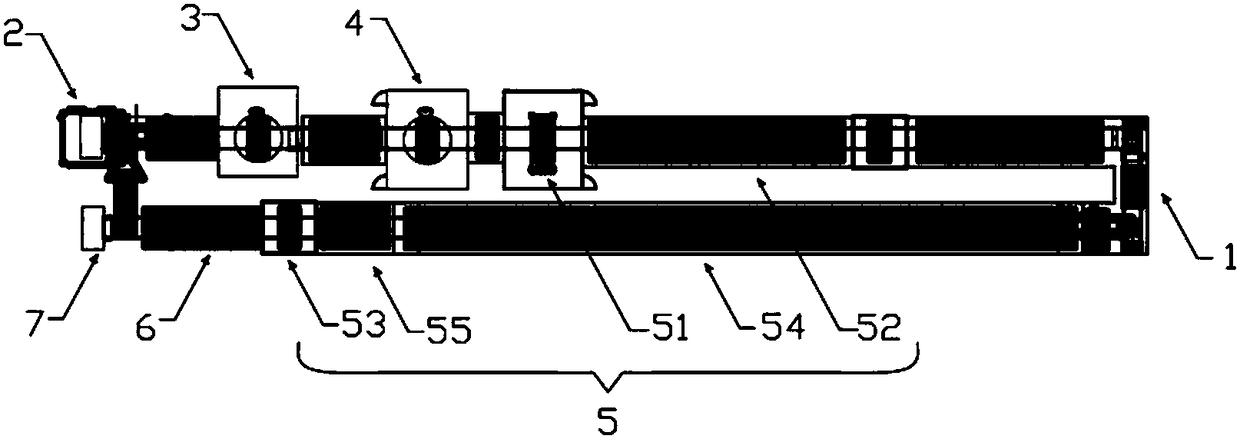

[0044] Such as image 3 As shown, the paint spraying mechanism 5 in this embodiment includes an electrostatic sprayer 51 connected successively to spray the paint on the workpiece, a leveling surface dry tunnel 52 with constant temperature, constant pressure, dust-free positive pressure, and a water-based paint. A microwave drying zone 54 for suction, an infrared drying zone 55 for drying the water-based paint, and a curing device 53 for curing the water-based paint on the workpiece surface.

[0045] Adopt a kind of spraying process of production line in the present embodiment, this process is applicable to water-based UV paint, and comprises the following steps: step 1, the workpiece that has sprayed primer is placed on the tooling plate of on-line mechanism 2, double speed chain line body 1 Start the operation, and send the workpiece to the dust removal mechanism 3 for dust cleaning; step 2, send the workpiece to the color repair mechanism 4 for preheating, and manually repa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com