Aluminum alloy pipe fitting surface spraying device

A surface spraying, aluminum alloy technology, applied in the field of aluminum alloy processing, can solve the problems of low spraying efficiency, incomplete process, and the spraying does not have aesthetics, so as to improve the spraying effect, improve the processing effect, and improve the processing and spraying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

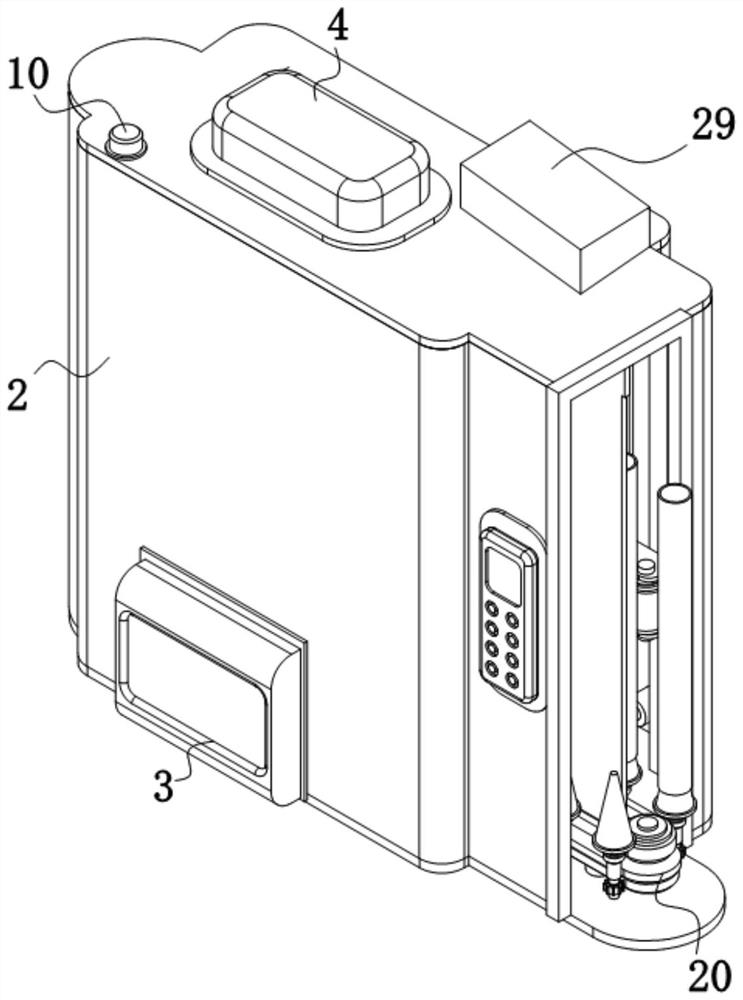

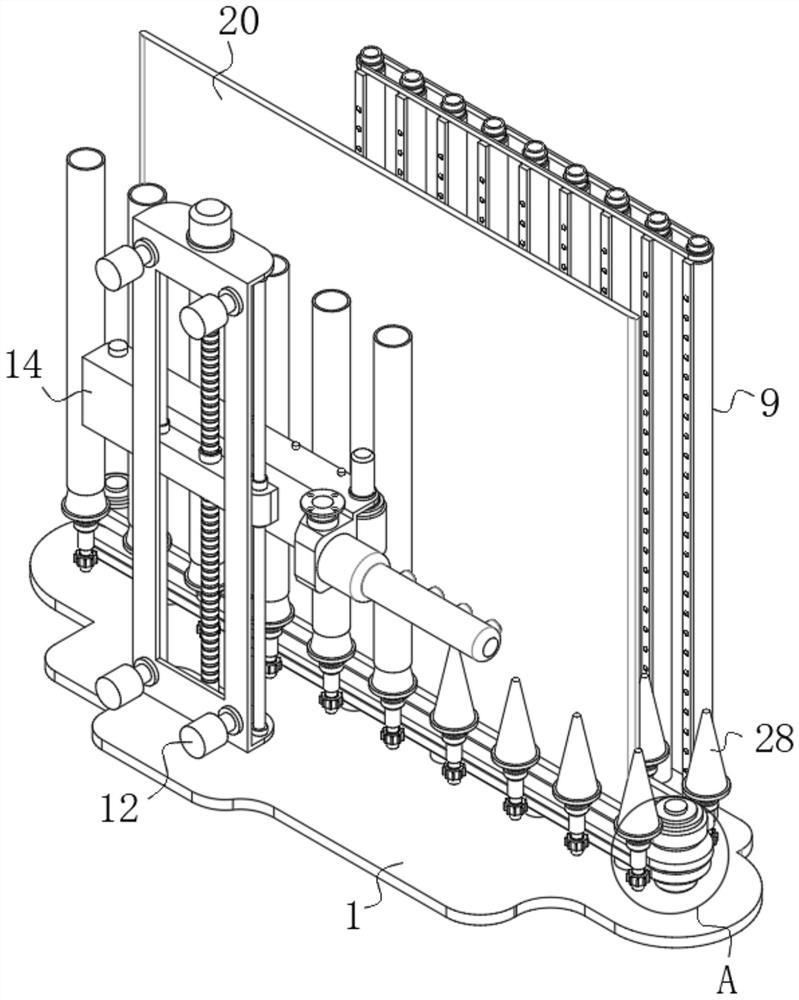

[0035] Such as Figure 1-Figure 7 As shown, the present invention provides a surface spraying device for aluminum alloy pipe fittings. Pipe 8, one end of the air outlet of the hot-blast generating mechanism 3 is fixedly communicated with the air-distributing pipe 8, and the other end of the air-distributing pipe 8 is provided with a connecting pipe, and the top of the connecting pipe is connected with a plurality of hot-blast nozzles 9 in rotation, and the hot-blast generating mechanism 3 is The hot blast supply source of the hot blast nozzle 9, the hot blast generating mechanism 3 includes a hot blast generating box, one end of the hot blast generating box air inlet is fixedly communicated with the housing 2, and one end of the hot blast generating box air outlet is communicated with the air distribution pipe 8, and the hot blast generates The inside of the box is equipped with a fan and a heating wire, and a temperature sensor is installed on the side of the air outlet of th...

no. 2 example

[0042] Basically, the first embodiment provides a surface spraying device for aluminum alloy pipe fittings. During the working process of the device, since the up and down movement speed of the grinding seat 14 is uncertain, whether the aluminum alloy pipe fittings can be adapted to the surface when passing through the grinding station and the spraying station height, and it is thoroughly and uniformly polished and sprayed. At the same time, when the aluminum alloy pipe fittings enter the spraying station, their own radius will cause a certain amount of occlusion to the spraying width of the nozzles 30, so that the range of spraying by multiple nozzles 30 is not in the horizontal direction. continuous, resulting in spraying gap faults, which greatly affects the spraying effect and causes discontinuity in the spraying of aluminum alloy pipe fittings. It is an integer multiple, so that the spraying effect is affected by the uneven spraying thickness, and the waste of spraying dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com